Magnesium alloy structural part and magnesium alloy structural assembly

A technology for structural components and structural components, which is applied in the field of magnesium alloy structural components and magnesium alloy structural components, can solve the problems of low melting point, poor welding ability, and strong affinity of magnesium alloys, and achieve simple structure, flexible and convenient assembly, and convenient processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

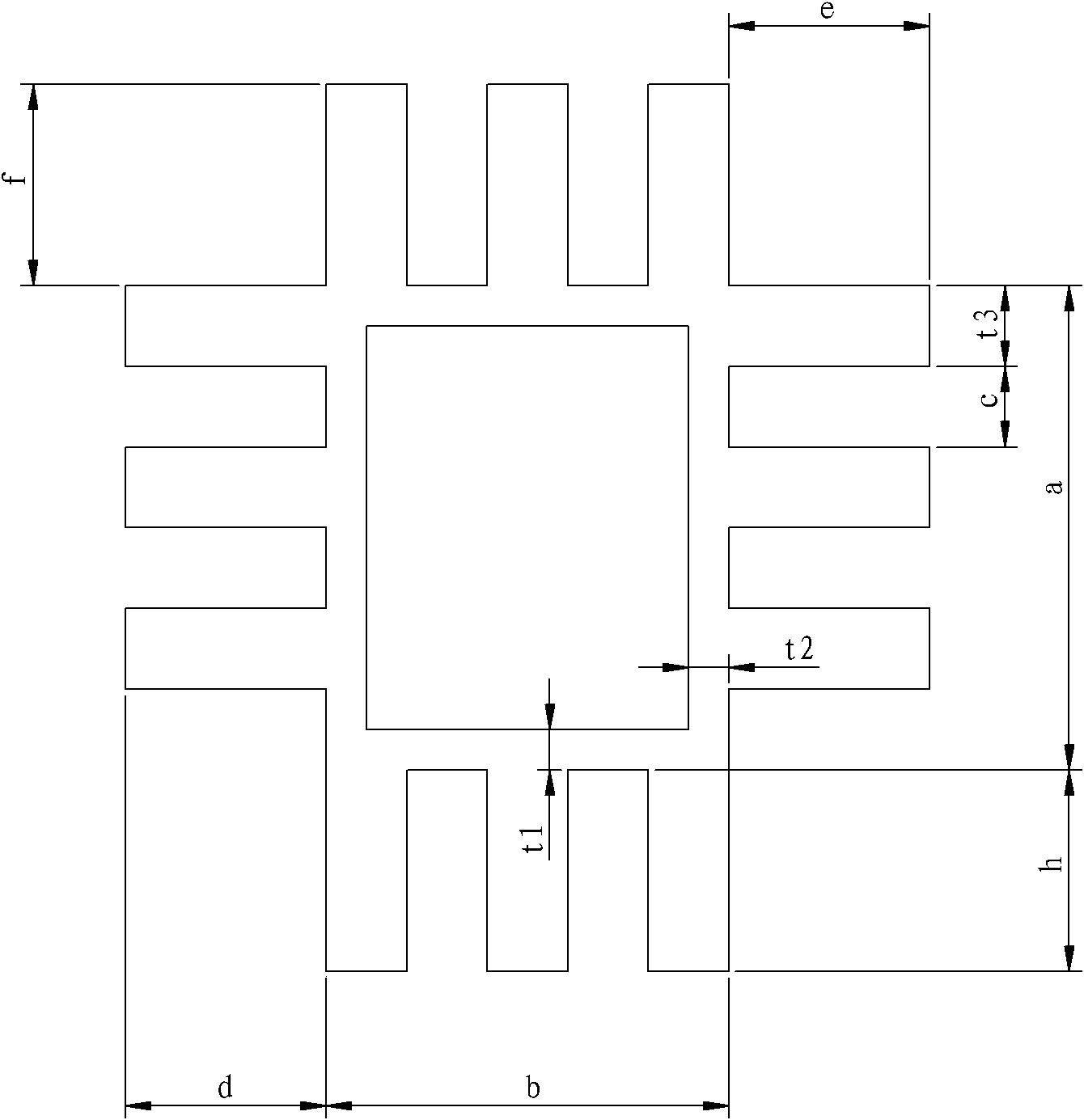

[0058] In this embodiment, the cross section of the body 1a of the first structure 100a and the body 1b of the second structure 100b are the same, and the axes of the first structure 100a and the second structure 100b are assembled perpendicular to each other, wherein the first structure The thickness of the gap between two adjacent connecting flaps 2a of the member 100a is equal to the thickness of the gap between the adjacent two connecting flaps 2b of the second structural member 100b, while the connecting flaps of the first structural member 100a 2a and the connecting flaps 2b of the second structural member 100b are respectively equal in thickness and number.

