Waterborne ultraviolet-heat double-curing polyaniline anticorrosive paint and preparation method thereof

A technology of anti-corrosion coatings and water-based curing agents, applied in anti-corrosion coatings, coatings, etc., can solve problems such as polluting the environment and diluents irritating the skin, and achieve the effect of increasing anti-corrosion performance and improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

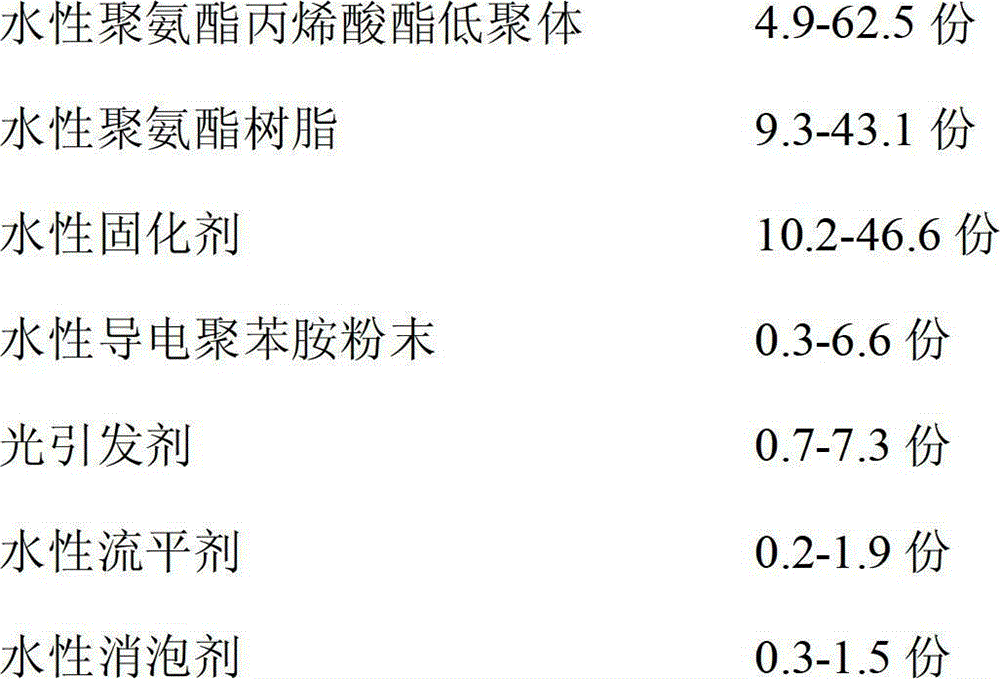

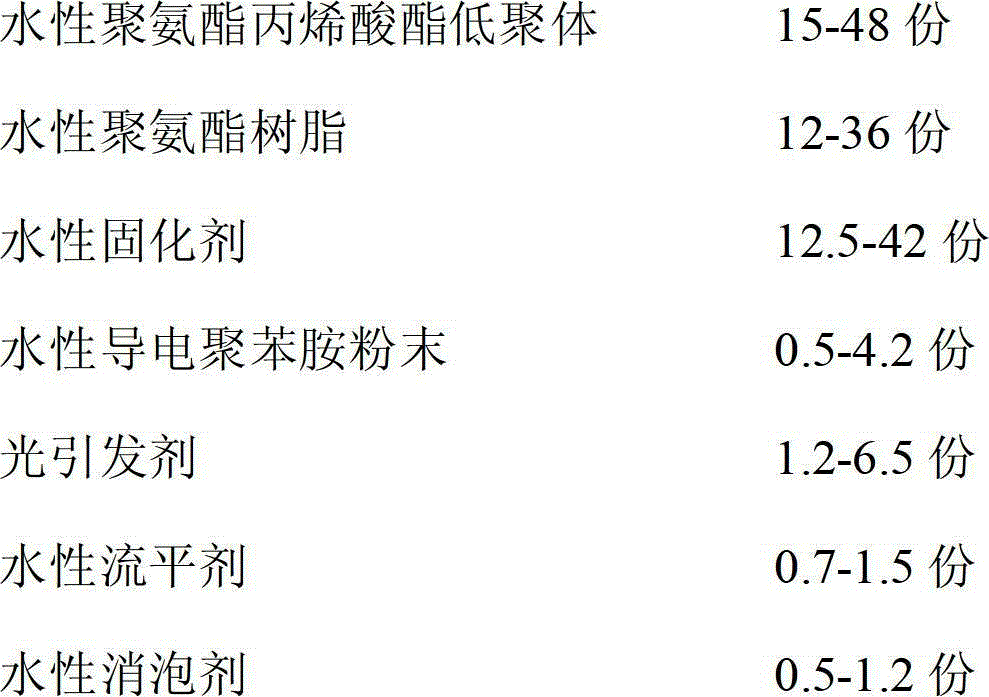

[0066] The preparation method of water-based ultraviolet light-heat dual curing polyaniline anticorrosion coating of the present invention, comprises the following steps: by the weight part of the component of waterborne ultraviolet light-thermal double curing polyaniline anticorrosion coating,

