Slurry bed reactor

A reactor and slurry bed technology, applied in the field of Fischer-Tropsch synthesis, can solve the problems of affecting the extraction of clear liquid, slowing down the degree of thickening of catalyst filter cake, reducing the effective utilization of filter filtration area, etc. The effect of improving the effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings and examples.

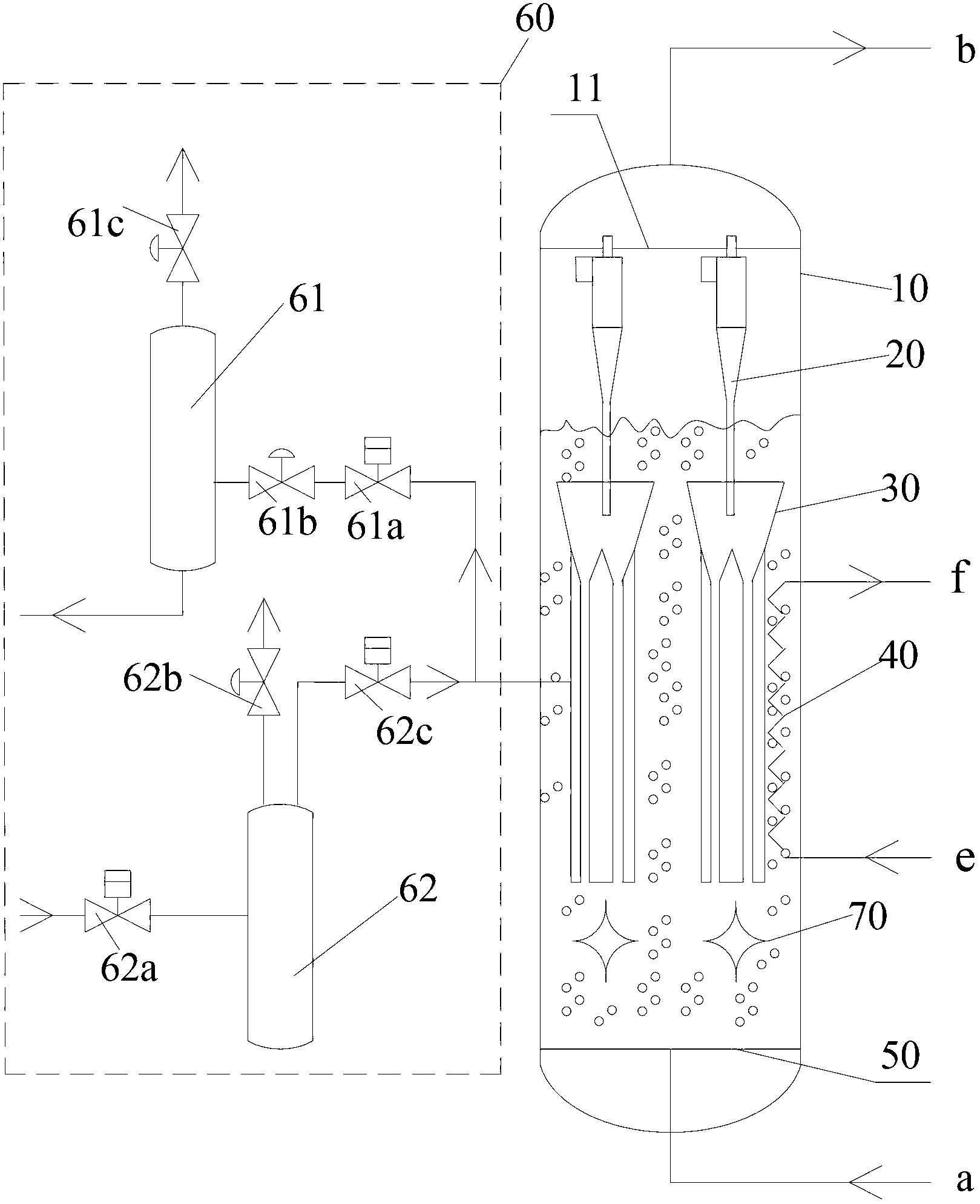

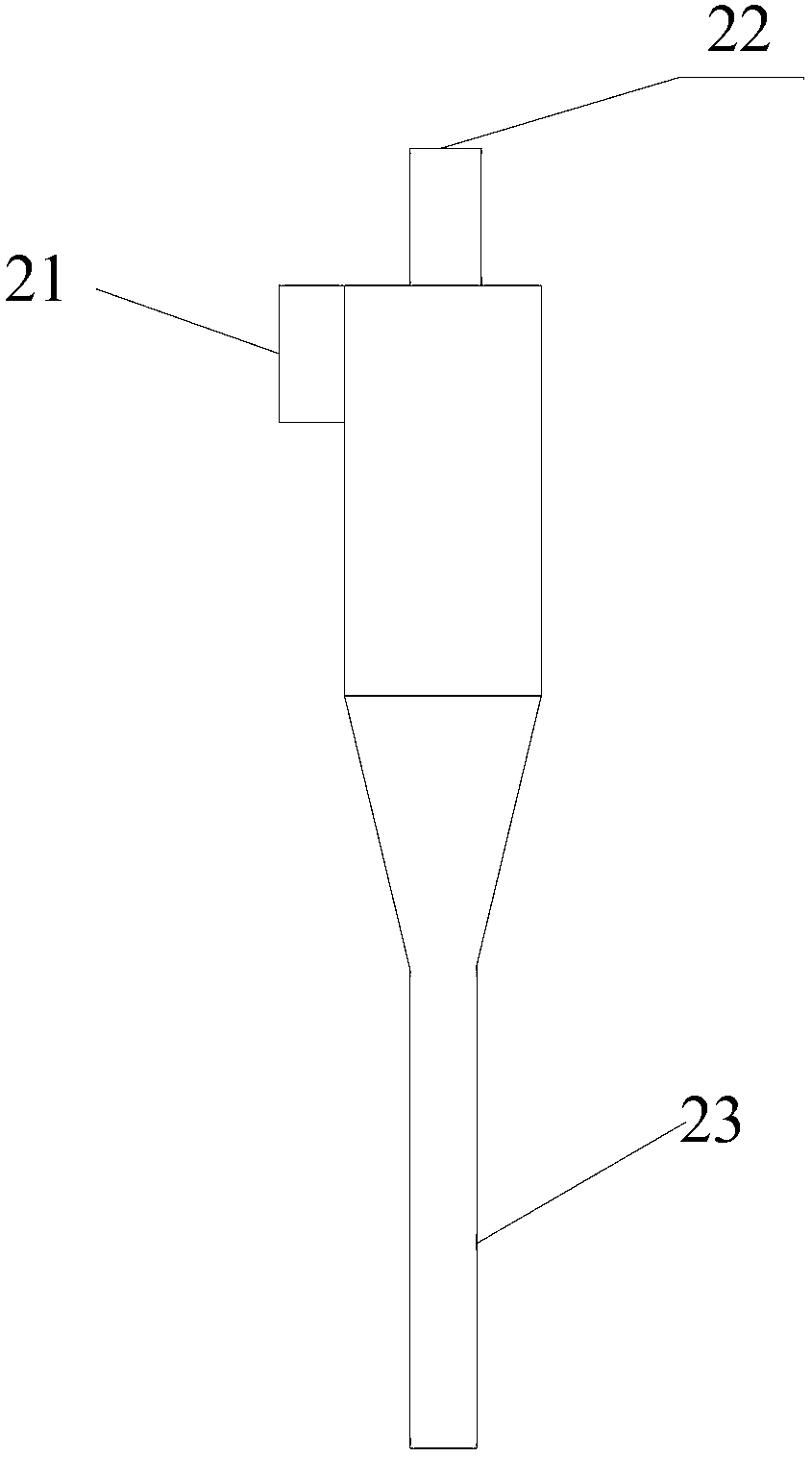

