Small-sized precision squeeze riveter

A press riveting machine, precise technology, applied in the field of small precision riveting machines, can solve the problems of loud noise and vibration, inconvenient movement, high cost, etc., achieve the effect of controllable pressure and stroke, save material and space, and be easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

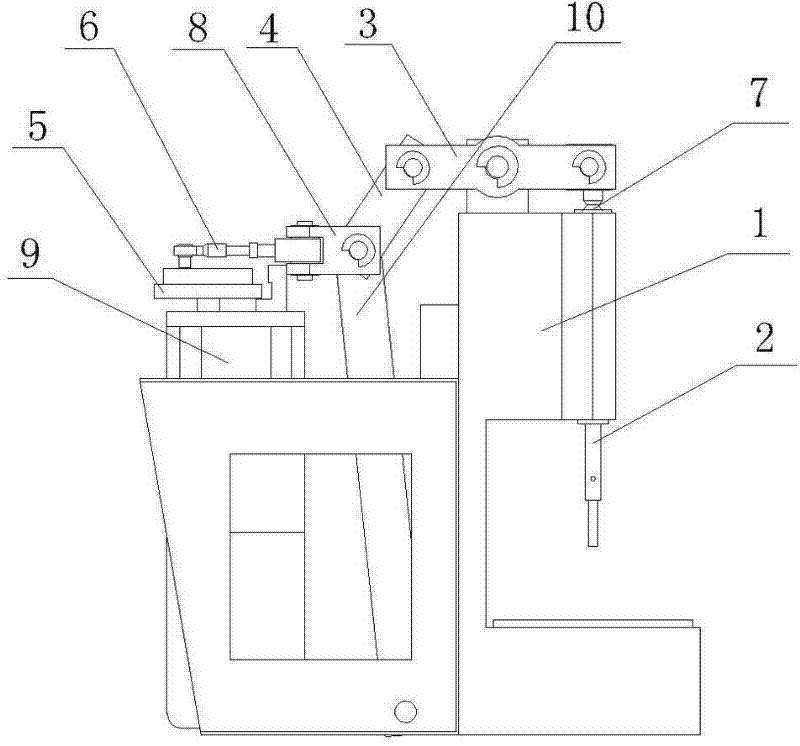

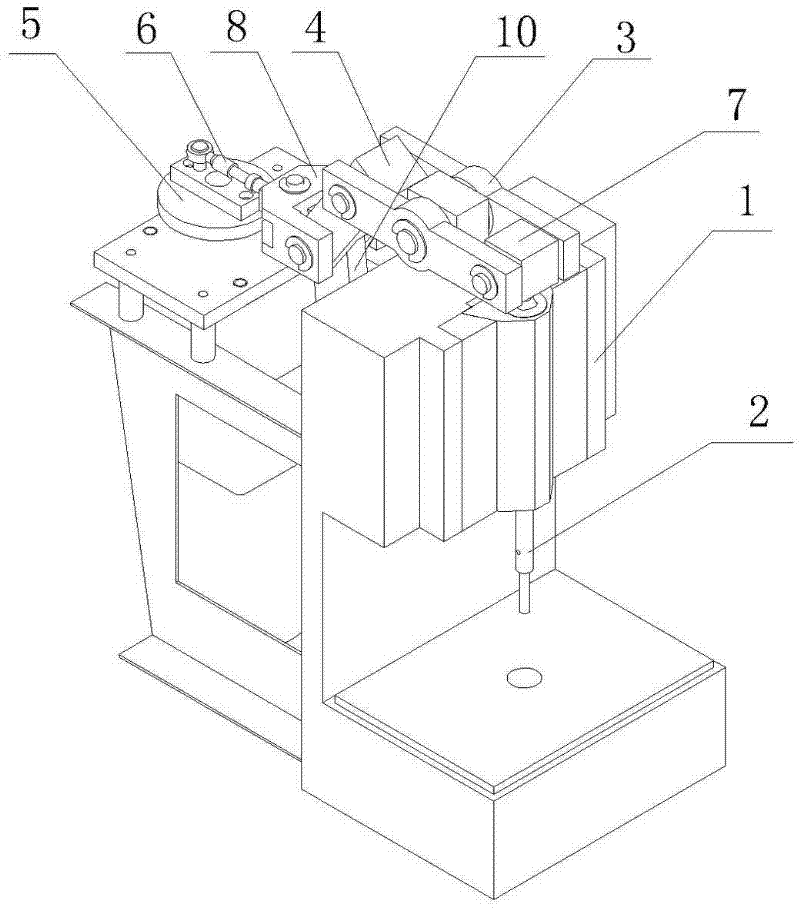

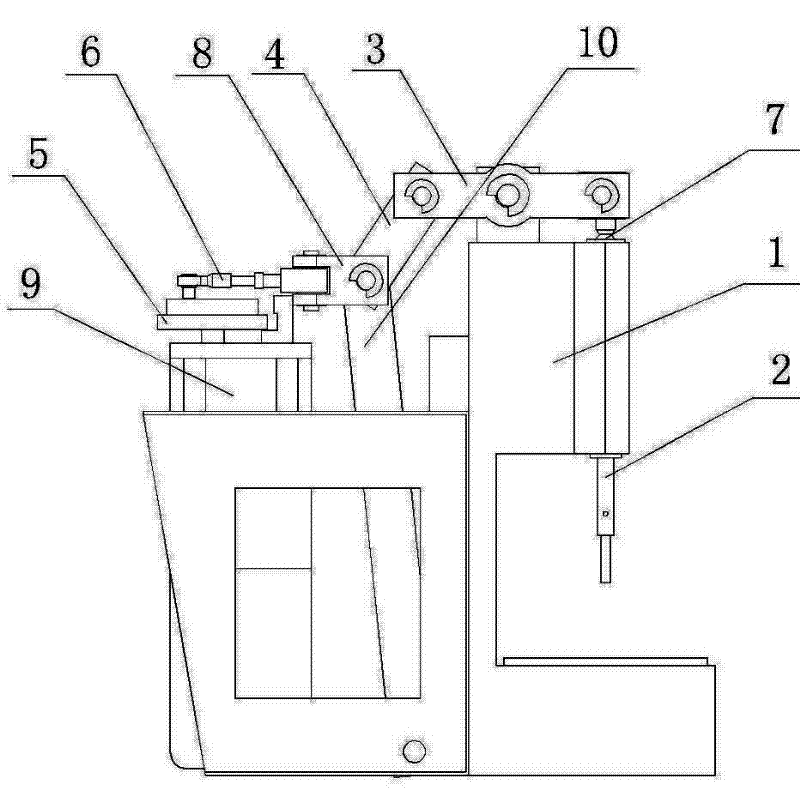

[0026] Such as figure 1 , figure 2 As shown, the present invention includes a fuselage and a control system. The fuselage 1 is provided with a slider 2, a link arm 3, an output rod 4, a toggle joint 8 and a power unit 9, and the slider 2 passes through a universal The connecting head 7 is hinged with one end of the link arm 3, and the universal joint 7 can make the movement between the slider 2 and the link arm 3 more flexible, while improving the movement accuracy and Energy loss can be reduced; the middle part of the link arm 3 is hinged with the fuselage 1, so the two ends of the link arm 3 can swing up and down around the hinge point, and the slider 2 can also move with the The up and down swing of the link arm 3 generates up and down movement; the two ends of the output rod 4 are respectively hinged with the other end of the link arm 3 and one end of the toggle connector 8 . The power device 9 is a device that provides power for the toggle joint 8 to reciprocate back a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com