New method for improving life and stability of glucose oxidase by modifying surface of glucose oxidase with biocompatible polymer

A glucose oxidase, biocompatible technology, applied in a new field of modifying the surface of glucose oxidase with biocompatible polymers to improve its lifespan and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

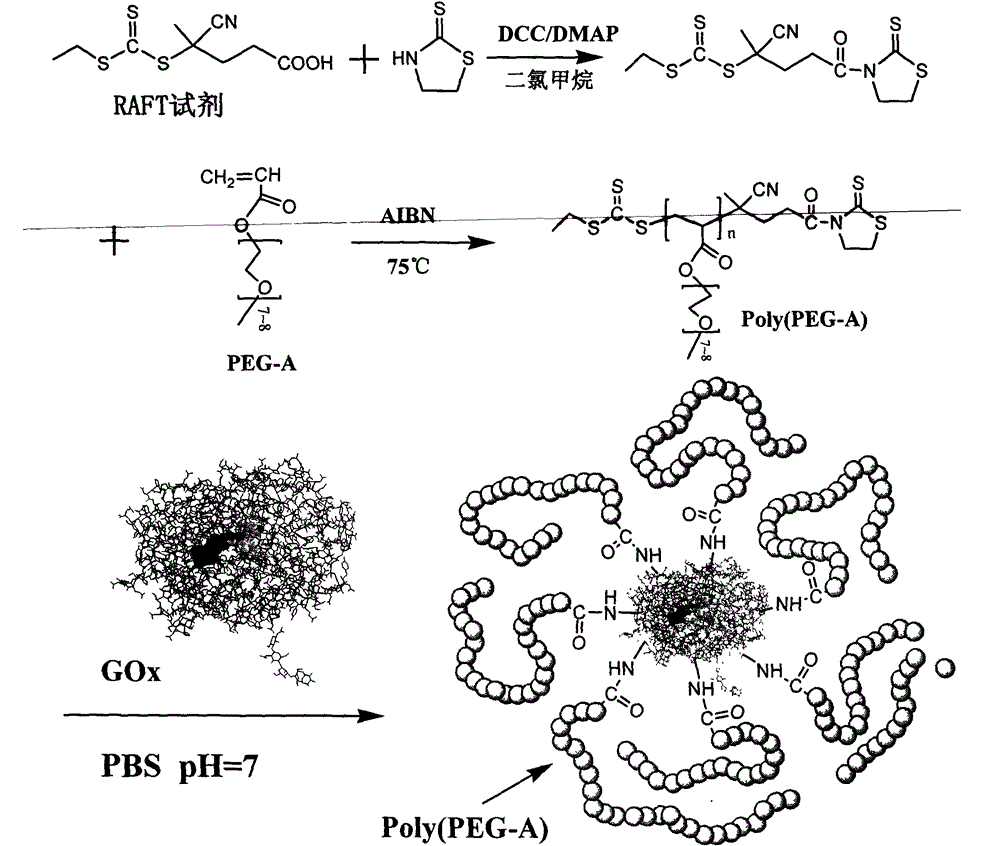

Method used

Image

Examples

Embodiment 1

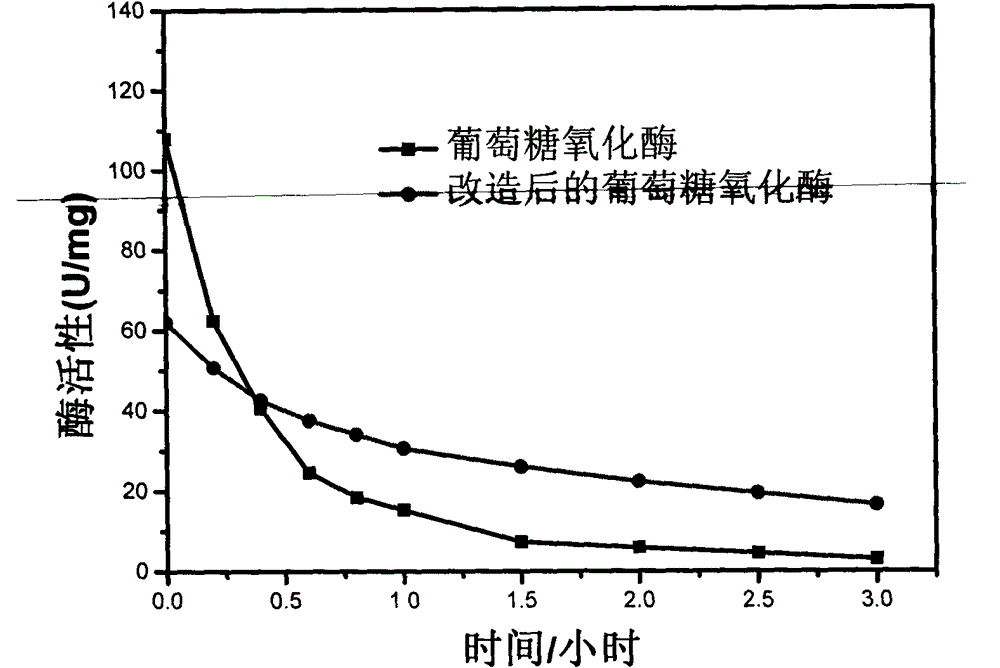

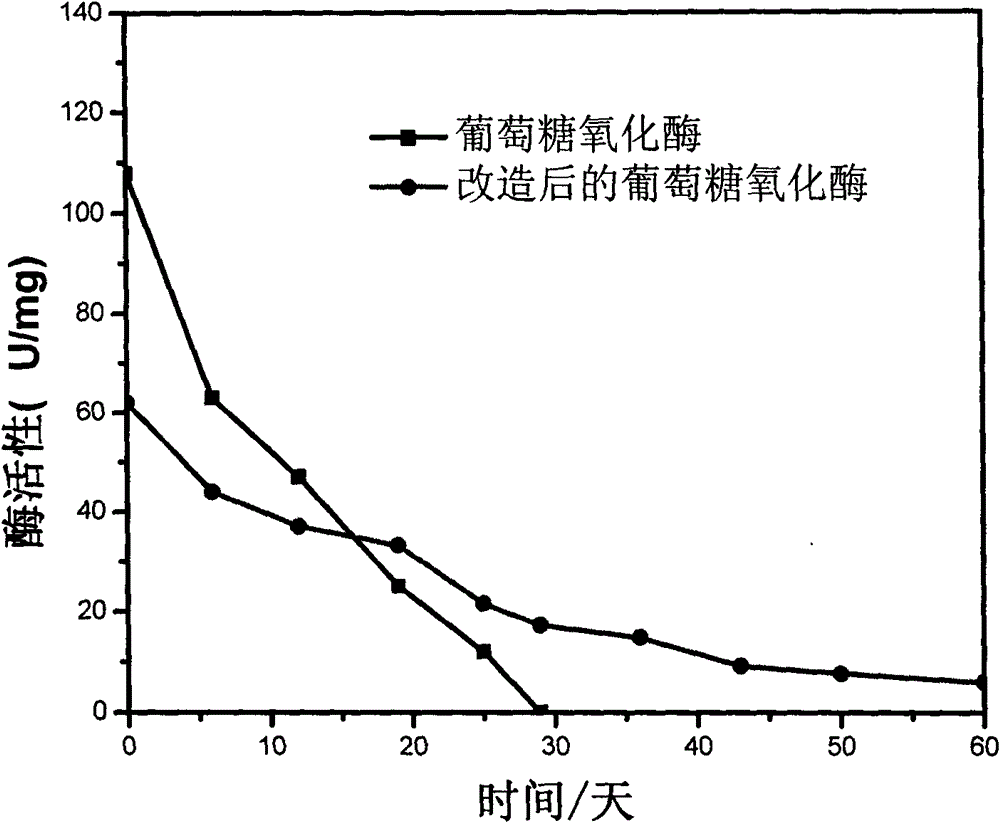

[0014] Embodiment 1. Take RAFT reagent 0.527g, 2-mercaptothiazoline 0.238g, dissolve in the methylene chloride of 10ml. Further, 0.497 g of a dehydrating agent dicyclohexylcarbodiimide (DCC) and 24.5 mg of a catalyst 4-dimethylaminopyridine (DMAP) were added, and stirred at room temperature for 7 hours. After the reaction, the solid particles were removed by suction filtration, and then the product was purified through a silica gel column. 7.6 mg of RAFT reagent with mercaptothiazoline terminal groups, α-(1-oxo-2-propenyl)-ω-methoxypoly(oxyethylene) (PEG-A) 2 g, azobisisobutyl Cyanide (AIBN) 1 mg was dissolved in 4 ml of dioxane, wherein the molar ratio of RAFT reagent to PEG-A was 1:100. Nitrogen gas was used to remove oxygen for 40 minutes, and then the reaction system was sealed and reacted in an oil bath at 75° C. for 5 hours. After the reaction, the polymer was purified by precipitation with ether to obtain the expected product. Add 5 mg of glucose oxidase solution in ...

Embodiment 2

[0015] Example 2. Change the molar ratio in 1 to RAFT reagent: PEG-A=1:50, and others are as in Example 1.

Embodiment 3

[0016] Example 3. Change the molar ratio in 1 to RAFT reagent: PEG-A=1:200, and others are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com