[0067] (1) Put the water-based polyurethane acrylate oligomer, water-based polyurethane resin and water-based polyaniline powder into a sand mill tank, and stir at a speed of 600-1200 rpm for 0.5-3 hours to obtain a mixture;

[0068] (2) Add a photoinitiator, a leveling agent and a defoamer to the mixture obtained in step (1), and stir at a speed of 900-1500 rpm for 0.5-3 hours;

[0069] (3) Add a water-based curing agent, and stir at a speed of 800-1100 rpm for 0.5-3 minutes to obtain a dark green water-based UV-heat dual-curing polyaniline anti-corrosion coating;

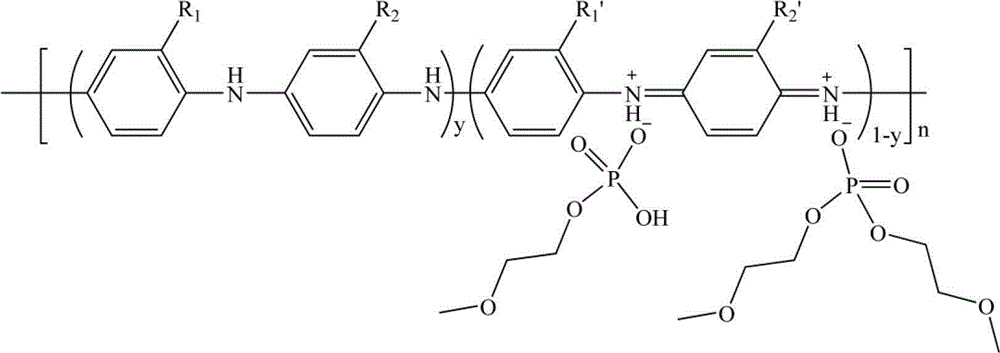

[0070] Described waterborne polyurethane acrylate oligomer is cationic waterborne polyurethane acrylate oligomer or non...

Embodiment 1

[0092] Waterborne UV-heat dual curing polyaniline anti-corrosion coating WP 1 Preparation of:

[0093] By WP in Table 2 1 parts by weight,

[0094] (1) Put the water-based polyurethane acrylate oligomer, water-based polyurethane resin and water-based polyaniline powder in the sand mill tank, and stir for 3 hours at a speed of 600 rpm;

[0095] (2) Add the photoinitiator, leveling agent and defoamer to the mixture obtained in step (1), and stir at a speed of 1500 rpm for 0.5 hours;

[0096] (3) Add a water-based curing agent to the mixture obtained in step (2), and stir at a speed of 800 rpm for 3 minutes to obtain a water-based UV-thermal dual-curing polyaniline anticorrosive coating WP 1 .

[0097] The obtained water-based UV-heat dual curing polyaniline anticorrosion coating WP 1 Spray on pre-polished, degreased and derusted metal steel plates, leveling at 50°C for 3 minutes, irradiating with a 3kw UV lamp, curing time 15s, and then baking at 60°C for 2 minutes to get WP ...

Embodiment 2

[0099] Waterborne UV-heat dual curing polyaniline anti-corrosion coating WP 2 Preparation of:

[0100] By WP in Table 2 2 parts by weight,

[0101] (1) Put the water-based polyurethane acrylate oligomer, water-based polyurethane resin and water-based polyaniline powder in the sand mill tank, and stir at a speed of 1200 rpm for 0.5 hours;

[0102] (2) Add photoinitiator, leveling agent and defoamer to the mixture obtained in step (1), and stir at a speed of 900 rpm for 3 hours;

[0103] (3) Add a water-based curing agent to the mixture obtained in step (2), and stir at a speed of 1100 rpm for 0.5 minutes to obtain a water-based UV-thermal dual-curing polyaniline anticorrosive coating WP 2 .

[0104] The obtained water-based UV-heat dual curing polyaniline anticorrosion coating WP 2 Spray on pre-polished, degreased, and derusted metal steel plates, leveling at 50°C for 3 minutes, irradiating with a 3kw UV lamp, curing time 30s, and then baking at 45°C for 5 minutes to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com