GaN-based LED with dual reflecting layers

A light-emitting diode, gallium nitride-based technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems that light cannot or is difficult to emit from the side or above, affect the luminous efficiency of the chip, and cannot take out light, etc. The effect of light extraction efficiency, improvement of luminous distribution uniformity, and reduction of current accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

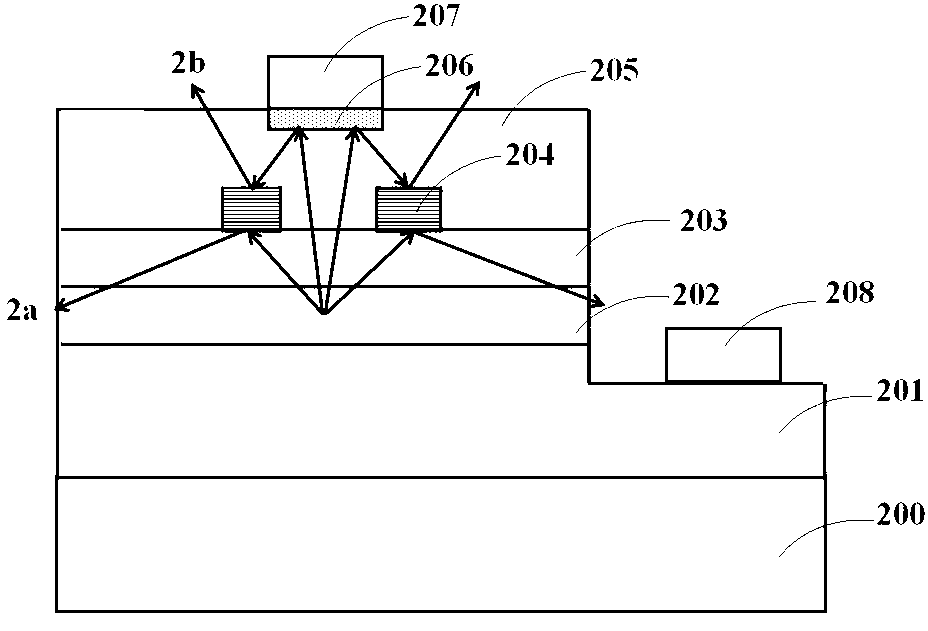

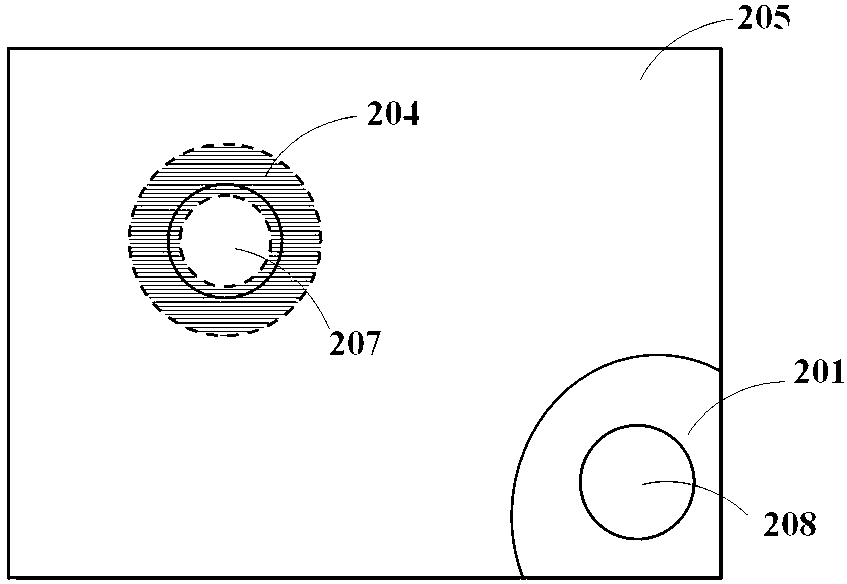

[0061] Such as figure 2 and image 3 A gallium nitride-based high-brightness light-emitting diode with double reflective layers is shown, including: a sapphire substrate 200, an N-type layer 201, a light-emitting region 202, a P-type layer 203, an annular distributed Bragg reflective layer 204, A current spreading layer 205 , a metal reflective layer 206 , a P electrode 207 and an N electrode 208 .

[0062] Specifically, the lowest layer in the above light emitting diode structure is the sapphire substrate 200; the N-type layer 201 is formed on the sapphire substrate 200; the light-emitting region 202 is formed on the N-type layer 201; the P-type layer 203 is formed on the light-emitting On the region 202; the annular distributed Bragg reflection layer 204 is formed on the P-type layer 203; the ITO current spreading layer 205 is formed on the surface of the annular distributed Bragg reflection layer 204 and the P-type layer 203; Al metal reflector Layer 206, formed on the s...

Embodiment 2

[0074] Compared with Embodiment 1, this embodiment discloses a gallium nitride-based high-brightness light-emitting diode with a vertical structure and double reflective layers. In this embodiment, Si is used as the substrate 200, and the N electrode 208 is formed on the back of the substrate, forming a vertical LED device structure.

Embodiment 3

[0076] Compared with Embodiment 1, the electrode structure of the gallium nitride-based LED device disclosed in this embodiment further includes an extended electrode 209 with a width of 10 microns, and a metal reflective layer and a ring-shaped reflective layer can be arranged directly under the extended electrode 209, Further improve the light extraction efficiency. The metal reflective layer can be as large as the extended electrode, and the ring-shaped reflective layer is composed of a ring-shaped structure 204 below the P electrode 207 and a strip-shaped ring structure 210 below the extended electrode 209 . The difference between the annular structure 204 and Embodiment 1 is that the inner diameter of the annular distributed Bragg reflection layer 204 is 80 microns, which is equivalent to the diameter of the P electrode 207, and the inner diameter of the elongated annular structure 210 is 10 microns. , with an outer ring diameter of 20 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com