Low-frequency multidirectional vibration energy recovery device

A vibration energy recovery, multi-directional technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of low energy recovery efficiency, low recovery efficiency, no Problems such as multi-directional recycling function, to achieve the effect of simple design, easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with specific embodiments and drawings, which are explanations of the present invention rather than limitations.

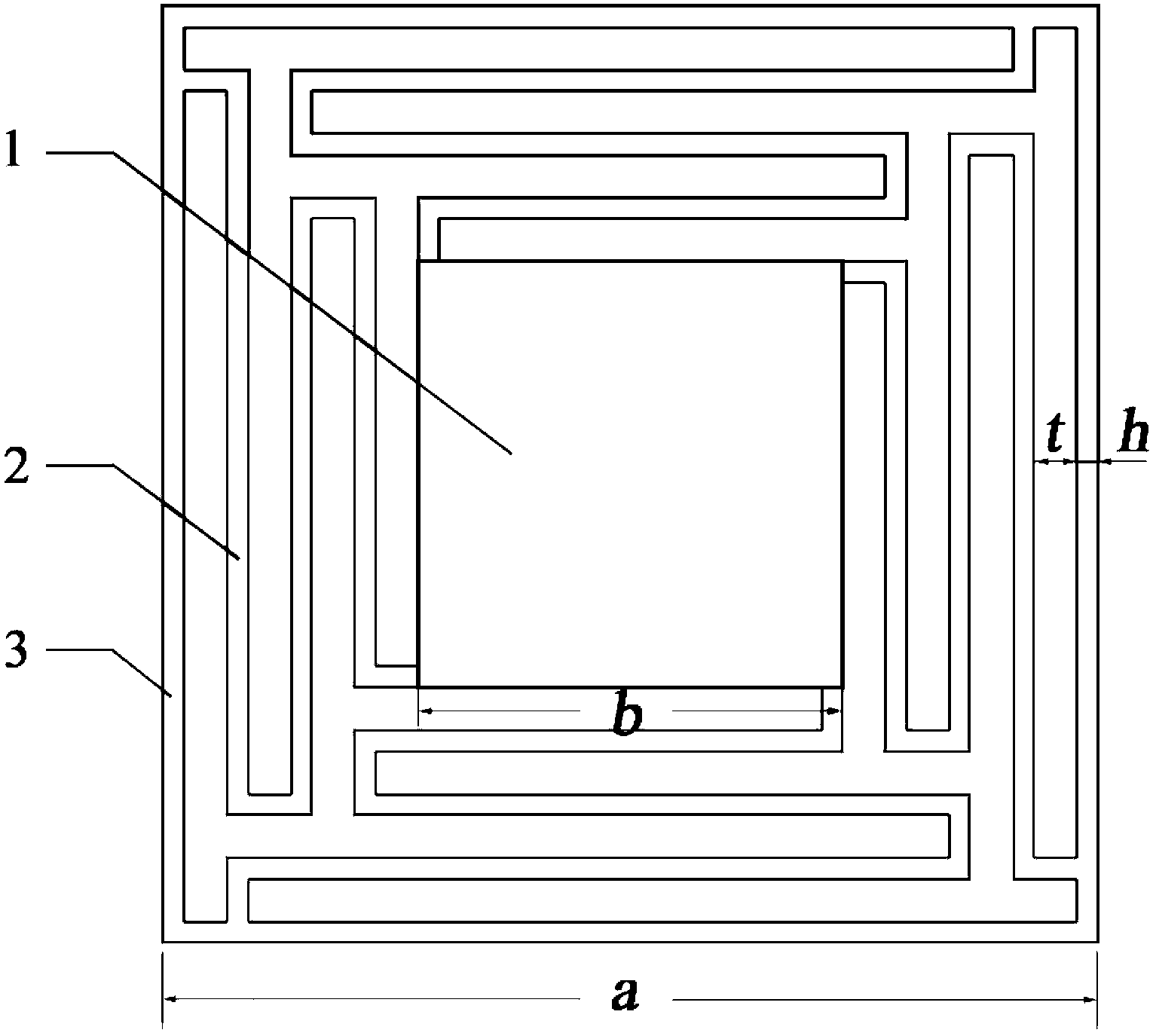

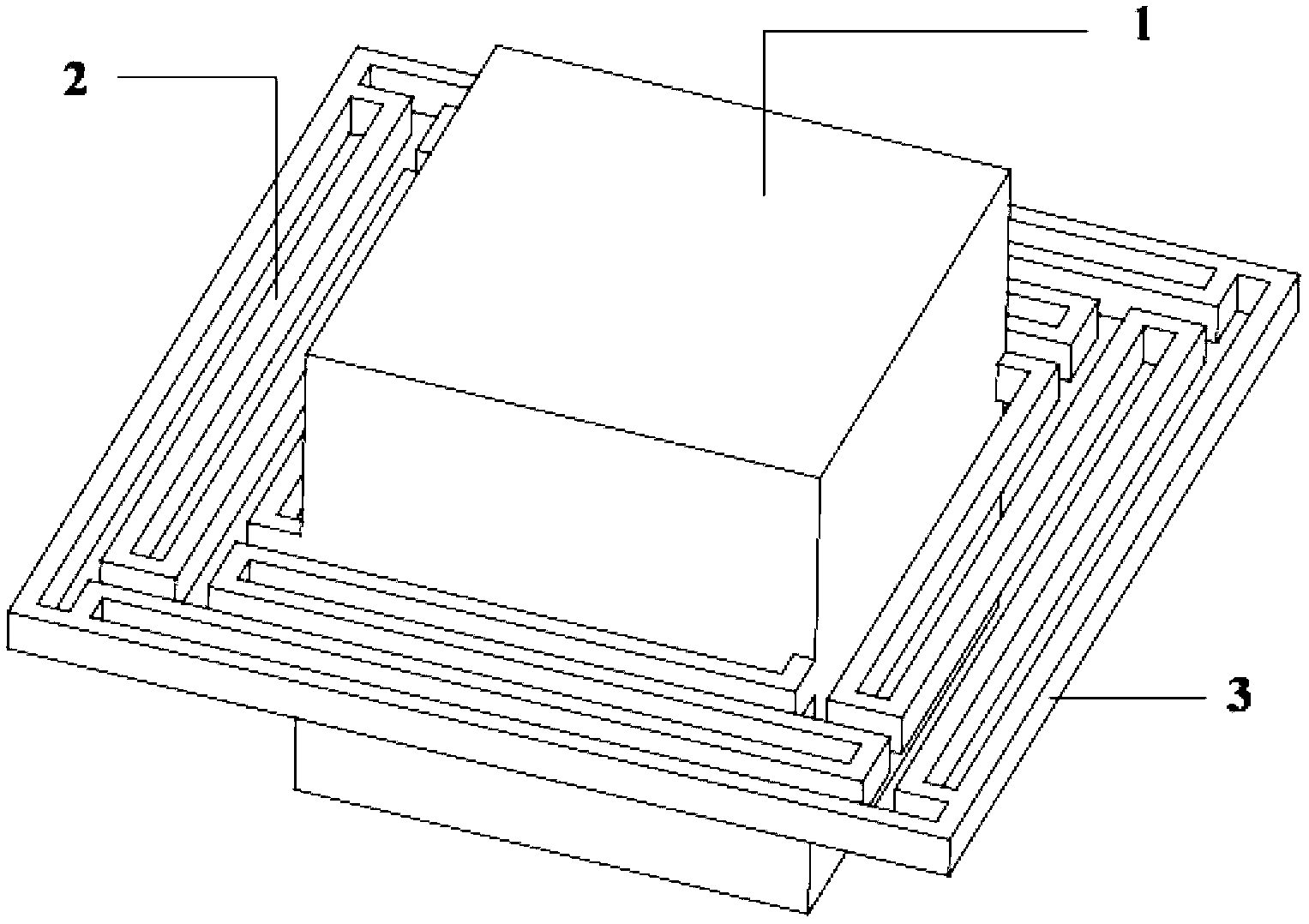

[0041] The low-frequency multi-directional vibration energy recovery device provided is firstly a low-frequency multi-directional multi-resonance solution:

