Preparation method of modified aralkyl substituted salicylic acid resin polyvalent metal salt

A multivalent metal salt and multivalent metal technology, which is applied in the direction of copying/marking method, copying with carbon paper, printing, etc., can solve the problems such as the difference in the color development depth of the developer, and achieve the effect of simple process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

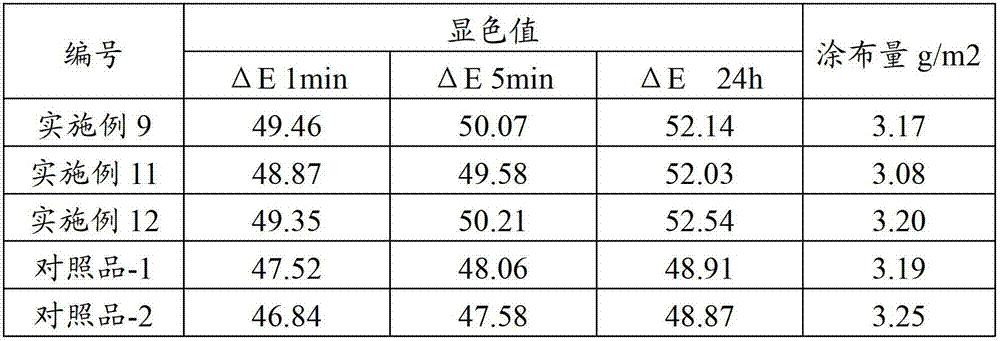

Examples

Embodiment 1

[0033] Add 146 gram salicylic acid, 5.3 gram nickel chloride, 4.23 gram methanesulfonic acid, 106 gram styrene in the there-necked flask equipped with stirrer, reflux condenser, thermometer, be warming up to 125 ℃ while stirring, at 2 220 g of styrene was added dropwise within 1 hour, and the temperature was raised to 180° C. after the addition was completed, and the reaction was carried out for 3 hours. Then the temperature of the reaction system was reduced to 95° C., and 201.5 grams of prepared slurry (45 grams of zinc hydroxide, 5 grams of activated clay, 15 grams of isopropanol, 135 grams of water, 0.3 grams of polyvinyl alcohol, and 1.2 grams of sodium polyacrylate) were added, Reaction was carried out at the reaction temperature for 5 hours, and then rectification under reduced pressure was carried out to distill off unreacted substances. Finally, 525 grams of resinous activated clay modified aralkyl substituted salicylic acid resin zinc salts were obtained.

Embodiment 2

[0035] Carry out according to the method identical with embodiment 1, just replace the methanesulfonic acid in embodiment 1 with active clay. Finally, 523 grams of resinous activated clay modified aralkyl substituted salicylic acid resin zinc salts were obtained.

Embodiment 3

[0037] Carry out according to the method identical with embodiment 1, just replace the nickel chloride in embodiment 1 with lithium chloride. Finally, 526 grams of resinous activated clay modified aralkyl substituted salicylic acid resin zinc salts were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com