Preparation method of G-quadruplex/heme enzyme/carbon nanotube composite and application of G-quadruplex/heme enzyme/carbon nanotube composite to lithium-sulfur battery

A technology of carbon nanotubes and composite materials, which is applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of low utilization rate of active materials, hindering the process of practical application, corrosion of metal lithium, etc., and achieves easy mass production and inhibition Shuttle effect, solve the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

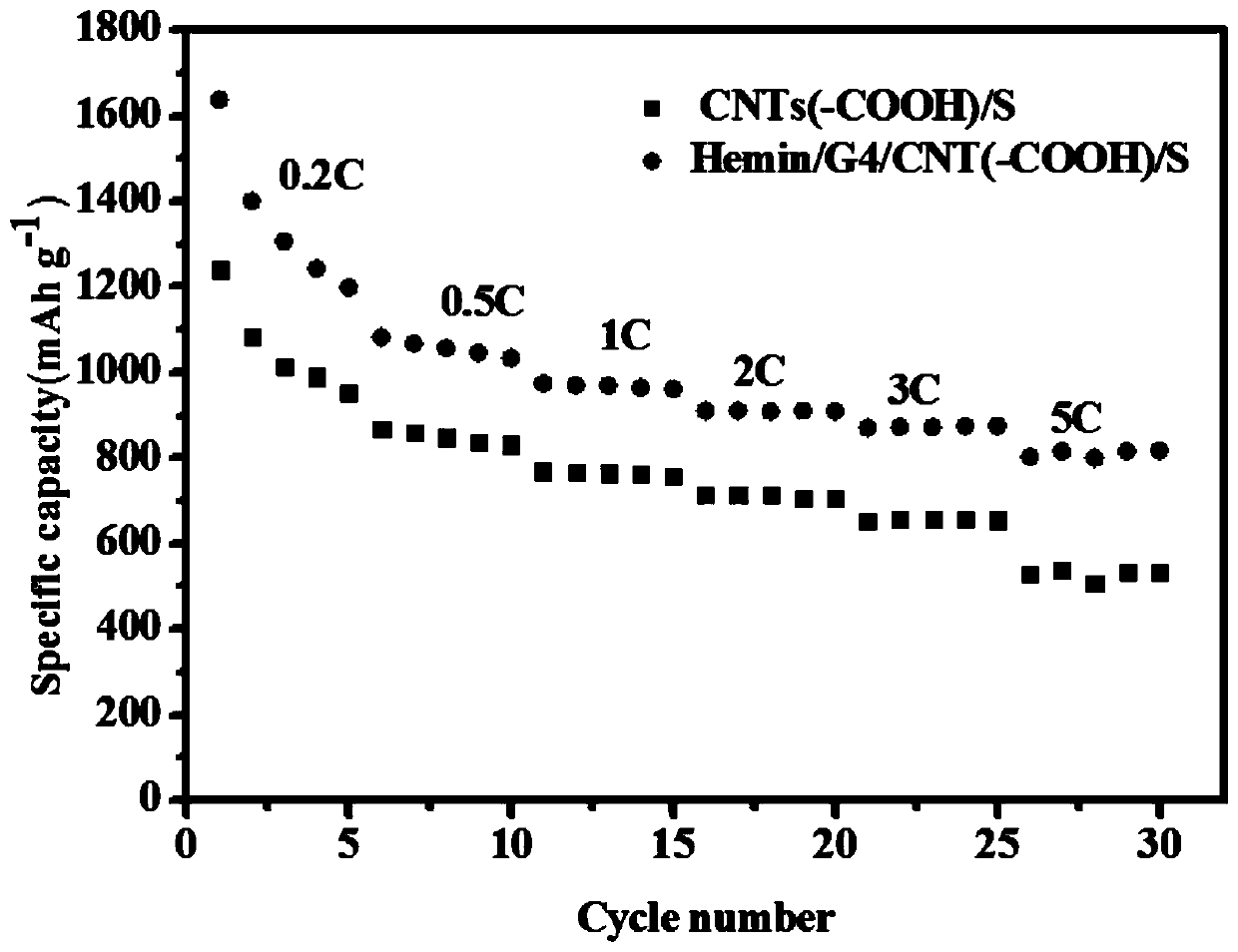

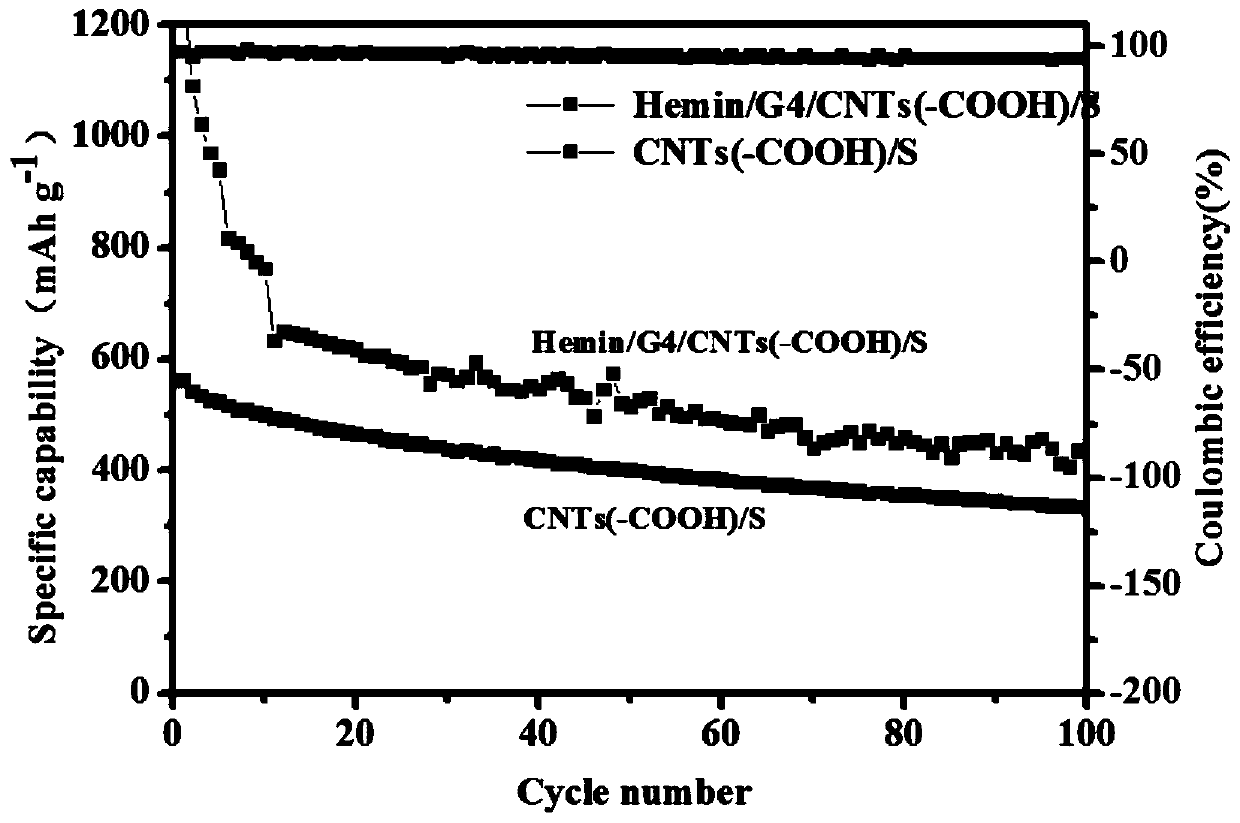

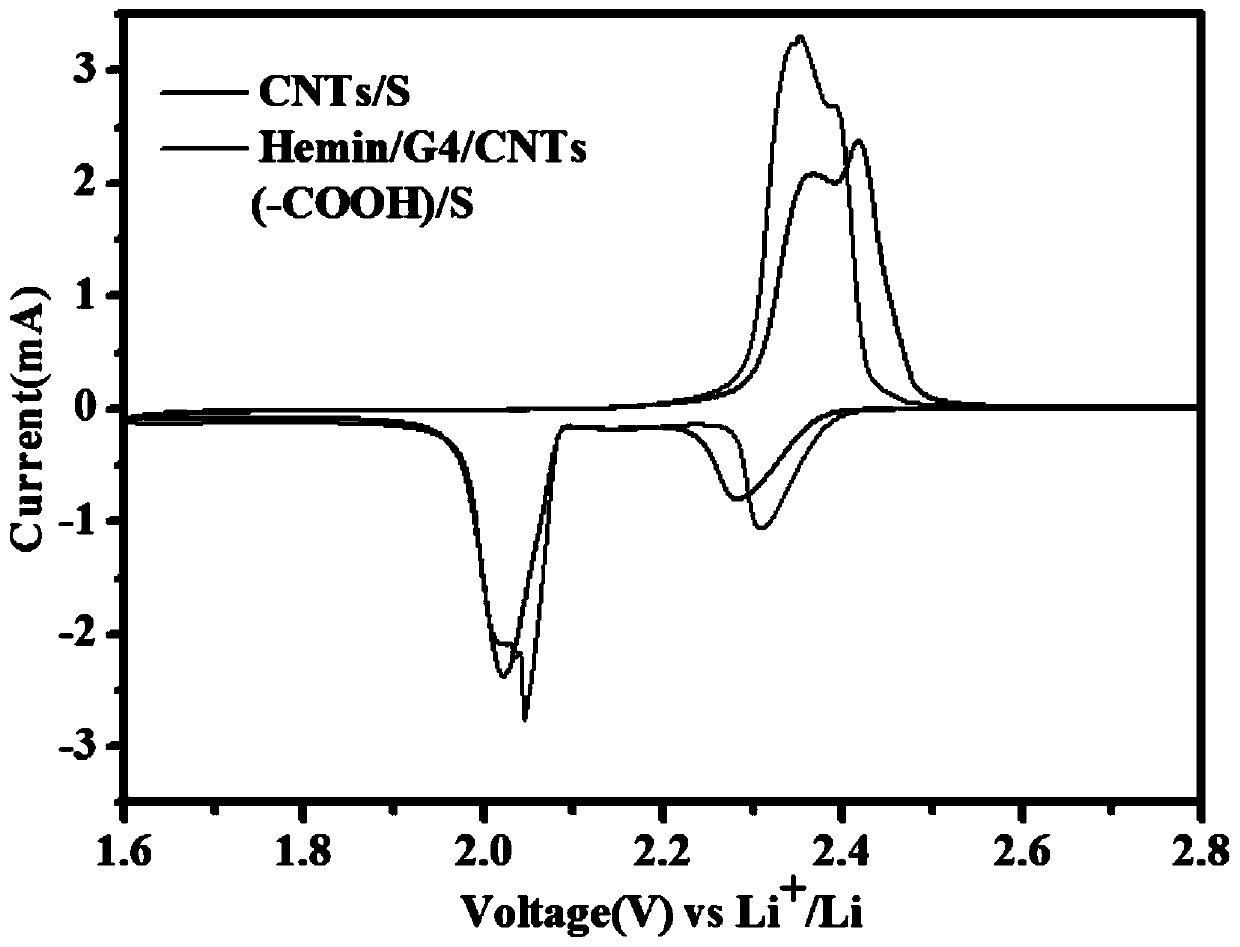

[0042] Example 1: Preparation of Hemin / G4 / carbon nanotube (-COOH) / S cathode material and its application in lithium-sulfur batteries

[0043] (1) Preparation of carboxylated carbon nanotubes:

