Water-based coating for interior and exterior walls of buildings and preparation method of water-based coating

A water-based technology in buildings, applied in coatings and other directions, can solve problems such as poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

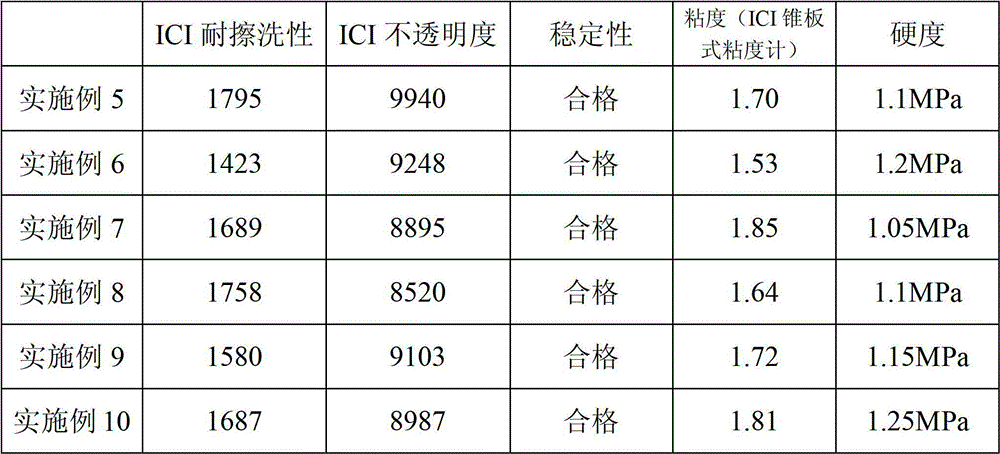

Examples

Embodiment 1

[0043] Preparation of emulsion polymer A of methacrylic acid, 2-hydroxyethyl acrylate, methyl methacrylate and 2-ethylhexyl acrylate by using phosphate ester surfactants:

[0044] By mixing 224g of water, 0.8g of ammonium carbonate, 1.07g of ammonium lauryl sulfate (Sipon TM L-22), 6.4g nonylphenol ethoxylate phosphate (Dextrol TM OC-110), 24 g methacrylic acid, 15.2 g 2-hydroxyethyl acrylate, 488 g methyl methacrylate, and 272.8 g 2-ethylhexyl acrylate to prepare a monomer premix. Initiator A was prepared by dissolving 0.8 g of ammonium persulfate in 8 g of water. Initiator B was prepared by dissolving 1.2 g of ammonium persulfate in 80 g of water. 760g of water, 8g of nonylphenol ethoxylated phosphate (Dextrol TM OC-110), 0.72 g of ammonium carbonate and 1.29 g of 28 wt% ammonium hydroxide were charged into a 3 liter reaction vessel and heated to 80°C. Initiator A was then added to the reaction vessel, followed by the uniform addition of the monomer premix to the reac...

Embodiment 2

[0046] Emulsion polymer B of methacrylic acid, methyl methacrylate, 2-ethylhexyl acrylate, styrene, diacetone acrylamide and AMPS 2405 was prepared by using phosphate ester surfactants:

[0047] By mixing 216g of water, 45.6g of diacetone acrylamide, 1.07g of ammonium lauryl sulfate (Sipon TM L-22), 0.64g ammonium carbonate, 9.6g nonylphenol ethoxylate phosphate (Dextrol TM OC-110), 4 g methacrylic acid, 453.6 g methyl methacrylate, 88.8 g 2-ethylhexyl acrylate, and 200 g styrene to prepare a monomer premix. Initiator A was prepared by dissolving 0.8 g ammonium persulfate in 13.3 g water. Initiator B was prepared by dissolving 1.2 g of ammonium persulfate in 80 g of water. 592g water, 4.8g Dextrol TM OC-110, 0.72 g ammonium carbonate and 1.91 g 28 wt% ammonium hydroxide were charged into a 3 liter reaction vessel and heated to 80°C. Initiator A was then added to the reaction vessel, followed by the uniform addition of the monomer premix to the reaction vessel over a per...

Embodiment 3

[0049] Preparation of emulsion polymer C of methacrylic acid, methyl methacrylate, 2-ethylhexyl acrylate, styrene, diacetone acrylamide and AMPS 2405 by using phosphate ester surfactants:

[0050] By mixing 216g of water, 45.6g of diacetone acrylamide, 1.07g of ammonium lauryl sulfate (Sipon TM L-22), 0.64g ammonium carbonate, 9.6g tridecyl alcohol ethoxylate phosphate (Dextrol TM OC-40), 4 g methacrylic acid, 453.6 g methyl methacrylate, 88.8 g 2-ethylhexyl acrylate, and 200 g styrene to prepare a monomer premix. Initiator A was prepared by dissolving 0.8 g ammonium persulfate in 13.3 g water. Initiator B was prepared by dissolving 1.2 g of ammonium persulfate in 80 g of water. 592g water, 4.8g Dextrol TM OC-40, 0.72 g ammonium carbonate and 1.91 g 28 wt% ammonium hydroxide were charged to a 3 liter reaction vessel and heated to 80°C. Initiator A was then added to the reaction vessel, followed by the uniform addition of the monomer premix to the reaction vessel over a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com