Use of specific composite materials as extinguishing material for electric arcing in electric apparatuses

A composite material and electrical equipment technology, applied in electrical components, circuits, electrical switches, etc., can solve the problems of complex arc extinguishing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

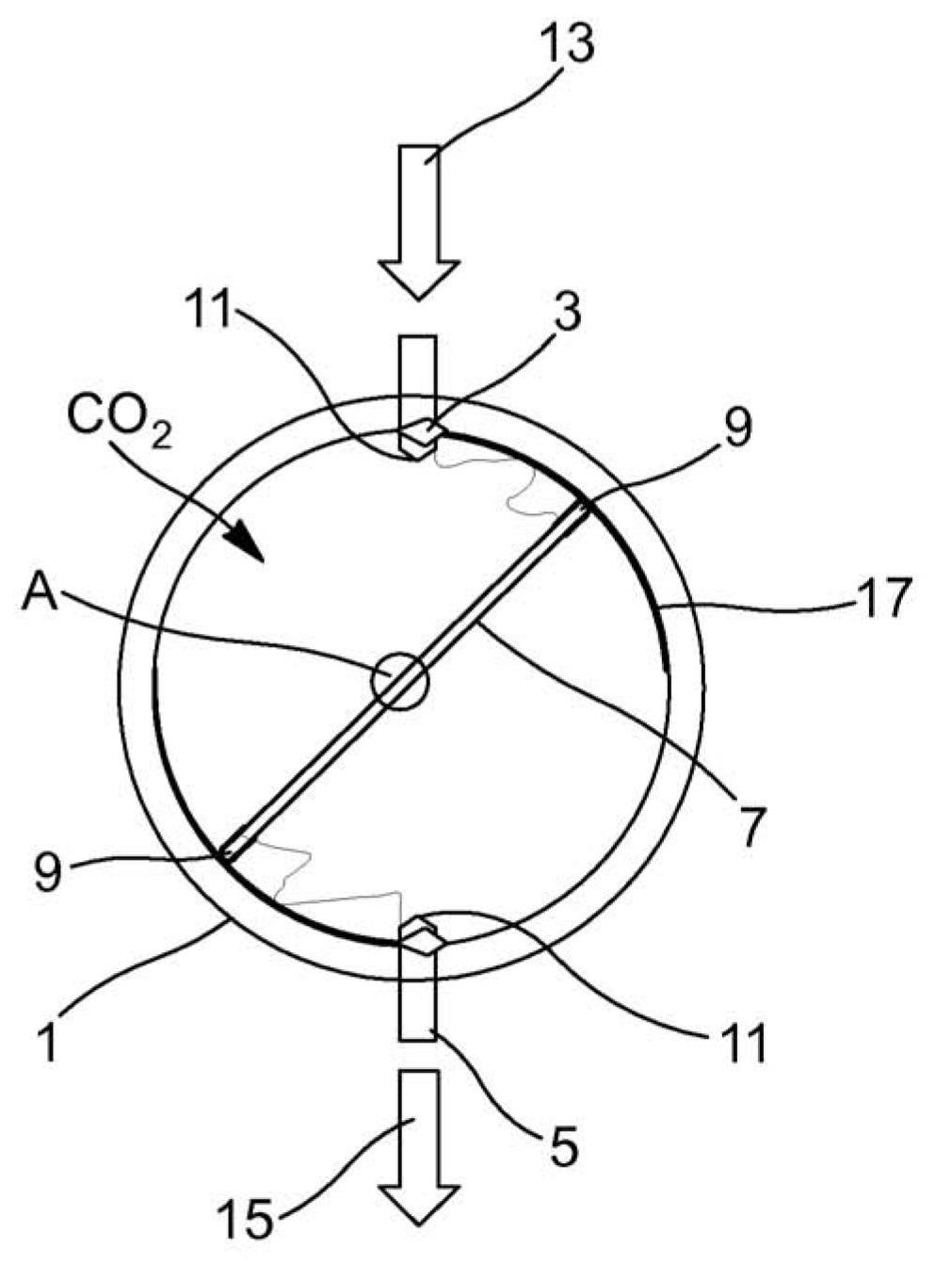

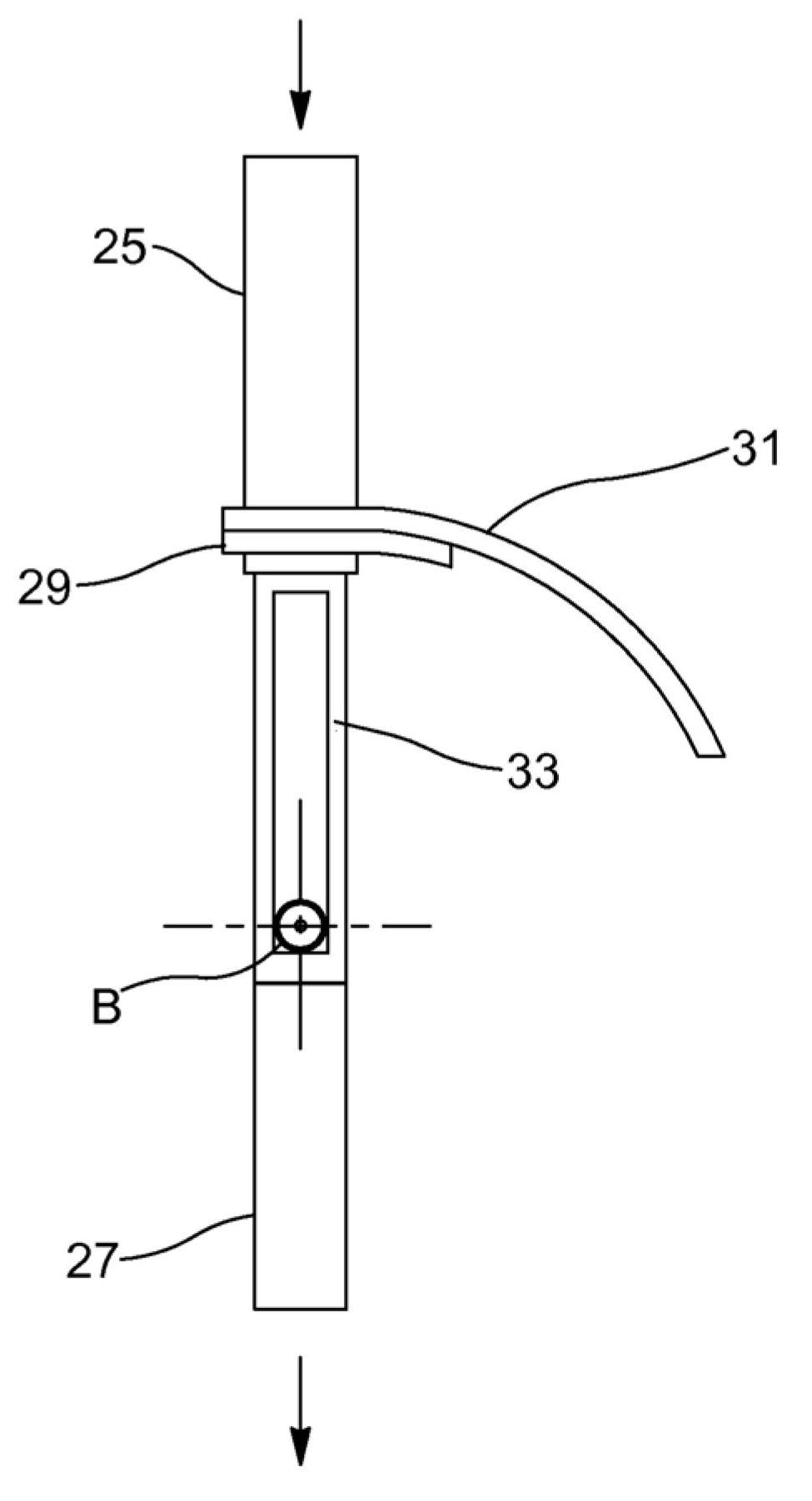

[0052] figure 1 An insulating chamber 1 is shown with two diametrically opposed stationary contacts 3, 5 at its edges and containing a moving contact 7 mounted concentrically with the insulating chamber 1 about an axis A in the center.

[0053] The moving contact 7 is in the form of a rod, its length is slightly shorter than the inner diameter of the insulating cavity 1, and has an end 9 that can be in contact with the ends 11 of the static contacts 3, 5 at the same time, and the static contacts 3, 5 penetrate into the interior of the insulating cavity 1 .

