Superconducting wire component and preparation method thereof

A technology of superconducting wires and components, applied in superconducting devices, superconducting/high-conducting conductors, usage of superconducting elements, etc. Burning and other problems, to achieve the effect of simple structure, smooth surface and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

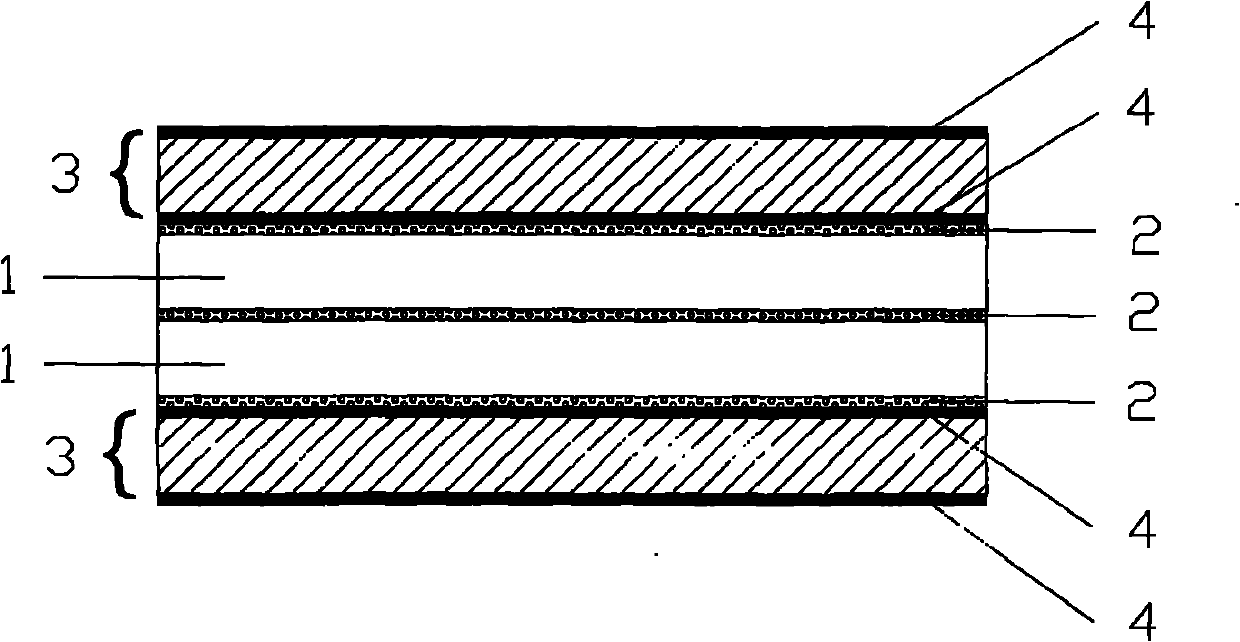

Embodiment 1

[0044] Such as Figure 9 , figure 1 and Figure 10 As shown, two bismuth-based high-temperature superconducting wires 1 are selected, and the two superconducting wires 1 are respectively coiled on the pay-off reel 8, and then two metal reinforcement tapes 3 are selected, and the two metal reinforcement tapes 3 are respectively coiled On the pay-off reel 8. Place the four wire-coiled pay-off reels 8 on the bracket 7 perpendicular to the base 6, and the order of placement is metal reinforcement tape 3 pay-off reel 8, superconducting wire 1 pay-off reel 8, Superconducting wire 1 pay-off reel 8, metal reinforcement tape 3 pay-off reel 8. The width surfaces of the heads of these four wires are brought together from top to bottom in order, and go around the same guide wheel 10, and then pass through the heating tank 12 at a speed of 1.0m / min for heating, and the heating temperature is 200°C , apply 1kg pressing force to the heating plate 14 above the uppermost metal reinforcemen...