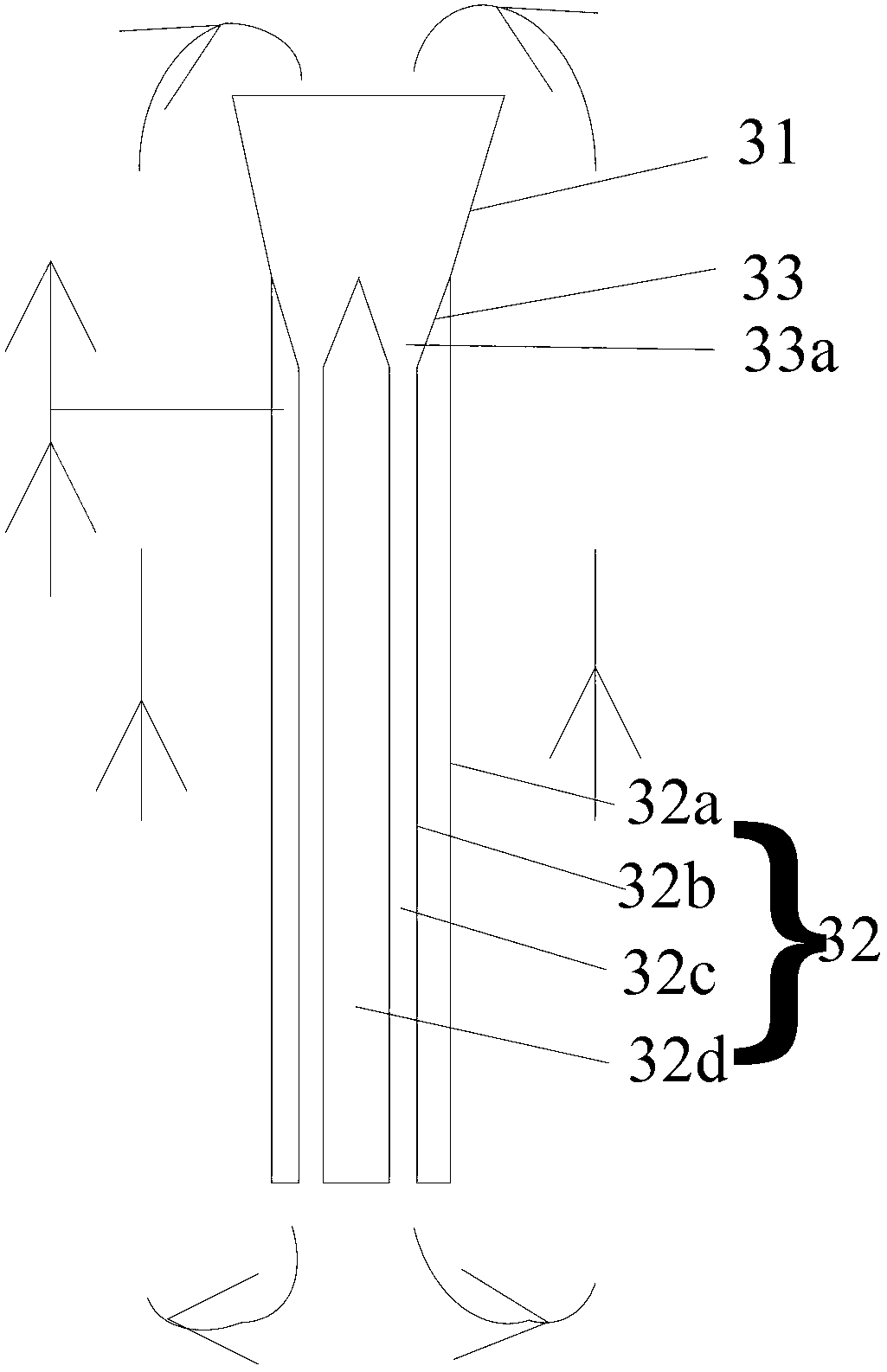

[0038] like figure 1As shown, the slurry bed reactor according to the present invention includes: a reactor cylinder 10, the bottom of the inner cavity of the reactor cylinder 10 is provided with a gas introduction device, and the inner cavity of the reactor cylinder 10 is provided with a Fischer-Tropsch Wax and catalyst separation device 30; the outside of reactor shell 10 is provided with and communicates with Fischer-Tropsch wax and catalyst separation device 30 to extract Fischer-Tropsch wax and Fischer-Tropsch wax and catalyst separation device 30 backwash Fischer-Tropsch wax extraction and reverse Blowing system 60 ; a gas-liquid separation device located above the Fischer-Tropsch wax and catalyst separation device 30 is also provided in the inner chamber of the reactor cylinder 10 . By installing a gas-liquid separation device on the top of the Fis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com