Carbon/carbon/silicon carbide composite material and preparation method

A composite material and silicon carbide technology, which is applied in the fields of carbon/carbon/silicon carbide composite materials and their preparation, and carbon/carbon/silicon carbide composite materials and their preparation for high-temperature furnaces. Strength reduction and other problems, to achieve the effect of improving service life, simple process and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

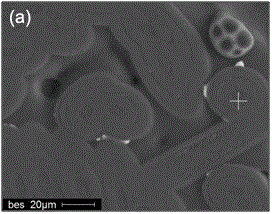

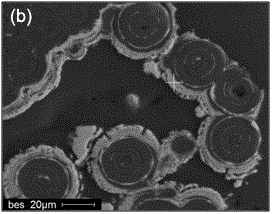

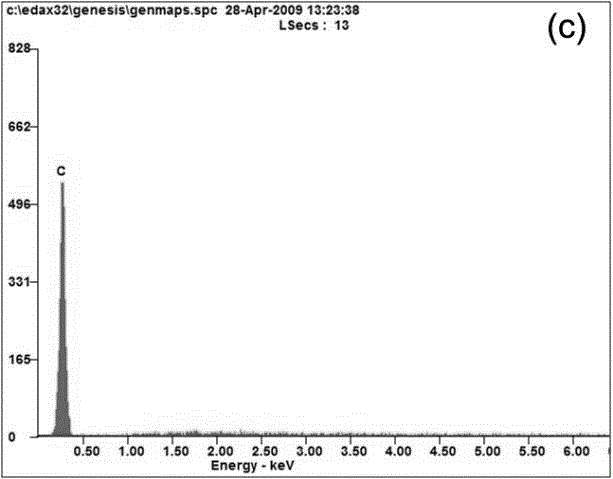

[0033] A carbon / carbon / silicon carbide composite material, which alternately densifies pyrolytic carbon and silicon carbide or mixes densification of pyrolytic carbon and silicon carbide by using chemical vapor infiltration on a carbon fiber preform (in this embodiment, alternate Densification), and then prepared by machining and purification, its density is 1.3g / ㎝ 3 ~2.5g / ㎝ 3 (This embodiment is 1.65g / ㎝ 3 ), bending strength ≥ 300MPa, fracture toughness ≥ 15MPa m 1 / 2 .

[0034] A kind of preparation method of carbon / carbon / silicon carbide composite material, it comprises the following steps:

[0035] (1) Preparation of carbon fiber prefabricated body: carbon fiber is made into a carbon fiber prefabricated body with the required structure and shape according to the shape and performance requirements of the product, and its density is 0.2g / ㎝ 3 ~1.0g / ㎝ 3 (This embodiment is 0.50g / ㎝ 3 );

[0036] When preparing carbon fiber prefabricated body, carbon fiber mesh tire and me...

Embodiment 2

[0046] In step (2) of the present invention, first chemical vapor infiltration pyrolytic carbon, infiltration time 20 hours, then chemical vapor infiltration silicon carbide, infiltration time 20 hours, alternate 5 times, finally chemical vapor infiltration silicon carbide, the total time of chemical vapor infiltration is 200 hours, the resulting density is 1.92g / ㎝ 3 carbon / carbon / silicon carbide composite body.

[0047] The rest are the same as embodiment 1.

[0048] The invention adopts the alternate densification method of pyrolytic carbon and silicon carbide, and can prepare carbon / carbon / silicon carbide composite material with higher density in a shorter time. At the same time, due to the chemical vapor infiltration of silicon carbide when the material density is low, the silicon carbide can fully penetrate into the carbon fiber matrix, ensuring the high bonding strength of silicon carbide and carbon fiber matrix, which can effectively inhibit the silicon vapor on the co...

Embodiment 3

[0050] In order to further improve the corrosion resistance of the carbon / carbon / silicon carbide composite material in the present invention, in step (2), the pyrolytic carbon and silicon carbide are alternately densified as firstly chemical vapor infiltrating silicon carbide, and first wrapping a layer on the surface of the carbon fiber Silicon carbide, followed by alternating chemical vapor infiltration of pyrolytic carbon and silicon carbide, and finally chemical vapor infiltration of silicon carbide, the carbon / carbon / silicon carbide composite material prepared in this way has the best corrosion resistance.

[0051] Remaining with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com