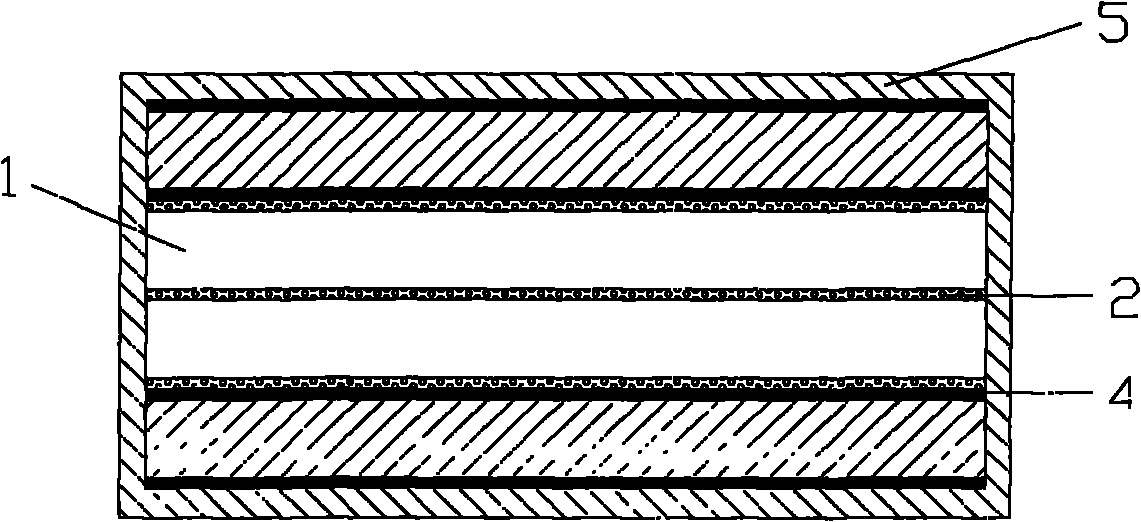

Embodiment 2

[0047] Such as Figure 9 and figure 2 As shown, two bismuth-based high-temperature superconducting wires 1 are selected, and the two superconducting wires 1 are respectively coiled on the pay-off reel 8, and then two metal reinforcement tapes 3 are selected, and the two metal reinforcement tapes 3 are respectively coiled On the pay-off reel 8. Place the four wire-coiled pay-off reels 8 on the bracket 7 perpendicular to the base 6, and the order of placement is metal reinforcement tape 3 pay-off reel 8, superconducting wire 1 pay-off reel 8, Superconducting wire 1 pay-off reel 8, metal reinforcement tape 3 pay-off reel 8. Put the width surfaces of the four wire heads together from top to bottom in order, and bypass the same guide wheel 10, and then pass through the heating tank 12 at a speed of 1.5m / min for heating, and the heating temperature is 250°C , apply 100kg pressing force to the heating plate 14 above the uppermost metal reinforcement strip 3 in the heating tank 12...

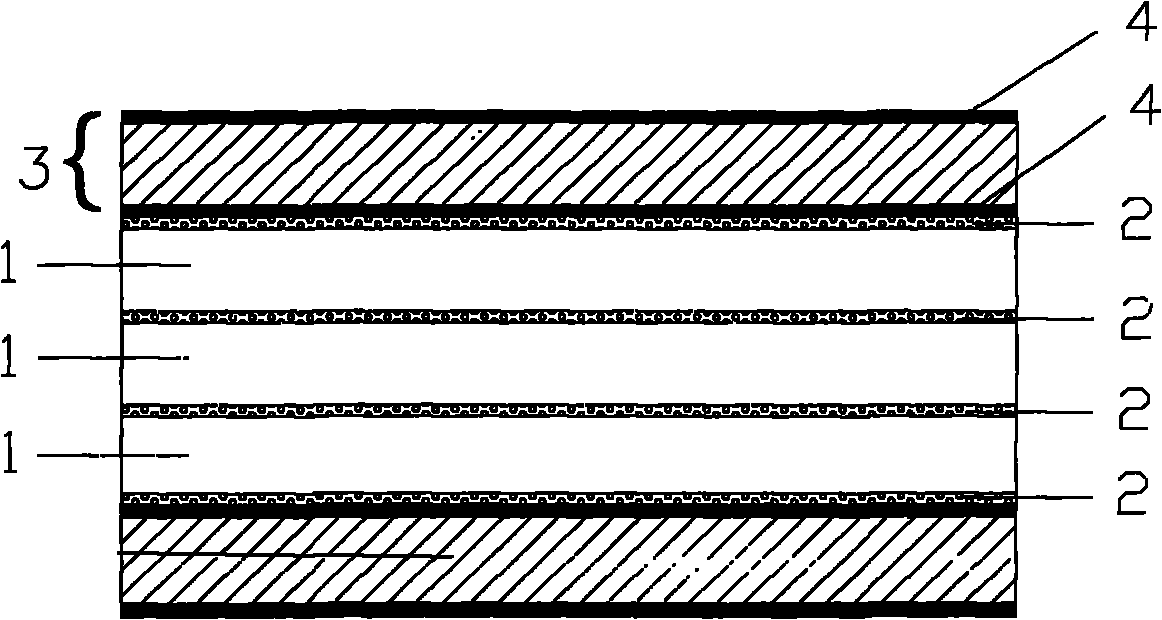

Embodiment 3

[0050] When the superconducting wire assembly 11 is composed of three superconducting wires 1 and two metal reinforcing strips 3, Figure 9 A pay-off reel 8 needs to be added on the bracket 7 on the left side, on which the superconducting wire 1 is coiled.

[0051] Such as Figure 9 and image 3 As shown, three bismuth-based high-temperature superconducting wires 1 are selected, and these three superconducting wires 1 are respectively coiled on the pay-off reel 8, and then two metal reinforcement tapes 3 are selected, and these two metal reinforcement tapes 3 are respectively coiled on the discharge reel 8. 8 on the reel. Place the five pay-off reels 8 that have been coiled on the support 7 perpendicular to the base 6, and the order of placement is metal reinforcement tape 3 pay-off reel 8, superconducting wire 1 pay-off reel 8, Superconducting wire 1 pay-off reel 8, superconducting wire 1 pay-off reel 8, metal reinforcement tape 3 pay-off reel 8. The width surfaces of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com