Cellulose nanocrystal suspension and preparation method thereof

A cellulose and nanocrystal technology, applied in the fields of polymers and nanomaterials, can solve the problems of preparation and research of cellulose nanocrystals, which are rarely reported, and achieve the effects of improved performance, uniform size and simple synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

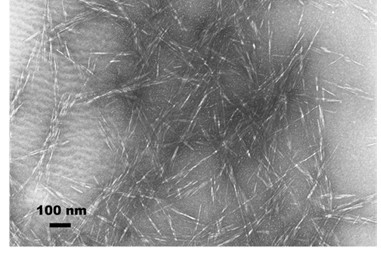

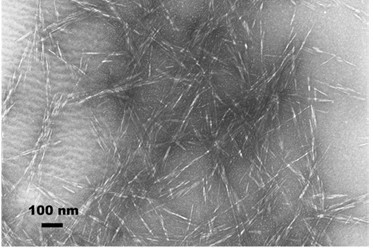

Image

Examples

Embodiment 1

[0025] Raw material pretreatment

[0026] Wet milling method: shred the cellulose pulp and add deionized water (prepared concentration 5%), soak for 12 hours, then pour it into a wet mill and grind it 5 times (gear spacing is 1 μm), 5 minutes each time.

Embodiment 2

[0028] Raw material pretreatment

[0029] Ultrasonic method: Add deionized water (prepared concentration: 3%) to the microcrystalline cellulose powder, soak for 2 hours, put it into an ultrasonic machine and ultrasonicate 5 times (ultrasonic frequency 1000Hz), 5 minutes each time.

Embodiment 3

[0031] Raw material pretreatment

[0032] Ball milling method: shred the cellulose pulp, add deionized water (prepared concentration 3%), soak for 12 hours, pour it into a ball mill and grind it 5 times (gear spacing is 2μm), 5 minutes each time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com