Preparation method of recycled aggregate aerated concrete block

A technology of aerated concrete and recycled aggregate, which is applied in the field of building materials and building materials raw materials, can solve the problems of wasting natural resources, consuming large coal resources, and increasing additional costs, saving labor, time, labor, and additional costs, protecting natural resources, The effect of eliminating additional costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

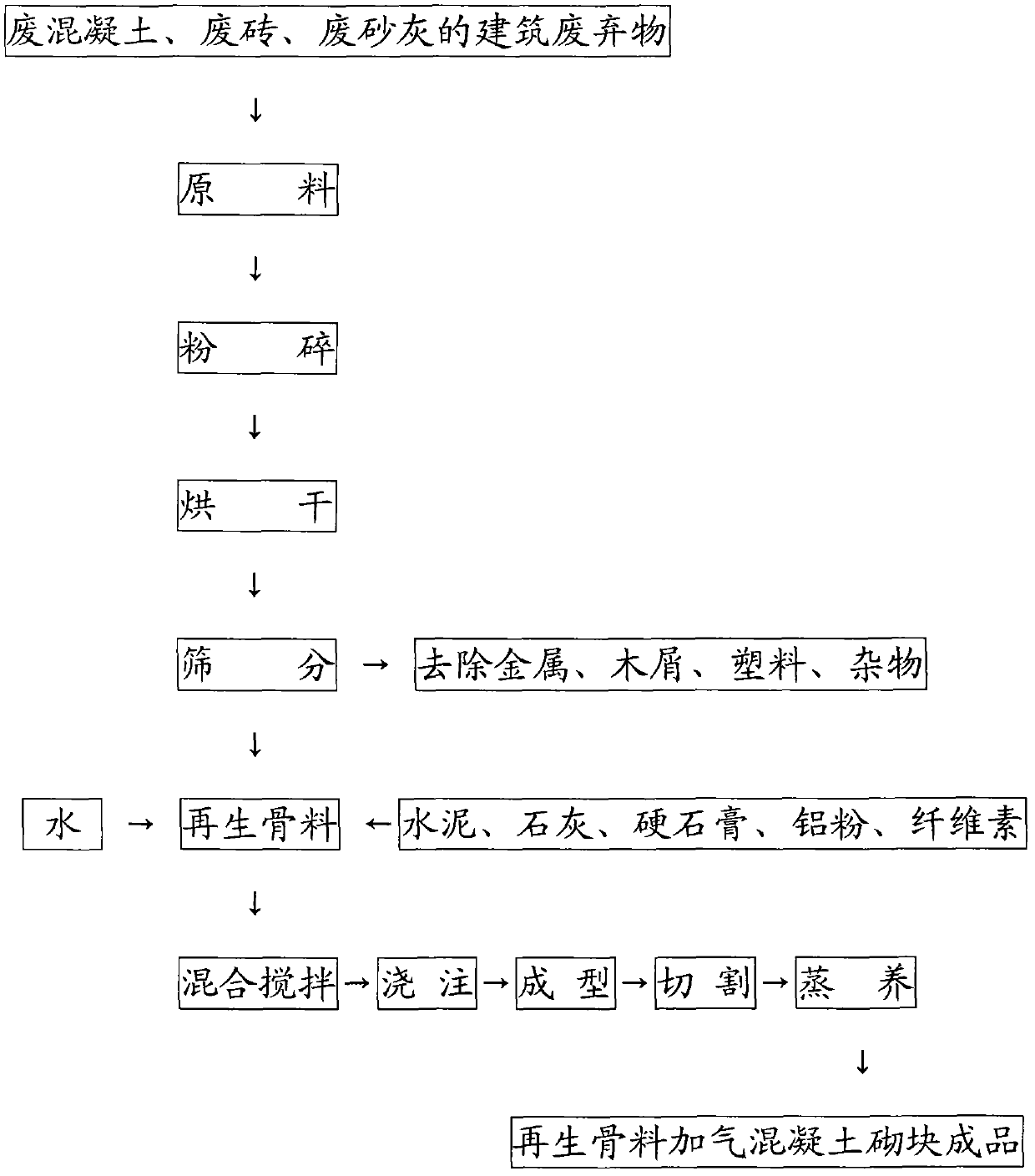

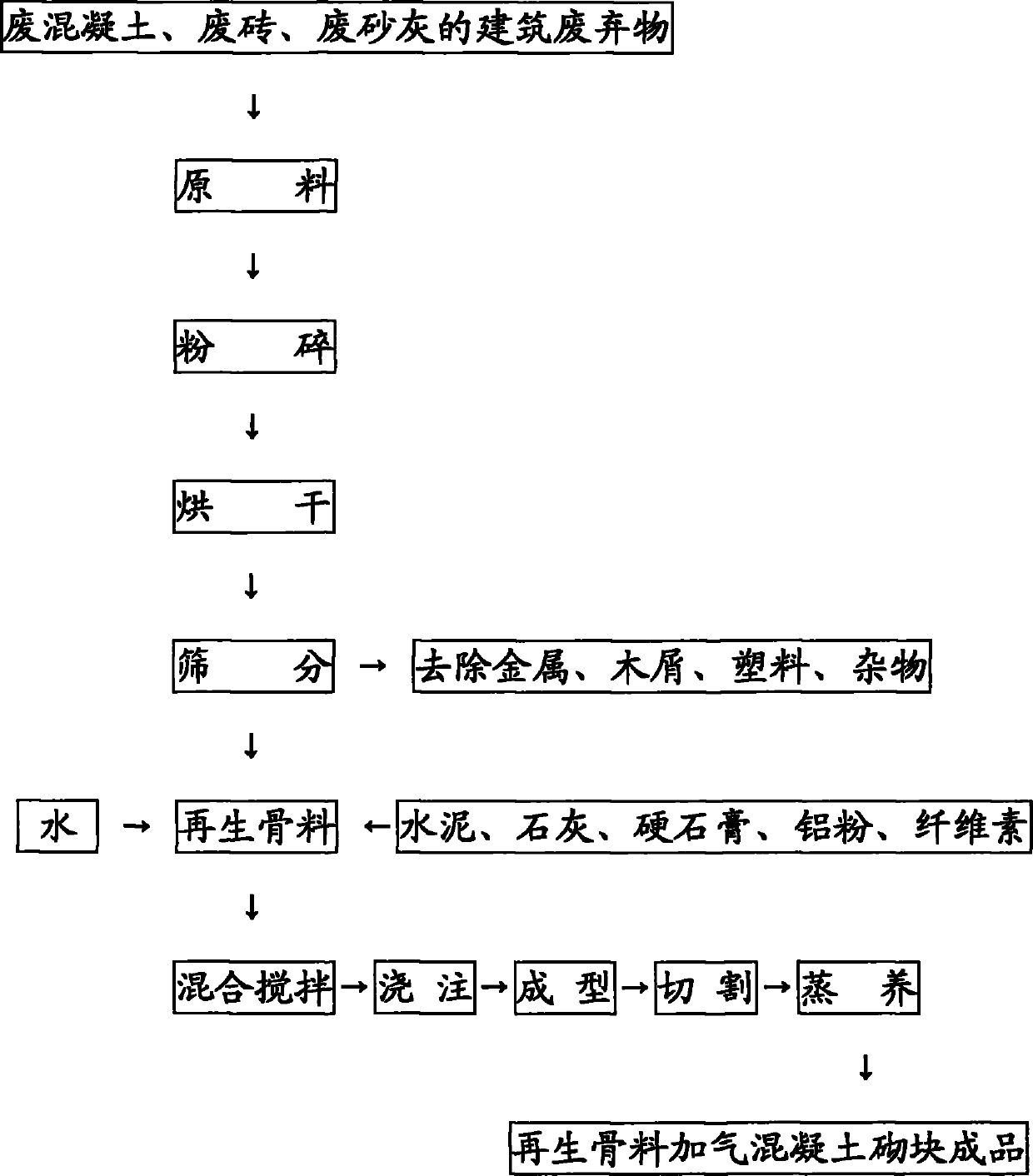

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0022] A preparation method of recycled aggregate aerated concrete block:

[0023] ①. Preparation of recycled aggregate: Use waste concrete, waste bricks, and waste sand and ash construction waste less than 690mm in size as raw materials, determine the quantity according to needs, and then sieve after crushing and drying with a moisture content of less than or equal to 0.5%. In the process, magnets are used to remove metal, and wood chips, plastics and sundries are removed in a manner of specific gravity, so as to prepare recycled aggregates with a particle size of 0.3-2.36mm and store them for later use;

[0024] ②. Preparation of recycled aggregate concrete block: 692 kg of recycled aggregate, 138 kg of cement, 138 kg of lime, 30 kg of anhydrite, 0.4 kg of aluminum powder, 0.5 kg of cellulose, and 220 kg of water were mixed a...

specific Embodiment approach 2

[0026] Carry out according to specific embodiment 1, just based on the implementation quantity of specific embodiment 1, reduce 1, 2, 5, 8, 10, 15, 20, 25, 30, 35, 40, 45, 50 times and carry out implementation, and on this basis, respectively enlarged 1, 2, 5, 8, 10, 15, 20, 25, 30, 35, 40, 45, and 50 times for implementation; thus obtained principle test, small-scale test, experimental Laboratory test, expanded test, medium-scale test, large-scale test, productive test of various scales of repeated tests, all obtained good results expected, so that the present invention has a solid foundation from principle to implementation, creating a new era for practical application Good conditions have laid a solid foundation for widespread promotion and application.

[0027] After the production of the present invention, a trial assessment was carried out. During the trial assessment, experts in the industry agreed that: the development of recycled aggregates was successful, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com