Mesoporous silicon dioxide microsphere-loaded zero-valent iron nanoparticle (SiO2@ FeOOH@ Fe) and preparation method and application thereof

A technology of mesoporous silica and nano-zero valent iron is applied in chemical instruments and methods, restoration of polluted soil, water pollutants, etc. Good fluidity and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

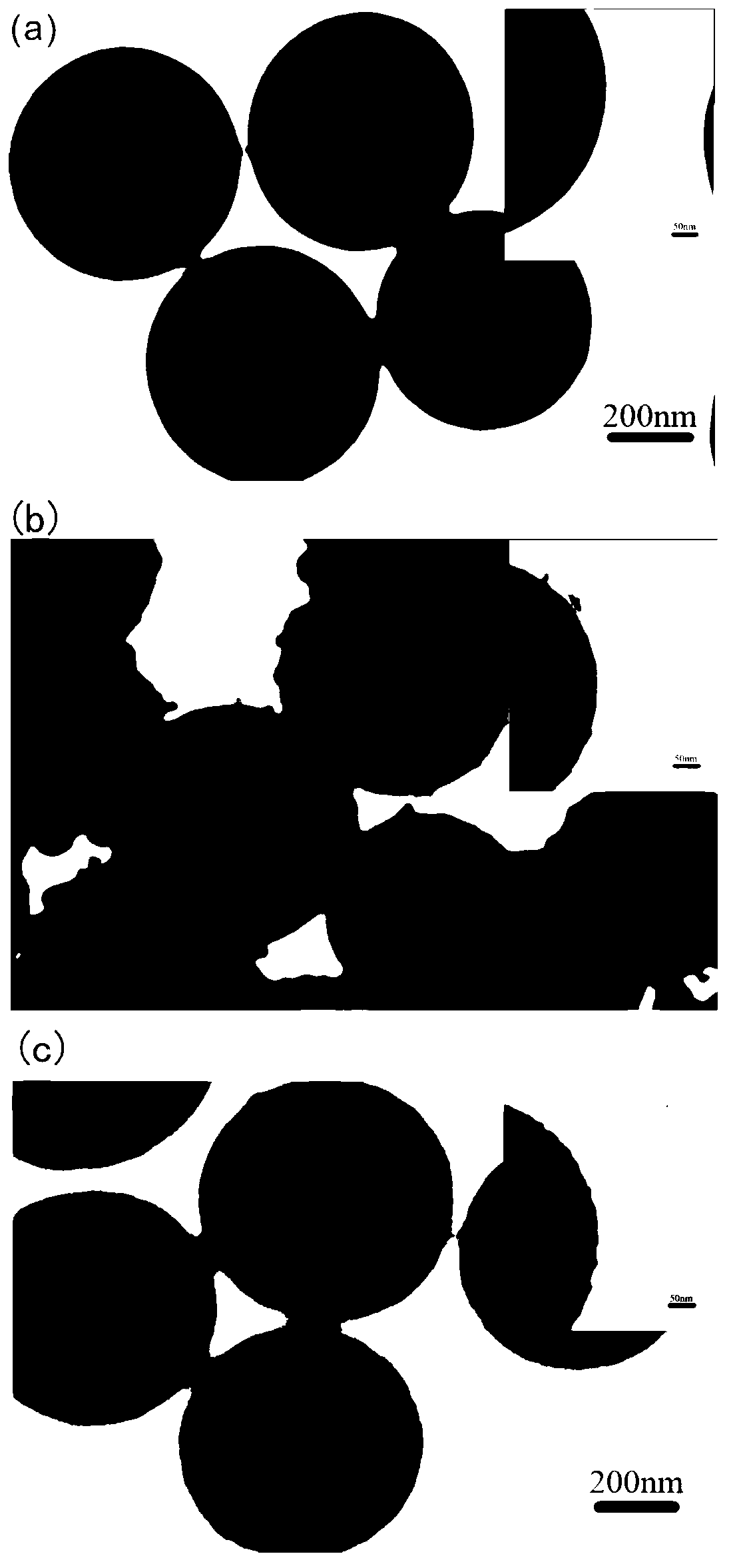

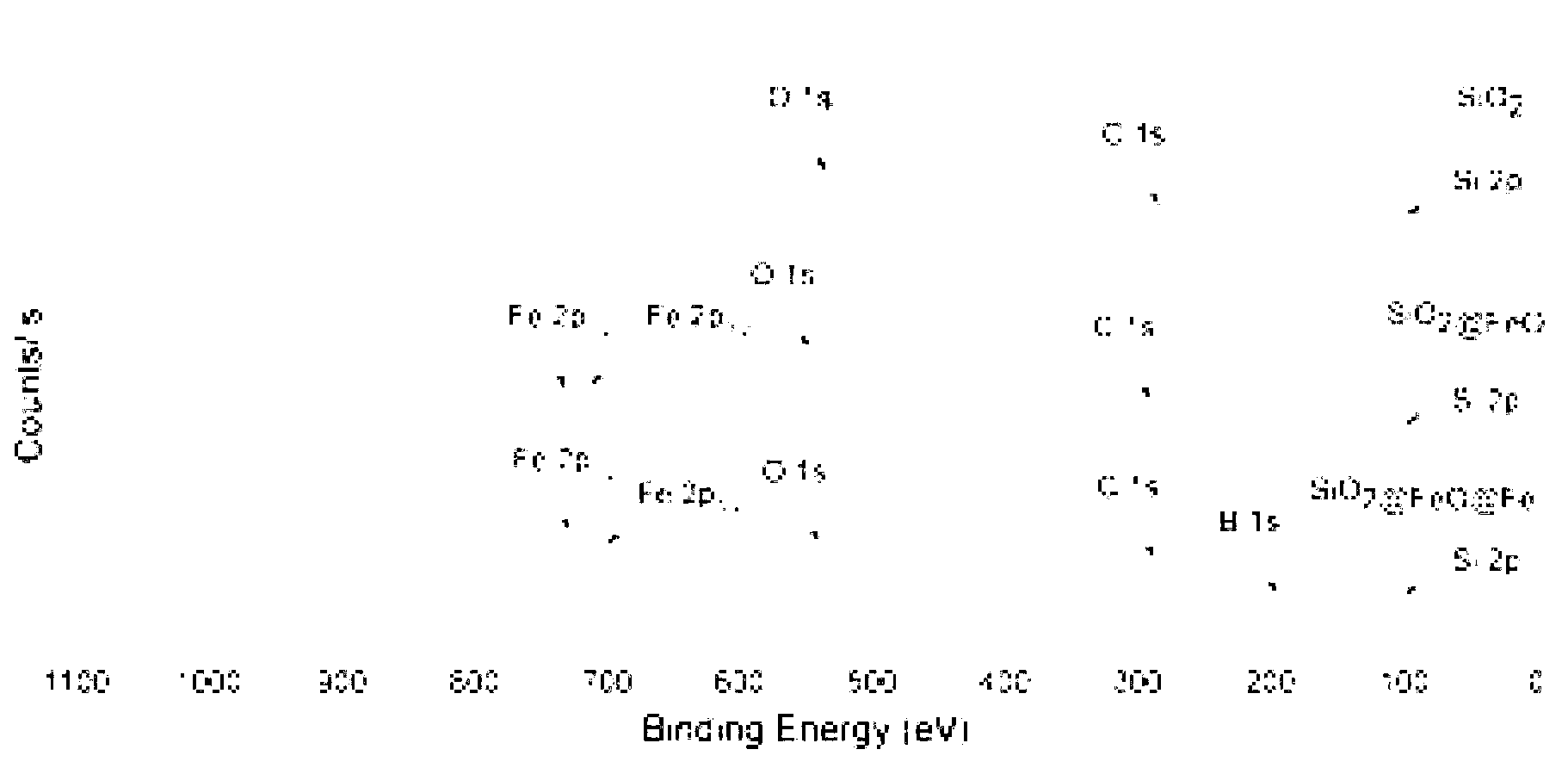

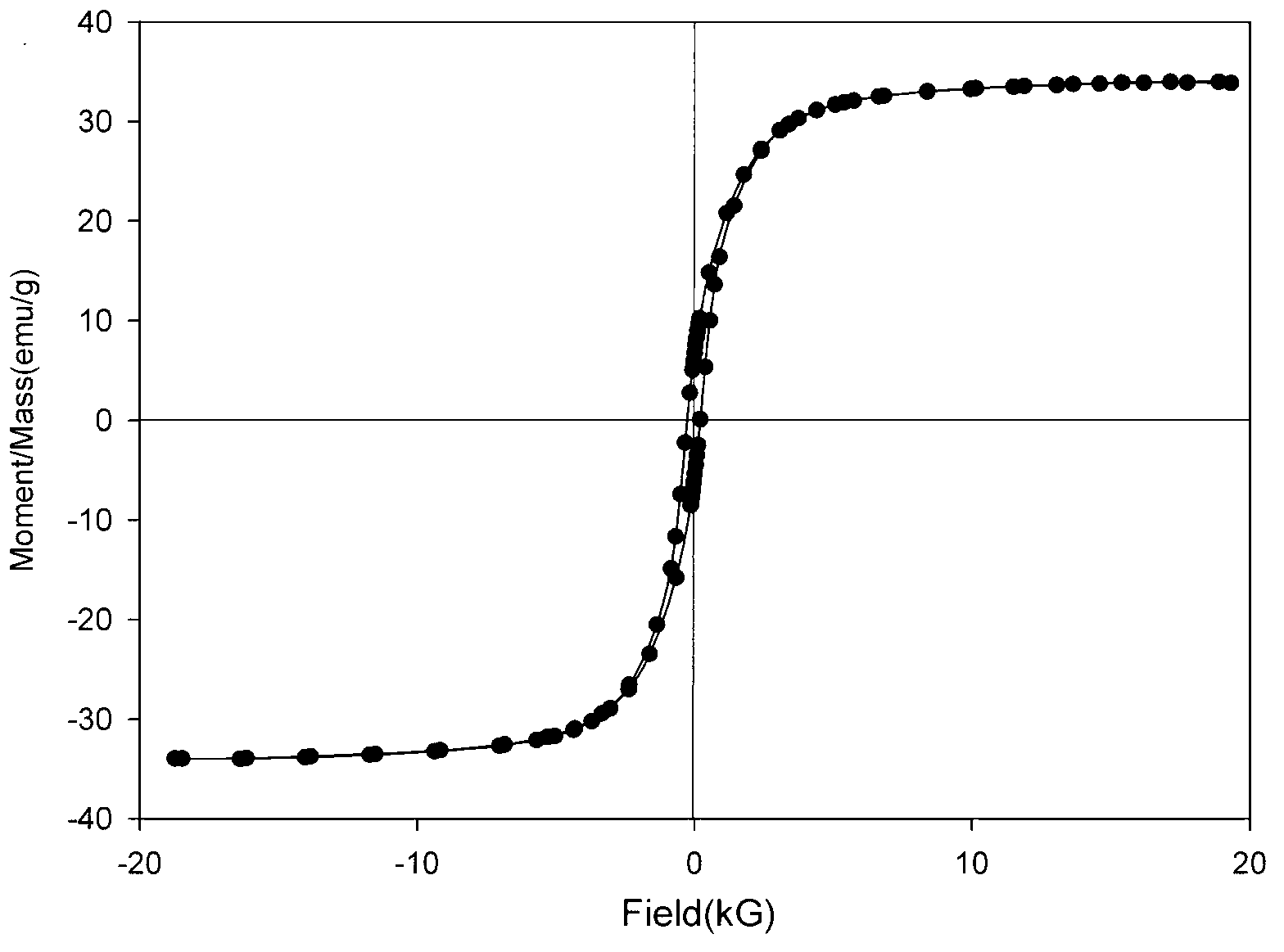

[0030] SiO 2 Preparation method 1 of FeOOHFe:

[0031] (1) Synthesis of mesoporous silica microspheres

[0032] Dissolve 0.22g of dodecylamine in 50ml of ethanol aqueous solution ([EtOH]=50 vol%), stir and mix evenly, then slowly add 1.1g of ethyl orthosilicate dropwise, continue to stir for 30s, and stand at room temperature 3 hours; centrifuge the obtained product (3000rpm, centrifuge for 5min), wash with water and ethanol for 3 times respectively, and dry in a vacuum oven at 60°C for 6 hours; then place the dried product in a muffle furnace , the temperature was raised to 600° C. at a rate of 1° C. / min, and kept for 4 hours to obtain mesoporous silica microspheres.

