Method and device for continuous laminating of flexible thin film with multilayer structure

A technology of flexible film and multi-layer structure, applied in the direction of chemical instruments and methods, lamination, lamination device, etc., can solve the problem that the flexible film cannot be laminated multiple times, and achieve simplified production process and equipment complexity, mold Accurate incision alignment and stable roll-to-roll delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

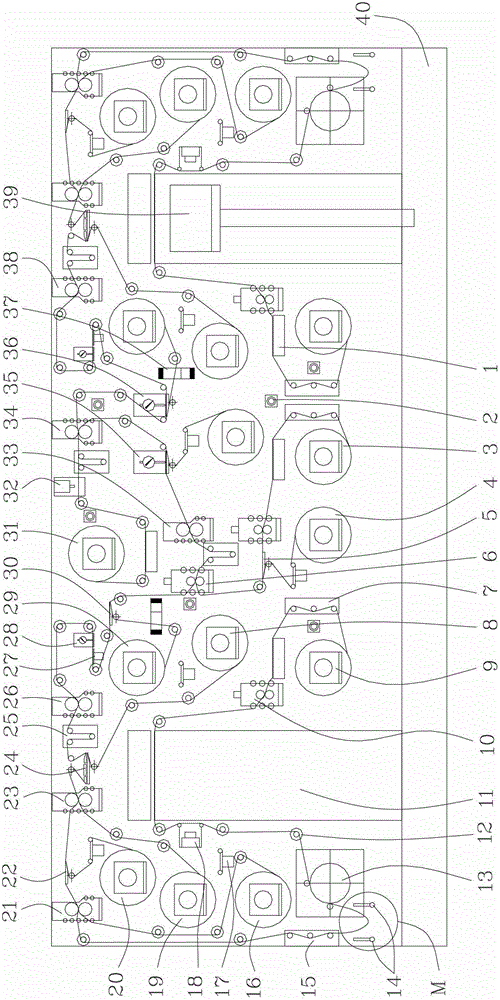

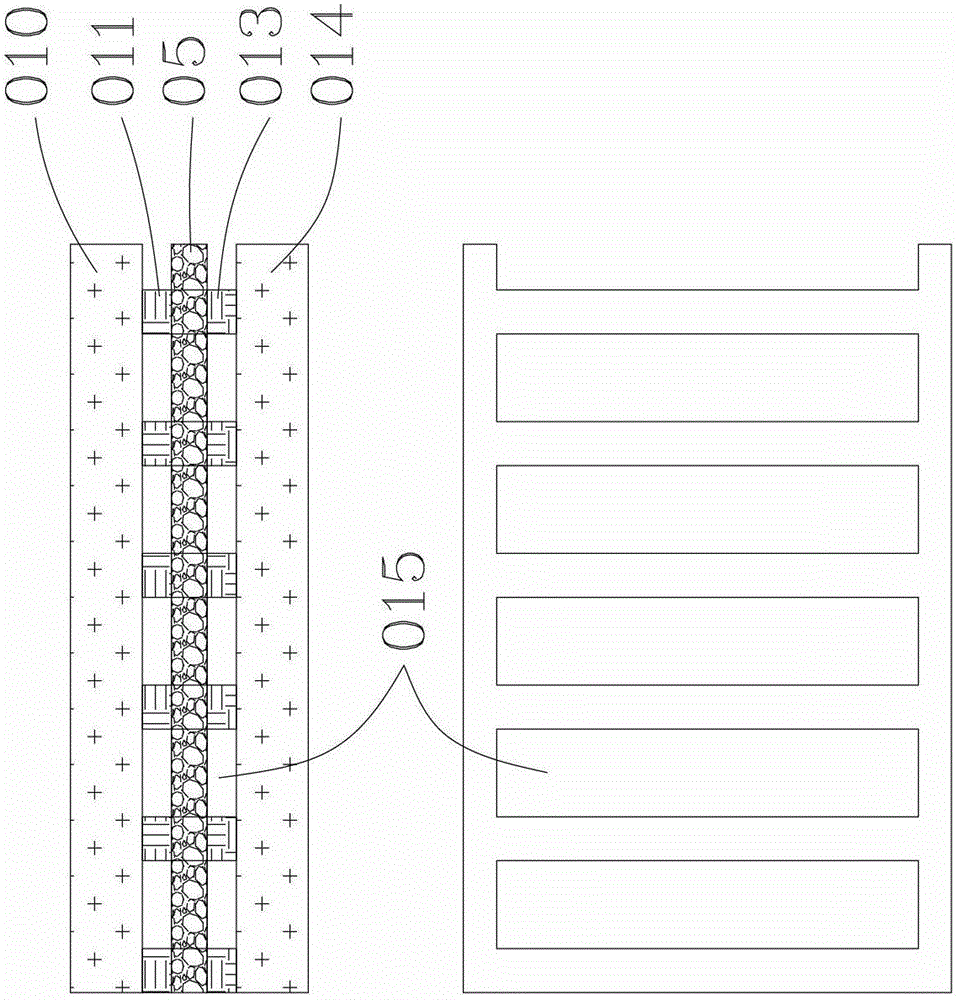

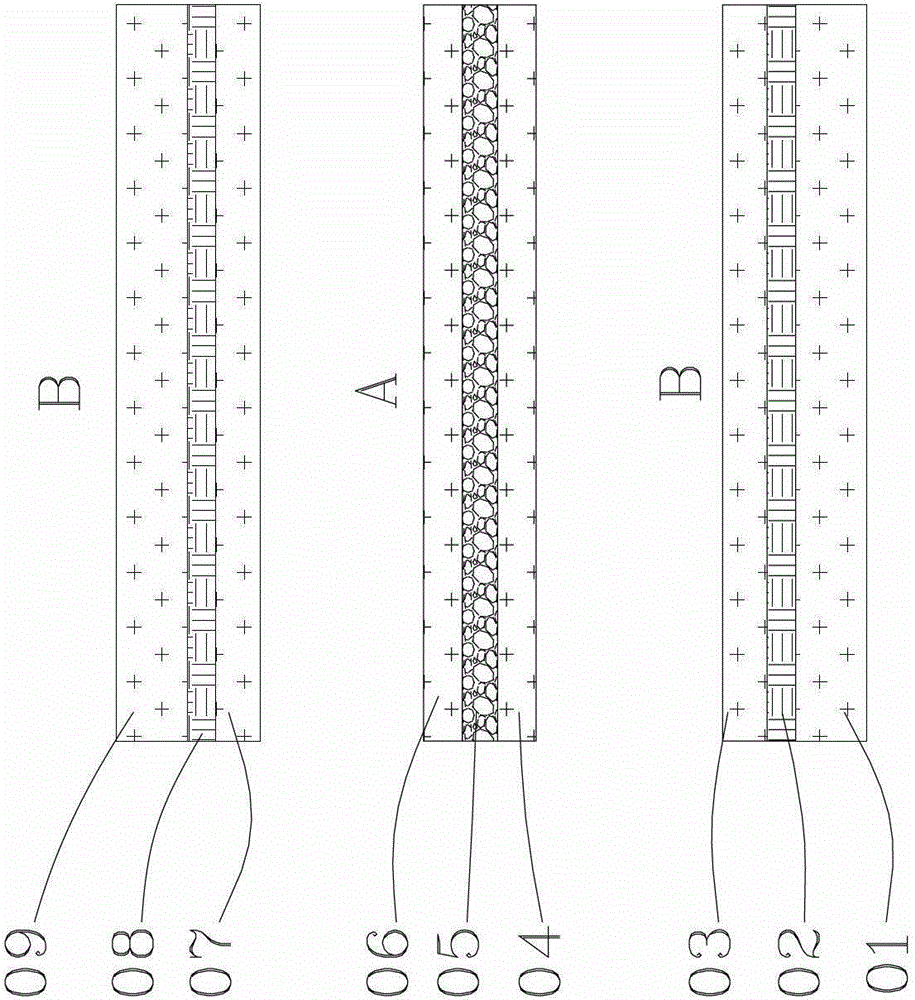

[0038] refer to figure 1 , the technical process of the present embodiment is specifically introduced as follows:

[0039] Wherein, for implementing the overall structure of the equipment adopted in the technique of the present embodiment comprising frame 40, discharge roller 3,9,16,19, conveying pair of rollers 6,10,21,23,26,33,34,38 , idler roller 12, die-cutting device 11, vision system 18, friction roller 13, floating material detection module 14, deviation correction roller 7, 15, small receiving table 17, small peeling module 5, 22, 30, large peeling module 24, floating roller 25, peeling detection module 28, knife repairing table 27, material breaking detection module 37, large material receiving table 1, ion air bar 2, lamination alignment detection modules 35, 36, finished product detection module 32, receiving Rollers 4, 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com