Production facility of normal temperature solidified fluorine-contained coating

A technology for fluorine-containing coatings and production equipment, applied in coatings, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as inconvenient operation, impact on product quality, and poor controllability, and achieve short curing time. , Excellent stain resistance and self-cleaning performance, good reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

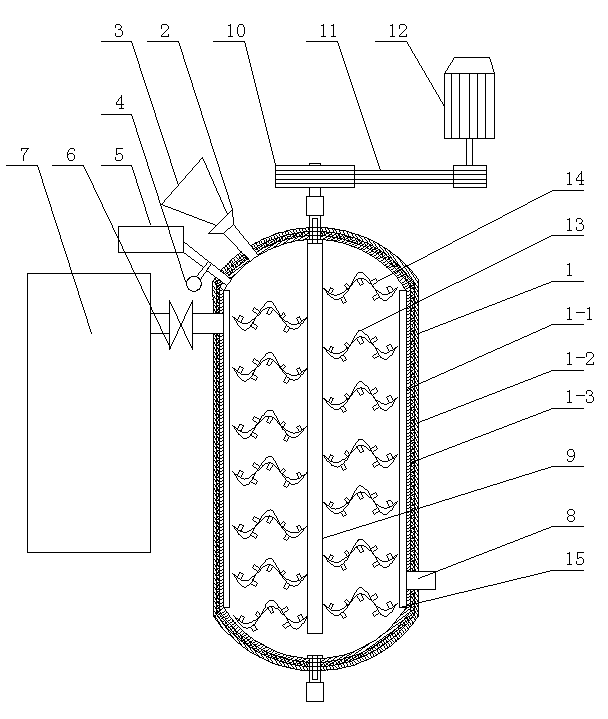

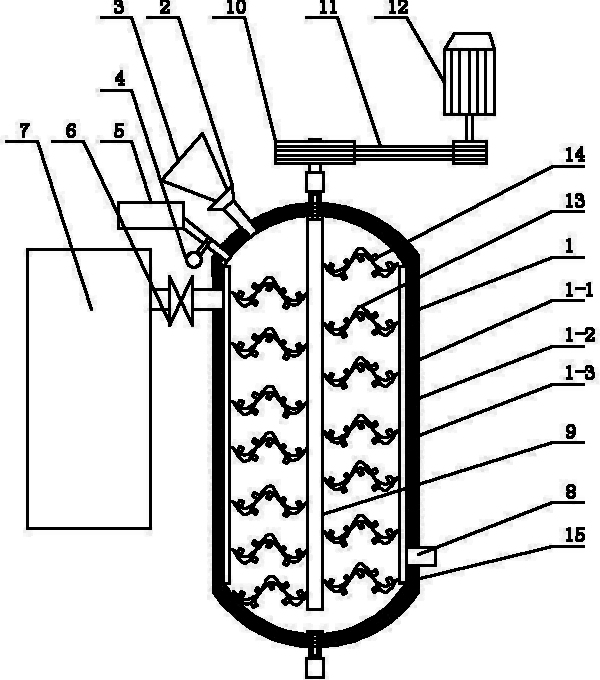

[0019] as attached figure 1 Shown: the production equipment of normal temperature curing fluorine-containing coatings of the present invention comprises a kettle body 1, the kettle body is connected with a feeder 3 through a metering device 2, and the kettle body is connected with a negative pressure suction through a negative pressure gauge 4 device 5, the kettle body is connected to the compressed nitrogen cylinder 7 through the solenoid valve 6, and the bottom of the kettle body has a discharge port 8, and the central axis position of the kettle body is installed with a stirring shaft 9, and on the stirring shaft A belt pulley 10 is installed, and the belt pulley is connected to a drive motor 12 through a belt 11. A group of blades 13 are installed on the stirring shaft, and a group of support pieces 14 are installed on each of the blades.

Embodiment 2

[0021] In the production equipment for curing fluorine-containing coatings at room temperature, the blades are helical, and the support pieces are evenly installed on the blades along the direction of the helical curve of the blades.

Embodiment 3

[0023] In the production equipment for curing fluorine-containing coatings at room temperature, the kettle body includes an inner wall 1-1 and an outer wall 1-2, and an insulating layer 1-3 is provided between the inner wall and the outer wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com