Wear-resistant communication optical cable jacket pipe special material and preparation method thereof

A technology for communication optical cables and sheath tubes, which is applied in the direction of plastic/resin/wax insulators, organic insulators, rubber insulators, etc., which can solve problems such as frictional damage, poor wear resistance, and impact on optical fiber transmission, and achieve wear-resistant and wear-resistant properties Strong, guarantee the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

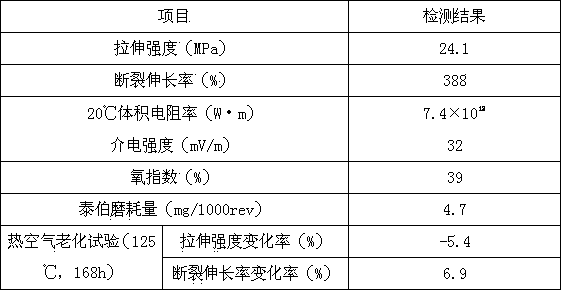

Examples

Embodiment

[0012] A special material for wear-resistant communication optical cable sheath tube, made of the following weight (kg) raw materials: ultra-high molecular weight polyethylene 42, polyoxymethylene 26, tantalum diselenide 13, zirconium corundum powder 11, vaseline 6, Songhua Stone powder 12, perfluoropolyether 5, lanthanum fluoride 4, chlorinated paraffin 7, acetyl tributyl citrate 16, high wear-resistant carbon black N660 18, zinc oxide whisker 6, butadiene rubber 23, dibutyl sulfide Urea 2.5, basic lead silicate 4.5, 2-phenylindole 4, oxidized polyethylene wax 5, octadecyl dodecyl thiodipropionate 1.5, tolyl diphenyl phosphate 6, auxiliary 3.5 ;

[0013] The preparation method of the auxiliary agent is as follows: a. Take the following raw materials in parts by weight: calcium zirconate 12, methylenebis(2,4-di-tert-butylphenoxy)aluminum phosphate 4.5, titanium oxalate 3.5, rectorite 10. Methyl 3,5-di-tert-butyl-4-hydroxybenzoate 2.5, dodecyl glucoside 1.5, N-aminoethylpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com