Seepage-proofing thermal-insulating coating and preparing method thereof

A technology of heat-insulating coatings and preservatives, applied in the direction of reflection/signal coatings, coatings, etc., which can solve the problems of high dosage of titanium dioxide and diatomite fillers, increased production costs of coatings, compactness, adhesion and anti-yellowing, etc. Insufficient performance and other problems, to achieve good anti-seepage and waterproof effect, good compactness, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

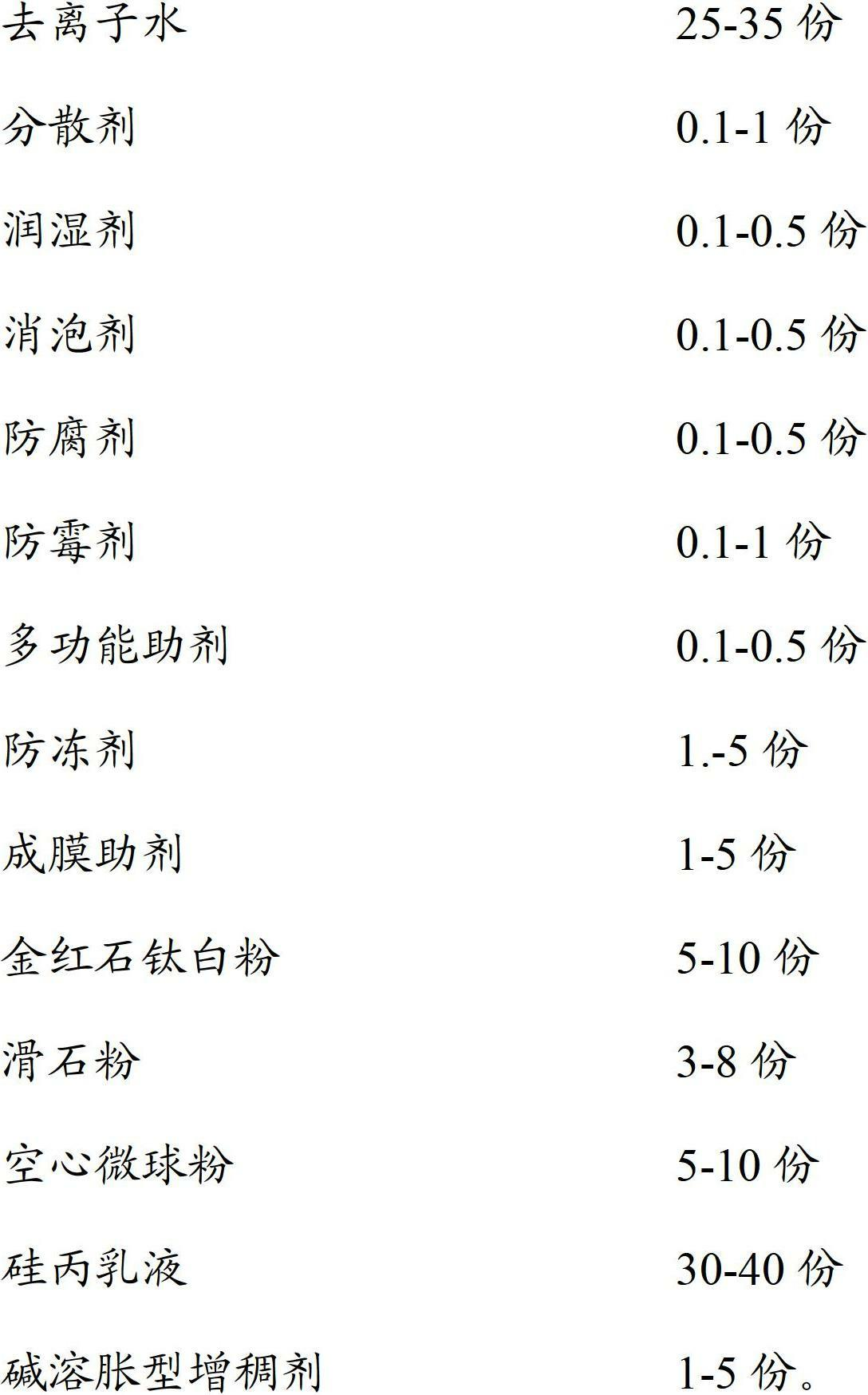

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the anti-seepage and heat-insulating coating of the present invention is prepared through the following steps:

[0027] (1) Add deionized water into the reaction tank with disperser and start the disperser;

[0028] (2) While stirring, add dispersants, wetting agents, defoamers, preservatives, antifungal agents, functional additives, antifreeze, and film-forming additives into the reaction tank in sequence, and stir to form a uniform Dispersions;

[0029] (3) Then increase the stirring speed, heat the reaction tank to 40-60°C, then add rutile titanium dioxide, talc powder, and hollow microsphere powder in sequence, and stir to disperse evenly;

[0030] (4) Finally, add silicon-acrylic emulsion and alkali-swellable thickener in sequence, stir for 10-20 minutes, and it is ready.