[0059] like figure 2 As shown, one end of the coupling 200 is connected to the first structural member 100a through the first bolt 300a, and the other end of the coupling 200 is connected to the second structural member 100b through the second bolt 300b, for example, the first bolt 300a and the second bolt 300a 3...

Embodiment 2

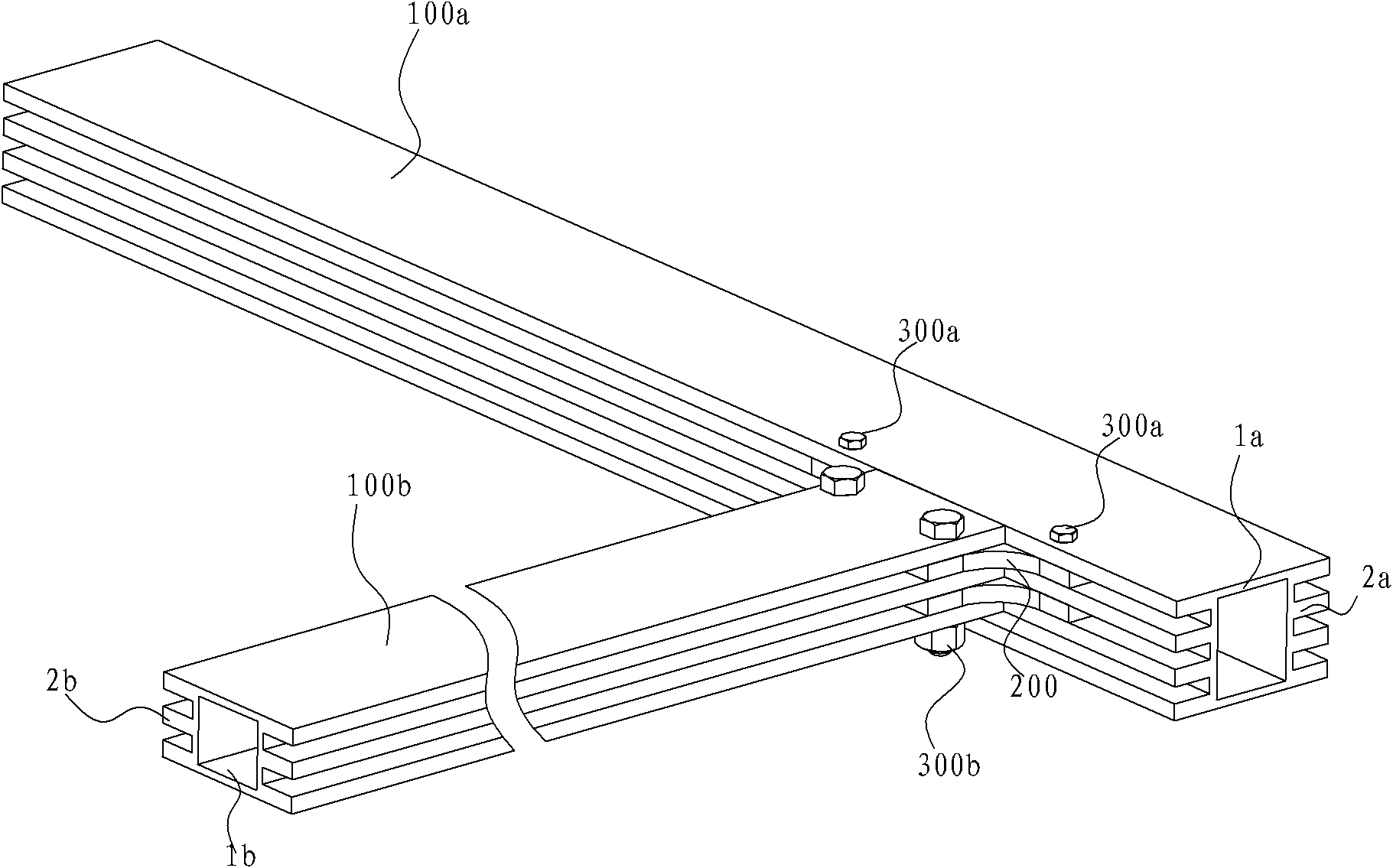

[0062] In this embodiment, the body 1a of the first structure 100a and the body 1b of the second structure 100b have different cross-sections, and the axes of the first structure 100a and the second structure 100b are assembled perpendicular to each other. like image 3 As shown in , the thickness of the gap between two adjacent connecting flaps 2a of the first structural member 100a is equal to the thickness of the gap between two adjacent connecting flaps 2b of the second structural member 100b, while the first The connecting flaps 2a of the structural member 100a and the connecting flaps 2b of the second structural member 100b have the same thickness but different numbers.

