Blurring image processing-based dynamic grain measuring device and method

A technology for blurring images and measuring devices, which is applied to devices for three-dimensional position and motion speed information to obtain particle size and size, which can solve the problems of high system cost, short exposure time, and difficult adjustment, avoiding system synchronization and simplifying measurement. System and data processing process, the effect of reducing system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

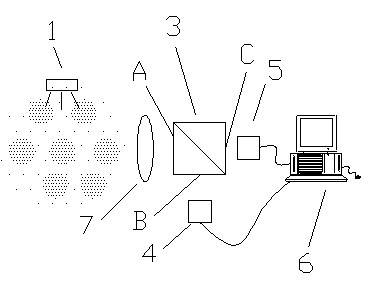

[0045] Such as figure 2 As shown, the lens (2) adopts the telecentric lens (7). Within the range of the depth of field of the telecentric lens, the image size of the object does not change with the change of the position, so that the particle size can be obtained. The measurement steps are the same as in Example 1.

Embodiment 3

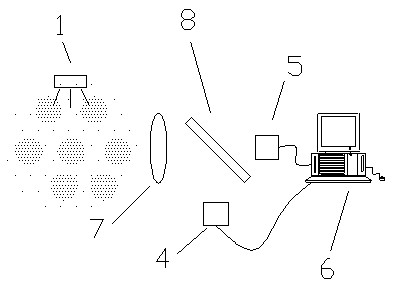

[0047] Such as image 3 As shown, the dichroic prism (3) in the embodiment 1 can also be replaced by a plane beam splitter (8), and this plane beam splitter (8) is formed by coating a dichroic film on an optical flat plate. The measurement steps are the same as in Example 1.

[0048] In the above three embodiments, both the first image sensor and the second image sensor use CCD or CMOS devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com