Micro-strip scoop-type feed slit surface wave excitation antenna

A technology for exciting antennas and feeding slots, which is applied to leaky waveguide antennas, circuits, and structural forms of radiation elements, etc., can solve problems such as increased loss, difficulty in use, and difficulty in ensuring dimensional processing accuracy, and achieve simplified design, large front-to-back ratio, small structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

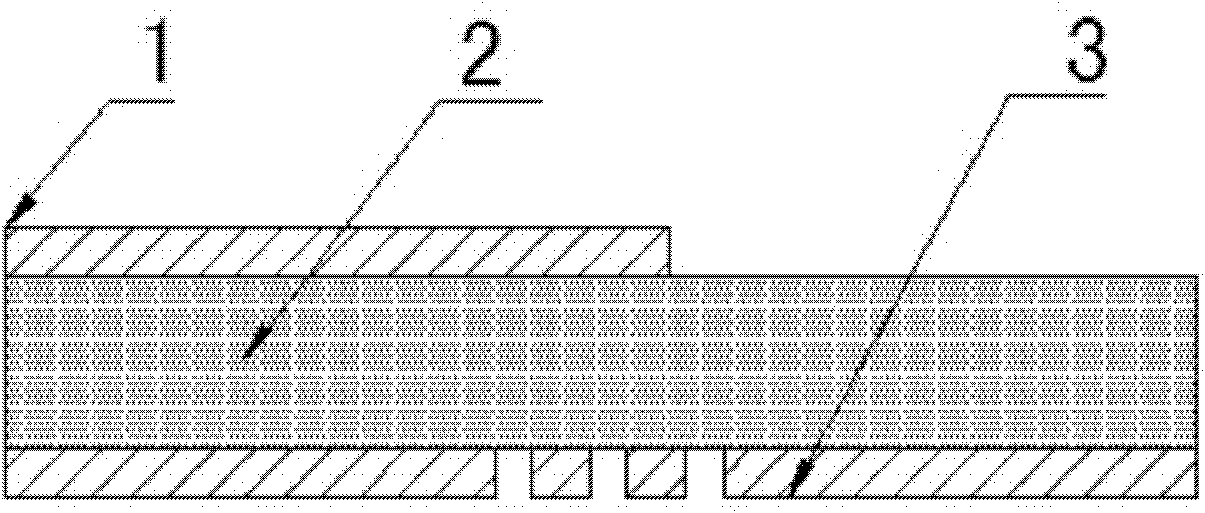

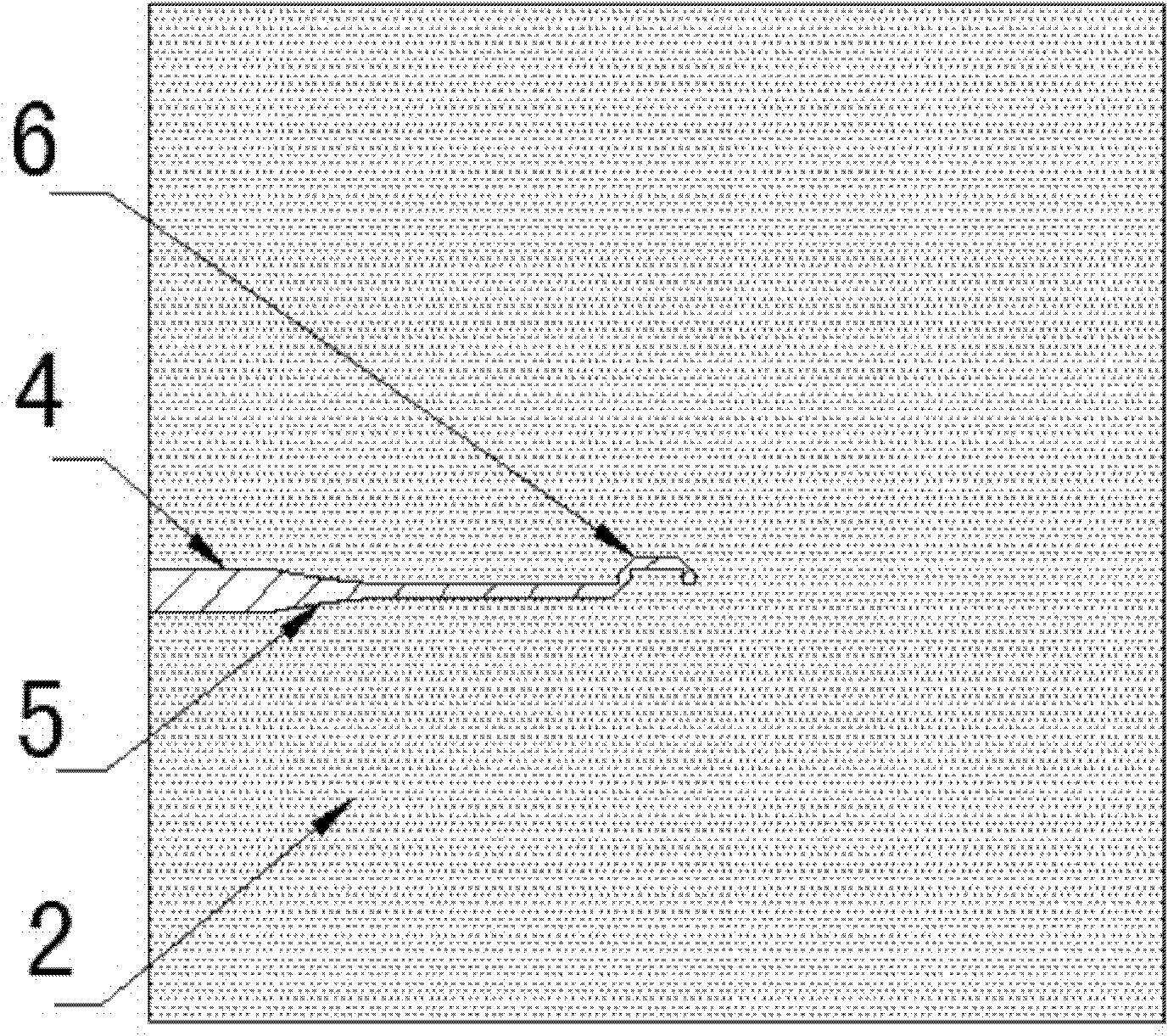

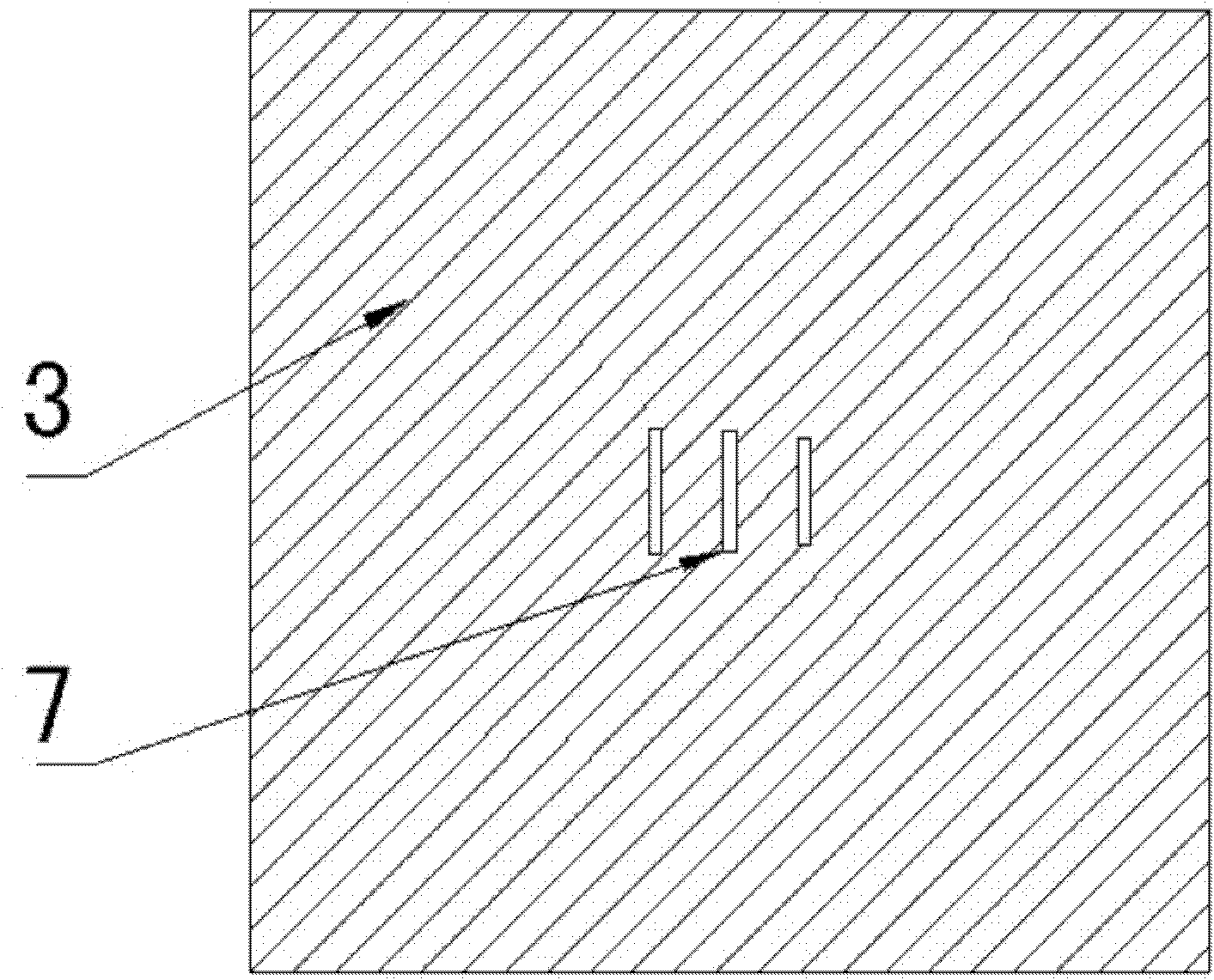

[0023] The overall structure of the surface wave excitation antenna is as follows Figure 1~3 As shown, the antenna consists of a feeding unit and a radiating unit.

[0024] The microstrip spoon-feed slot surface wave excitation antenna is divided into three layers, the upper and lower layers are metal layers 1 and 3, the middle is the dielectric layer 2, the upper metal layer 1 is the microstrip feeding structure of the antenna, and the microstrip feeding unit It consists of a 50Ω first microstrip line 4 connected to a spoon-shaped microstrip 6 through an exponential gradient microstrip structure 5. The signal is excited and starts from the 50Ω first microstrip line 4. Impedance matching is realized through an exponential gradient microstrip structure 5. The spoon-shaped The microstrip 6 feeds power to the radiating unit 7 of the rear metal layer, wherein the radiating unit 7 is provided with three Yagi slits in the grounded metal layer 3 to realize directional radiation.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com