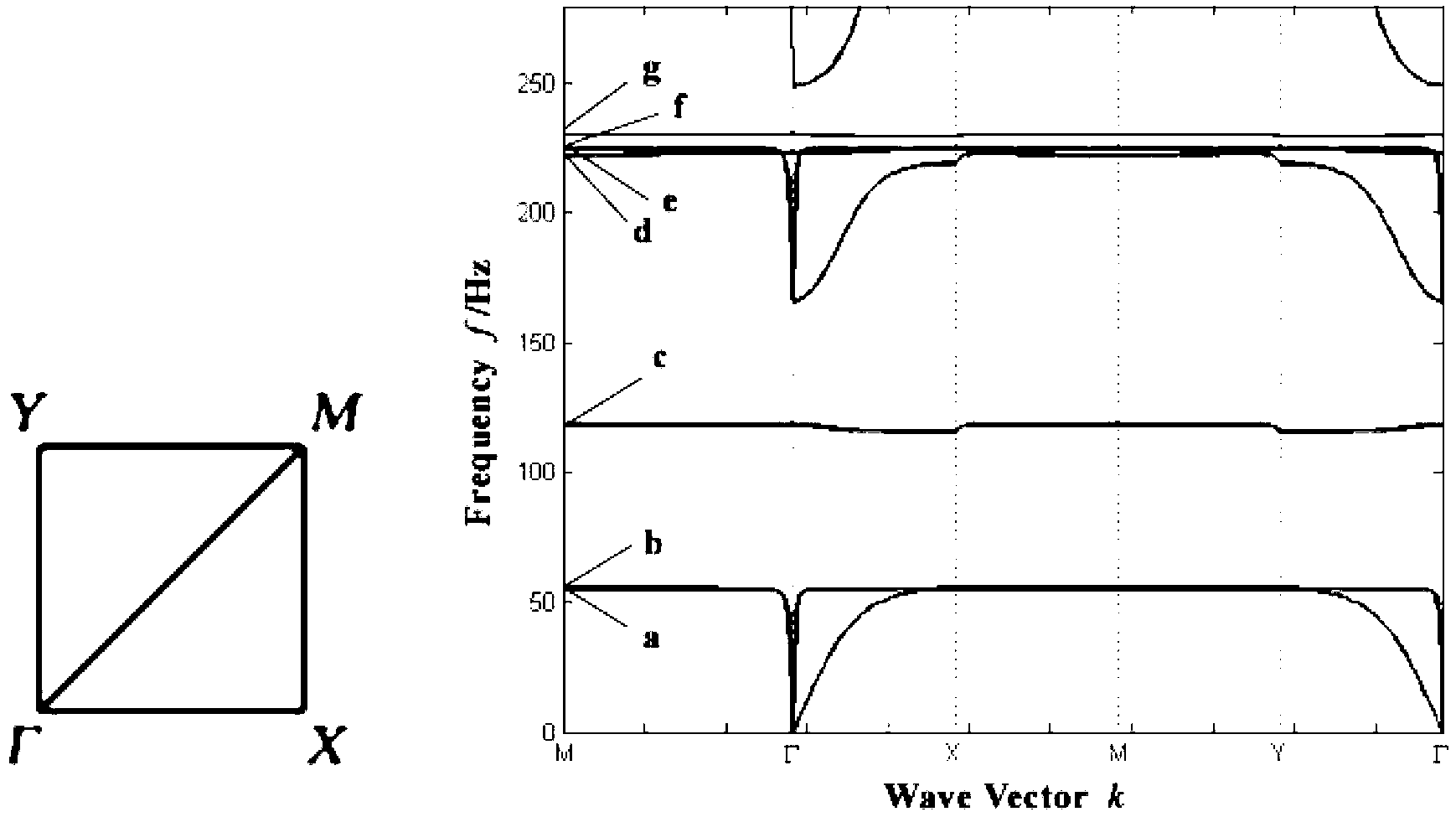

[0042] According to the local resonance mechanism, under the excitation of external elastic waves, the resonant unit resonates and interacts with the low-frequency traveling waves in the matrix, thereby inhibiting its propagation and resulting in the generation of a band gap. The position and width of the bandgap can be adjusted by the structure of the phononic crystal (such as triangular, tetragonal, etc.), size (such as lattice constant), composition (such as two-component, three-component), material and filling rate, and It has nothing to do with the arrangement of the resonant units. Liu Zhengyou and others analyzed the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com