Preparation method and application of viscous anti-seepage material

An anti-seepage material and sticky technology, which is applied in the field of preparation of environmental protection materials, can solve problems such as irreparable, secondary environmental pollution, and increased leachate, and achieve no secondary pollution, secondary pollution, and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1 kg of fly ash, 30 kg of kaolin, 80 kg of bentonite, 2 kg of polyacrylic acid, 2 kg of polyacrylamide, 1 kg of polyacrylate and 2 kg of cetyltrimethylammonium chloride are used as raw materials, fully stirred and mixed After uniformity, the anti-seepage material will be obtained, with a density of 1.15g / cm 3 .

Embodiment 2

[0018] 2 kg of fly ash, 60 kg of kaolin, 40 kg of bentonite, 1 kg of polyacrylic acid, 2 kg of polyacrylate and 2 kg of cetyltrimethylammonium chloride are used as raw materials. Material with a density of 1.20g / cm 3 .

Embodiment 3

[0020] 5 kg of fly ash, 40 kg of kaolin, 50 kg of bentonite, 2 kg of polyacrylic acid, 2 kg of polyacrylamide and 2 kg of cetyltrimethylammonium chloride are used as raw materials, and the anti-seepage can be obtained after fully stirring and mixing uniformly. Material with a density of 1.18g / cm 3 .

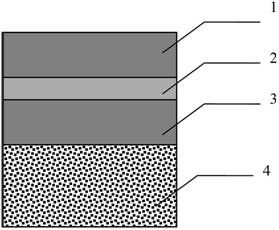

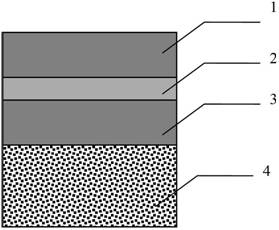

[0021] Use of viscous barrier materials such as figure 1 As shown, on the surface of the waste layer 4 to be treated in the landfill, a 10-20cm thick clay layer is laid, and the clay layer has a moisture content of 20-23%, and it is rolled and compacted three times back and forth to obtain the bottom compacted clay layer 3; Then lay the anti-seepage material 2 of the present invention with a thickness of 2-3cm, and finally lay a 10-20cm thick clay layer with a moisture content of 20-23%, and roll and compact it back and forth three times to obtain the top compacted clay layer 1. The permeability coefficient of this "sandwich" viscous anti-seepage system is 1×10 -10 cm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com