[0044] 1g CNT (carbon nanotube) and 100ml mixed acid (volume ratio 98%H 2 SO 4 :68%HNO 3 =3:1) Sonicate at 37°C for 2 hours, dilute the obtained black suspension with water to 250ml, filter through a Buchner funnel with a 0.22μmol / L filter membrane, rinse repeatedly until pH ≥ 4.5, and dry at room temperature for later use.

[0045] Weigh 1 g of SWCNT (single-walled carbon nanotube) and dissolve it in 10 ml of phosphate buffer (20 mmol / L, pH 7.0) added with 0.5 wt % sodium cholate surfactant, and sonicate for 2 h. Finally, CNT-COOH with better dispersion is obtained;

[0046] (2) Preparation of CNT-COOH / S composite material: Take 200 mg of the above-mentioned CNT-COOH and 200 mg of elemental sulfur in a mortar, thoroughly grind the porous carbon and sulfur evenly, transfer the resulti...

Embodiment 2

[0052] Example 2: Preparation of Hemin / G4 / carbon nanotube (-OH) / S cathode material and its application in lithium-sulfur batteries

[0053] (1) Preparation of hydroxylated carbon nanotubes:

[0054] Mix concentrated nitric acid and concentrated sulfuric acid at a volume ratio of 1:3, then put the purified carbon nanotubes obtained in step (1) into the mixed solution, heat in a water bath at 50°C for 12 hours for hydroxylation treatment, and then continuously Dilute the solution until the pH reaches 7. Then it is filtered and dried, and ball milled in an agate jar to obtain hydroxylated multi-walled carbon nanotubes;

[0055] (2) Preparation of carbon nanotube (-OH) / S composite material: take 200 mg of the above-mentioned CNT (-OH) and 400 mg of elemental sulfur in a mortar, fully grind the porous carbon and sulfur evenly, transfer the resulting mixture to 25 ml and weigh bottle, and add 6mL CS 2 Stir well, wait until CS 2 After the volatilization is complete, transfer the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com