[0054] The input current is indicated by a first arrow 13 at the first fixed contact 3 ; the output current is indicated by a second arrow 15 away from the other fixed contact 5 diametrically opposite to the first fixed contact.

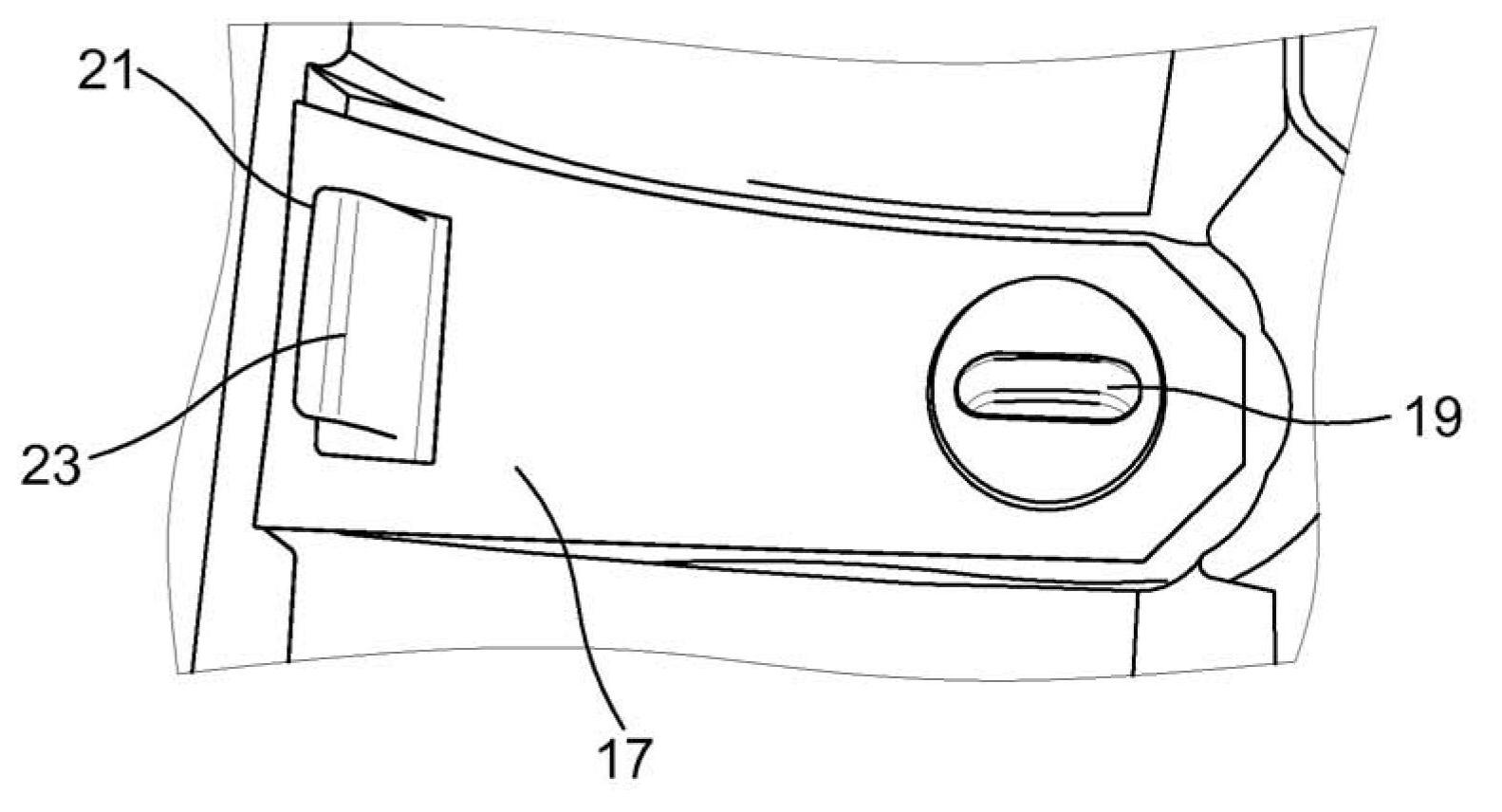

[0055] washer( figure 1 not shown in ) around the end 11 of each static contact 3,5; it is formed from a composite material according to the invention, ie comprising a polymer matrix (advantage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com