Preparation method of aqueous polyurethane emulsion for synthetic leather

A technology of water-based polyurethane and synthetic leather, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of reducing hydrolysis resistance and achieve the effect of improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

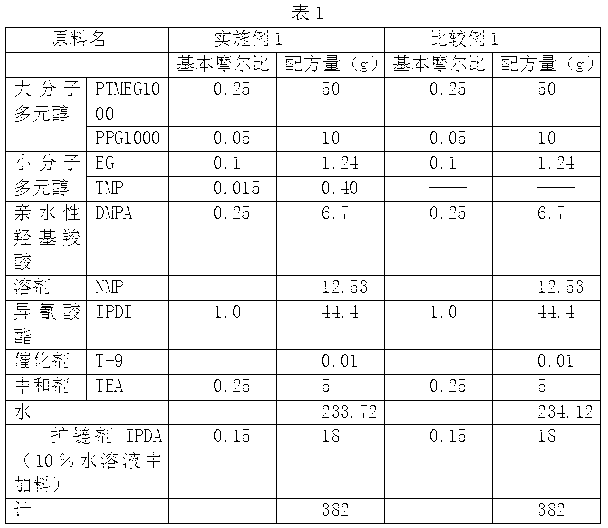

Embodiment 1

[0025] Add 50g PTMEG1000, 10g PPG1000, 1.24g EG, 0.4g TMP, 6.7g DMPA, 12.53g NMP into the reactor equipped with a stirrer, thermometer, and reflux condenser, heat up to 80°C, heat to dissolve for 30 minutes, then add 44.4g IPDI, 0.01 g of T-9, reacted at 80° C. for 5 hours under stirring to obtain a prepolymer. Cool down to 60°C, add 5g of triethylamine to neutralize the prepolymer into salt, keep stirring for 20 minutes, then add 233.72g of deionized water under high-speed shear, add water to emulsify and disperse for 30 minutes, and then add 18g of Dilute the amine for chain extension with 10% water and stir for 30 minutes after the addition to obtain an emulsion.

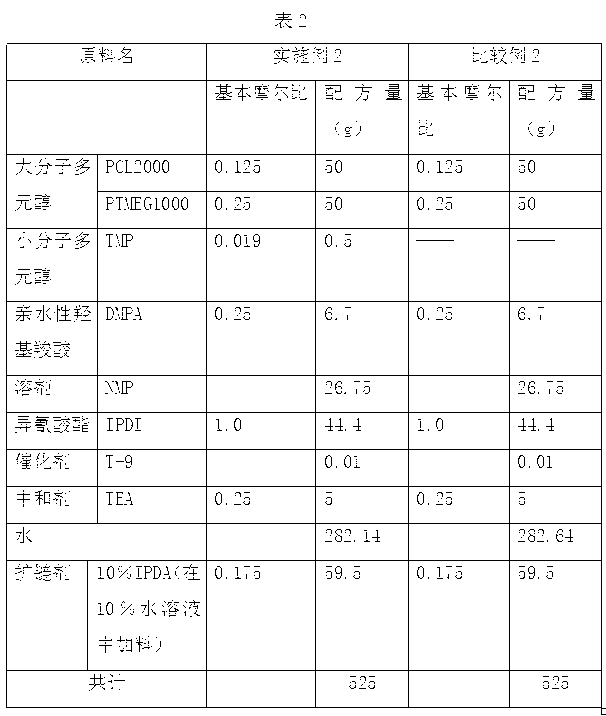

Embodiment 2

[0033] Add 50g PCL2000, 50g PTMEG1000, 0.5g TMP, 6.7g DMPA, 26.75g NMP into the reactor equipped with a stirrer, thermometer, and reflux condenser, heat up to 80°C, add 44.4g IPDI, 0.01g after heating and dissolving for 30 minutes T-9, react at 87°C for 5 hours under stirring to obtain a prepolymer. Then lower the temperature to 60°C, add 5g of triethylamine to neutralize the prepolymer into salt, keep stirring for 20 minutes, then add 282.14g of deionized water under high-speed shearing, add water to emulsify and disperse for 30 minutes, and then add 59.5g of Dilute the amine for chain extension with 10% water, and stir for 30 minutes after the addition to obtain an emulsion.

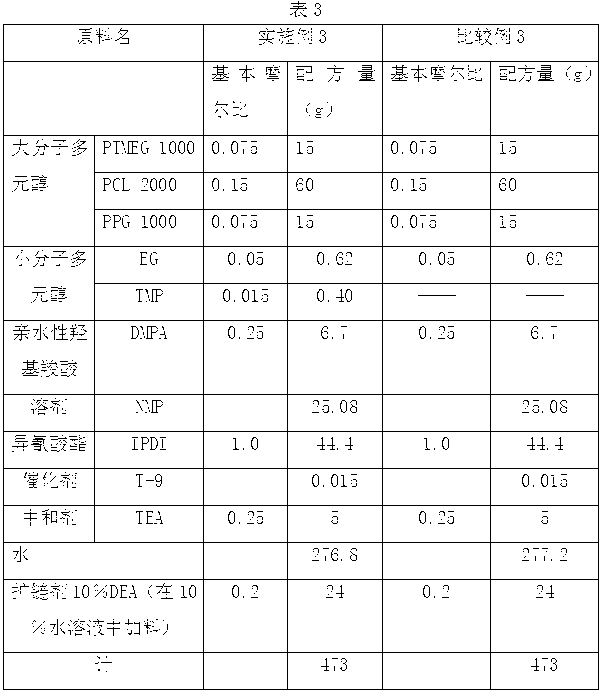

Embodiment 3

[0041]Add 15g PTMEG1000, 60g PCL2000, 15g PPG1000, 0.62g EG, 0.4g TMP, 6.7g DMPA, 25.08g NMP into a reactor equipped with a stirrer, a thermometer, and a reflux condenser, heat up to 80°C, and heat to dissolve for 30 minutes Add 44.4g of IPDI, 0.015g of T-9, and react under stirring at 96°C for 5 hours to obtain a prepolymer. Then cool down to 60°C, add 5g of triethylamine to neutralize the prepolymer into salt, keep stirring for 20 minutes, then add 276.8g of deionized water under high shear and add water to emulsify and disperse for 30 minutes, then add 24g of 10 % water to dilute the amine for chain extension, and stir for 30 minutes after the addition to obtain an emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com