[0033] (2) Surface modification of mesoporous silica microspheres

[0034] Prepare 50ml of an aqueous solution containing 0.5g of polyethylene glycol, and add 0.6g of FeSO4 7H2O to the solution, sonicate for 10 minutes to make it dissolve evenly; cook the mesoporous silica microspheres in a water bath at 60°...

Embodiment 2

[0039] SiO 2 Preparation method 2 of FeOOHFe:

[0040] (1) Synthesis of mesoporous silica microspheres

[0041] Dissolve 0.25g of dodecylamine in 50ml of ethanol aqueous solution ([EtOH]=50 vol%), stir and mix evenly, then slowly add 1.2g of ethyl orthosilicate dropwise, continue to stir for 30s, and stand at room temperature 4 hours; the obtained product was centrifuged (3000rpm, centrifuged for 5min), washed with water and ethanol three times respectively, and dried in a vacuum oven at 70°C for 5 hours; then the dried product was placed in a muffle furnace for 5 The ramp rate of °C / min was increased to 600 °C and maintained for 5 hours.

[0042] (2) Surface modification of mesoporous silica microspheres

[0043] Prepare 50ml of an aqueous solution containing 1g of polyethylene glycol, and add 1.5g of FeSO to the solution 4 ·7H 2 After O, sonicate for 20 minutes to make it dissolve evenly; then immerse 0.6g of mesoporous silica microspheres in the above solution, take it...

Embodiment 3

[0048] SiO 2 Preparation method 3 of FeOOHFe:

[0049] (1) Synthesis of mesoporous silica microspheres

[0050] Dissolve 0.28g of dodecylamine in 50ml of ethanol aqueous solution ([EtOH]=50 vol%), stir and mix evenly, then slowly add 1.2g of ethyl orthosilicate dropwise, continue to stir for 60s, and stand at room temperature 5 hours; the obtained product was centrifuged (3000rpm, centrifuged for 5 minutes), washed with water and ethanol for 3 times, and dried in a vacuum oven at 80°C for 4 hours; then the dried product was placed in a muffle furnace, The temperature was raised to 600°C at a rate of 10°C / min and kept for 5 hours.

[0051] (2) Surface modification of mesoporous silica microspheres

[0052] Prepare 50ml of an aqueous solution containing 1g of polyethylene glycol, and add 1.2g of FeSO to the solution 4 ·7H 2 After O, sonicate for 30 minutes to make it dissolve evenly; then immerse 0.6g of mesoporous silica microspheres in the above solution, take it out afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Remanence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com