[0063] like image 3 As shown, one end of the coupling 200 is connected to the first structural member 100a through the first bolt 300a, and the other end of the coupling 200 is connected to the second structural member 100b through the second bolt 300b, for example, the first bolt 300a and the second ...

Embodiment 3

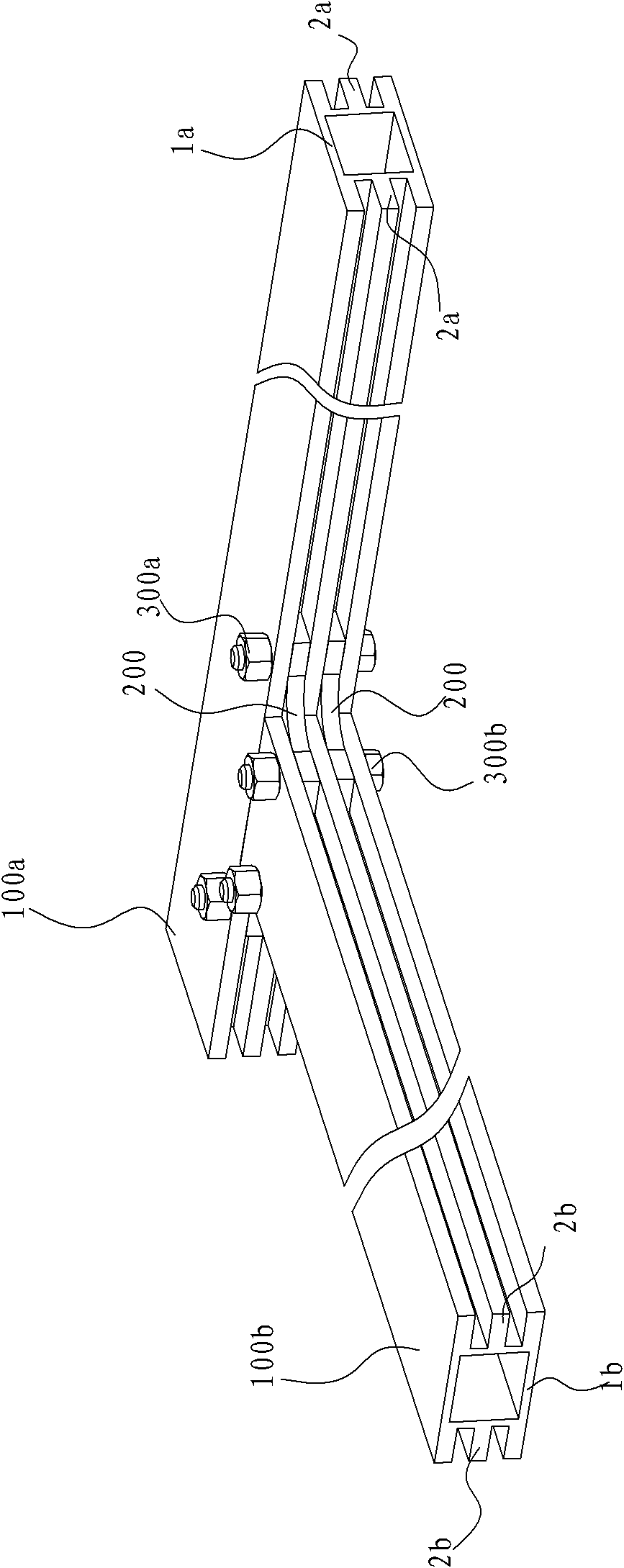

[0066] In this embodiment, the body 1a of the first structure 100a and the body 1b of the second structure 100b have different cross-sections, and the axes of the first structure 100a and the second structure 100b are assembled obliquely to each other. like Figure 4 As shown in , the thickness of the gap between two adjacent connecting flaps 2a of the first structural member 100a is equal to the thickness of the gap between two adjacent connecting flaps 2b of the second structural member 100b, while the first The connecting flaps 2a of the structural member 100a and the connecting flaps 2b of the second structural member 100b have the same thickness but different numbers.

[0067] In this embodiment, one of the first structural member 100a and the second structural member 100b can be pre-cut beveled, for example, as Figure 4 As shown, the end of the second structural member 100b mated with the first structural member 100a is cut with a proper bevel. Then, one end of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com