Co-production method of high-purity fructose-glucose powder by using fructo-oligosaccharide

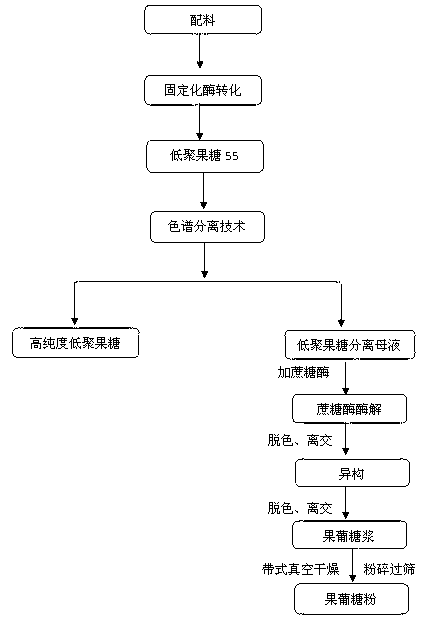

A high-purity fructooligosaccharide technology, applied in fermentation and other directions, can solve the problems of large amount of resin, low recycling rate, low recovery rate of enzyme activity, etc., and achieve the effect of simplifying production process, short production cycle and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for high-purity fructo-oligosaccharide co-production fructose powder, it comprises the steps:

[0038] (1) Immobilized fructosyltransferase: the volume ratio of alumina and enzyme solution is 1:2.5, at pH 6.5, in a 55°C water bath, and oscillating at a speed of 150rpm for 2-4h, add glutaraldehyde solution, cross-linking agent The final concentration of glutaraldehyde is 0.3%. After cross-linking at 4-10°C and 90rpm for 4-6h under slow shaking, filter and wash with pH6.0-7.0 phosphate buffer to wash glutaraldehyde residue and unfixed The free enzyme until the eluate has no enzyme activity, that is, the first immobilized fructosyltransferase is obtained. Add the primary immobilized fructosyltransferase to 20g / L carrageenan solution at a weight percentage of 15%, then embed it with carrageenan, dry it in a 28°C incubator for 5 hours, cut it into small pieces, and place it in 0.2%-0.4% The glutaraldehyde solution was hardened for 6-8 hours, and the glutaraldehyde ...

Embodiment 2

[0050] A method for high-purity fructo-oligosaccharide co-production fructose powder, it comprises the steps:

[0051] (1) Immobilized fructosyltransferase: the volume ratio of alumina and enzyme solution is 1:3, at pH 7.0, in a 55°C water bath, and oscillating at a speed of 200rpm for 2-4h, add glutaraldehyde solution, cross-linking agent The final concentration of glutaraldehyde is 0.4%. After cross-linking at 4-10°C and 100rpm for 4-6h under slow shaking, filter and wash with phosphate buffer solution of pH 6.0-7.0 to wash glutaraldehyde residue and unfixed The free enzyme until the eluate has no enzyme activity, that is, the first immobilized fructosyltransferase is obtained. Add the primary immobilized fructosyltransferase to 20g / L carrageenan solution at a weight percentage of 20%, then embed it with carrageenan, dry it in a 28°C incubator for 5 hours, cut it into small pieces, and place it in 0.2%-0.4% The glutaraldehyde solution was hardened for 6-8 hours, and the glu...

Embodiment 3

[0062] A method for high-purity fructo-oligosaccharide co-production fructose powder, it comprises the steps:

[0063] (1) Immobilized fructosyltransferase: the volume ratio of alumina and enzyme solution is 1:2.5, at pH 6.0, in a 55°C water bath, and oscillating at a speed of 100rpm for 2-4h, add glutaraldehyde solution, cross-linking agent The final concentration of glutaraldehyde is 0.2%. After cross-linking at 4-10°C and 90rpm for 4-6h under slow shaking, filter and wash with pH 7.0 phosphate buffer to wash away glutaraldehyde residue and unfixed free Enzyme, until the eluate has no enzyme activity, the first immobilized fructosyltransferase is obtained.

[0064] (2) The production process parameters of high-purity fructo-oligosaccharide and fructose powder are carried out according to Example 1. The immobilized fructosyltransferase obtained according to the above method is used in the production of high-purity fructo-oligosaccharides and fructoglucose powder with an enzy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com