Production method of edible rice bran oil

A production method and technology of rice bran oil, which are applied in the directions of edible oil/fat, application, and fat production, can solve the problems of high operating cost, low product yield, unstable product quality, etc., and achieve the effect of improving food safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

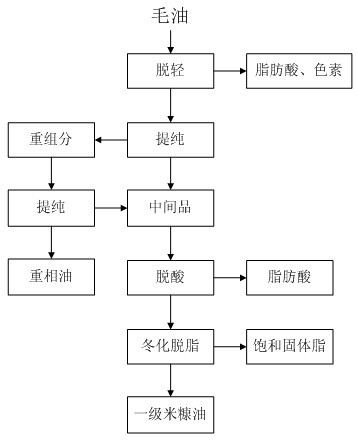

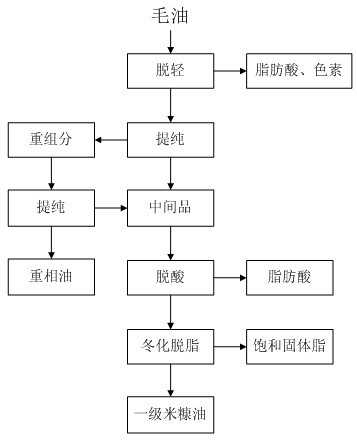

Image

Examples

Embodiment 1

[0031] 1) Deodorization, decolorization and deacidification

[0032] The raw material oil is grade 4 rice bran oil, which is transported to the preheater by the feed pump, heated to 200°C by the preheater, and then enters the separator. Under the high vacuum of 200Pa, the raw material oil is evenly distributed in the separator , and then heated to 250°C, reduce the pressure in the equipment to 150Pa, reduce the boiling point of the material, use the difference in boiling point of each substance in the raw material oil, heat the light components such as odorous substances, pigments and low-carbon fatty acids in the raw material oil To the boiling point, concentrate at the top of the separator, and after reaching a certain concentration, send it to the condenser to condense to 45°C and enter the light component receiving tank; the heavy component that has not evaporated is concentrated at the lower part of the separator, and sent to the heavy component receiving tank;

[0033] T...

Embodiment 2

[0050] 1) Deodorization, decolorization and deacidification

[0051] The raw material oil is grade 4 rice bran oil, which is transported to the preheater by the feed pump, heated to 250°C by the preheater, and then enters the separator. Under the high vacuum of 300Pa, the raw material oil is evenly distributed in the separator , and then heated to 280°C, reduce the pressure in the equipment to 200Pa, reduce the boiling point of the material, use the difference in boiling point of each substance in the raw material oil to heat the light components such as odorous substances, pigments and low-carbon fatty acids in the raw material oil When it reaches the boiling point, it is collected at the top of the separator. After reaching a certain concentration, it is sent to the condenser to condense to 55°C and enters the light component receiving tank; the heavy component that has not evaporated is concentrated at the lower part of the separator and sent to the heavy component receiving...

Embodiment 3

[0060] 1) Deodorization, decolorization and deacidification

[0061] The raw material oil is grade 4 rice bran oil, which is transported to the preheater by the feed pump, heated to 220°C by the preheater, and then enters the separator. Under the high vacuum of 250Pa, the raw material oil is evenly distributed in the separator , and then heated to 270°C, reduce the pressure in the equipment to 180Pa, lower the boiling point of the material, and use the difference in boiling point of each substance in the raw material oil to heat the light components such as odorous substances, pigments and low-carbon fatty acids in the raw material oil To the boiling point, concentrate at the top of the separator, and after reaching a certain concentration, send it to the condenser to condense to 50°C and enter the light component receiving tank; the heavy component that has not evaporated is concentrated at the lower part of the separator, and sent to the heavy component receiving tank;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com