Resin composition capable of direct evaporation molding and preparation method thereof

A resin composition and a direct technology, applied in the field of resin compositions, can solve the problems of heavy investment, high process precision requirements, low evaporation yield, etc., and achieve VOC content reduction, simple operation, and high evaporation yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a resin composition and a preparation method that can be directly formed by vapor deposition, and the preparation method includes the following steps:

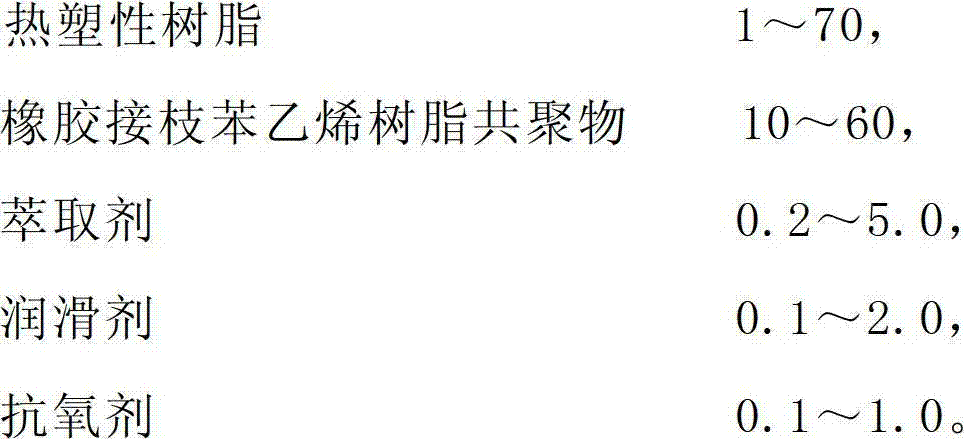

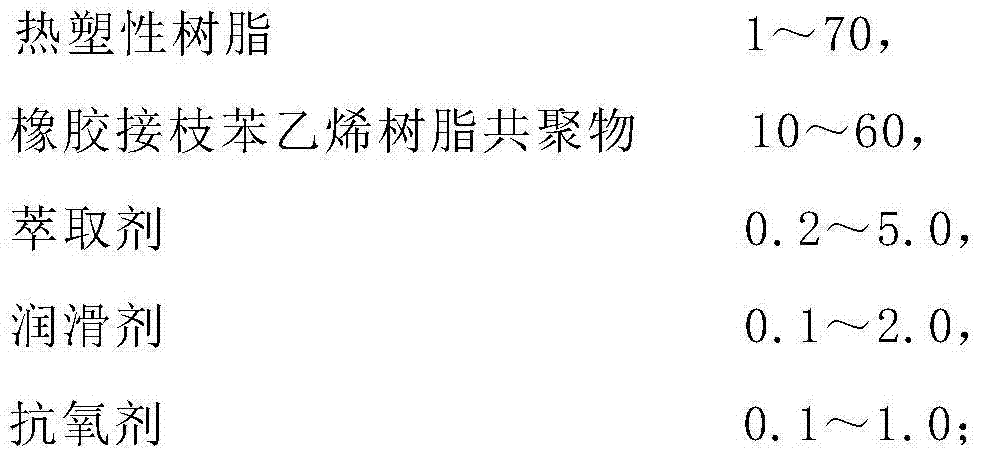

[0034] Prepare materials according to the following components and contents:

[0035] thermoplastic resin

PC

70

Rubber grafted styrene resin copolymer

ABS

10

Extracting agent

0.2

silicone oil

0.1

1076

0.1

[0036] The mass percent content of rubber in the above-mentioned ABS is 60%;

[0037] (2) Mix ethanol and ABS evenly by spraying in a low-speed mixer (mixing time is 2 minutes) to prepare a premix, and then add the premix, PC and other components to the extrusion line with L / D=30 In the machine, the temperature is set at 200°C, the absolute pressure in the degassing zone is 300mbar, and the degassing zone is composed of toothed conveying elements with a l...

Embodiment 2

[0039] This embodiment provides a resin composition and a preparation method that can be directly formed by vapor deposition, and the method includes the following steps:

[0040] (1) Prepare materials according to the following components and contents:

[0041] thermoplastic resin

PC

55

Rubber grafted styrene resin copolymer

ABS

45

Extracting agent

1.0

lubricant

PETS

0.2

antioxidant

B900

0.2

[0042] The mass percent content of rubber in the above-mentioned ABS is 40%;

[0043](2) Mix ethanol and ABS evenly by spraying in a low-speed mixer (mixing time is 3 minutes) to prepare a premix, and then add the premix, PC and other components to the extrusion line with L / D=40 In the machine, the temperature is set at 240°C, the absolute pressure in the degassing zone is 300mbar, and the degassing zone is composed of toothed conveying elements with a length of 56mm. The residence time of the ...

Embodiment 3

[0045] This embodiment provides a resin composition and a preparation method that can be directly formed by vapor deposition, and the method includes the following steps:

[0046] (1) Prepare materials according to the following components and contents:

[0047] thermoplastic resin

Blend of polyamide and polymethyl methacrylate

35

Rubber grafted styrene resin copolymer

ASA

25

Extracting agent

ethanol

2.0

lubricant

2.0

antioxidant

B900

0.5

[0048] The mass percent content of rubber in the above-mentioned ASA resin is 80%;

[0049] (2) In a low-speed mixer, mix ethanol and ABS evenly by spraying (mixing time is 5 minutes) to prepare a premix, and then add the premix, PC and other components to the extruder with L / D==48 During the discharge, the temperature is set at 280°C, the absolute pressure in the degassing zone is 50mbar, and the degassing zone is composed of toothed con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com