[0031] The dispersant mentioned in the following examples of the present invention is the SN-5040 dispersant produced by San Nopco Corporation of Japan; the wetting a...

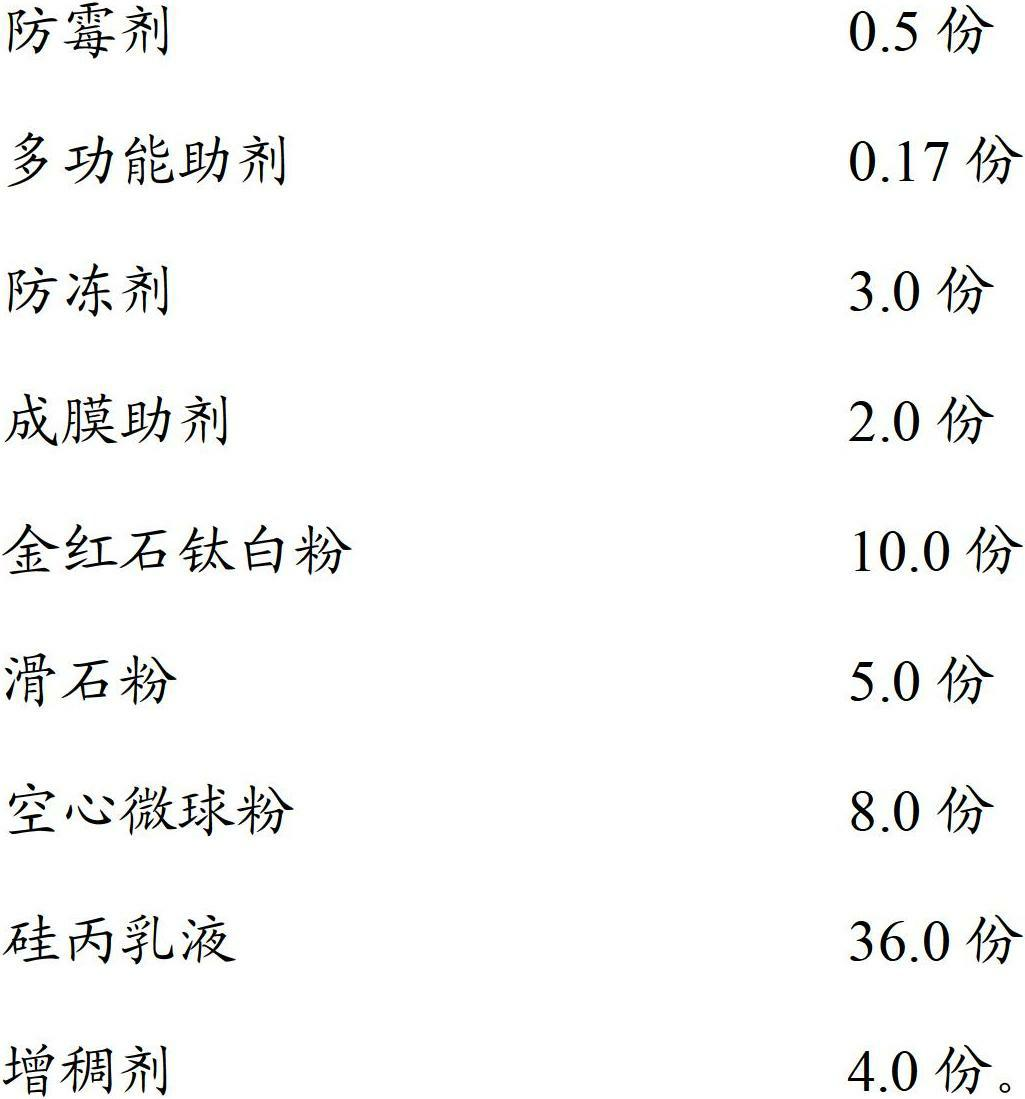

Embodiment 1

[0034] A kind of anti-seepage and heat-insulating coating is 30.15 parts by weight of deionized water, 0.5 part of dispersant, 0.18 part of wetting agent, 0.3 part of defoamer, 0.2 part of preservative, 0.5 part of antifungal agent, multi-functional 0.17 parts of additives, 3.0 parts of antifreeze, 2.0 parts of film-forming aids, 10.0 parts of rutile titanium dioxide, 5.0 parts of talcum powder, 8.0 parts of hollow microsphere powder, 36.0 parts of silicon-acrylic emulsion, 4.0 parts of thickener, prepared according to the above Composition made by method.

Embodiment 2

[0036] A kind of anti-seepage and heat-insulating coating is 25 parts by weight of deionized water, 0.1 part of dispersant, 0.5 part of wetting agent, 0.5 part of defoamer, 0.5 part of preservative, 0.1 part of antifungal agent, multifunctional 0.5 parts of additives, 5 parts of antifreeze, 1 part of film-forming aids, 10 parts of rutile titanium dioxide, 3 parts of talcum powder, 10 parts of hollow microsphere powder, 40 parts of silicon-acrylic emulsion, 5 parts of thickener, prepared according to the above Composition made by method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com