Decolorizing and deodorizing method of collagen peptide of abyssal fishes

A collagen peptide and deodorization technology, applied in the direction of specific peptides, connective tissue peptides, animal/human proteins, etc., can solve the problem of decolorization and deodorization of deep-sea fish collagenase hydrolyzate, so as to improve product quality and expand application. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 8g of urease to 8L cod skin collagen peptide solution with 32% Brix, and adjust the pH of the solution to 4.5. After incubating at 40°C for 15min, add 40g of activated carbon, and decolorize and deodorize at 40°C for 15min. Utilize dish centrifuge at 5000rpm under centrifugal 20min to remove gac, then utilize anion exchange resin to its decolorization deodorization 15min at 20 DEG C, the solution that obtains is slowly added 0.4L dehydrated alcohol under stirring, static at 20 DEG C Place it for 60 minutes; finally, the decolorized and deodorized collagen peptide solution is spray-dried at 150° C. at the air inlet temperature and 70° C. at the air outlet temperature by using a spray dryer to obtain 1.8 kg with a moisture content of 6% (w / w ) about collagen peptide powder.

Embodiment 2

[0027] Add 30g urease to the 6L shark bone collagen peptide solution that is 38% in Brix, and adjust the pH of the solution to 6.0. After incubating at 30°C for 60min, add 90g of activated carbon, and decolorize and deodorize after 60min at 30°C. Utilize disc centrifuge at 6000rpm under centrifugal 40min to remove activated carbon, utilize macroporous adsorption resin to decolorize and deodorize 30min to it at 40 DEG C then, the solution obtained slowly adds 0.9L dehydrated alcohol under stirring, at 40 DEG C Leave standstill 15min; The collagen peptide solution of the depigmentation decolouring that obtains at last utilizes spray drier, is 190 DEG C at air inlet temperature, carries out spray drying under 100 DEG C of air outlet temperature, can obtain 1.7kg moisture content and be 6.5% ( w / w) about collagen peptide powder.

Embodiment 3

[0029] Add 25g urease to 10L shark bone collagen peptide solution with 40% Brix, and adjust the pH of the solution to 5.0, after incubating at 35°C for 30min, add 100g of activated carbon, and decolorize and deodorize after 30min at 35°C. Utilize disc centrifuge to remove gac at 5500rpm by centrifugation for 30min, then utilize chelating resin to decolorize and deodorize it for 60min at 35°C, and slowly add 1.0L absolute ethanol to the solution obtained under stirring, statically at 30°C Put 30min; Finally, the collagen peptide solution of depigmentation decolorization that will obtain utilizes spray drier, is 170 DEG C at air inlet temperature, carries out spray drying under 80 DEG C of air outlet temperature, can obtain 3.0kg moisture content and be 6.0% (w / w) about collagen peptide powder.

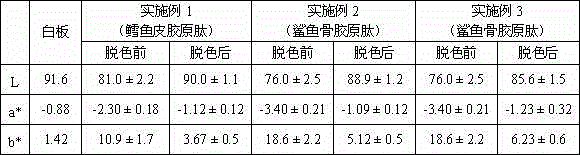

[0030] The color of the collagen peptide samples before and after decolorization and deodorization was measured by a colorimeter, and the results are shown in Table 1. It can be s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com