Hot-rolled coil plate for oil casing and manufacturing method thereof

A technology for oil casing and a manufacturing method, which is applied in the field of hot-rolled coil for oil casing and its manufacturing, and can solve the problems of high carbon content and affecting welding performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

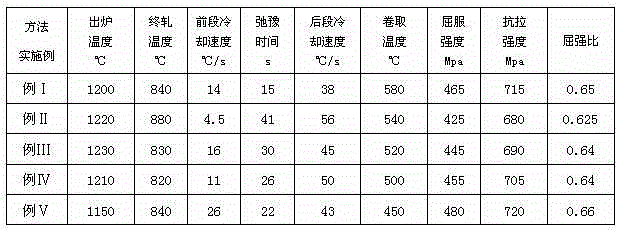

[0107] The specific embodiment of the present invention is described in detail below in conjunction with embodiment, but specific embodiment of the present invention is not limited to following embodiment

[0108] Embodiment 1 of hot-rolled coil

[0109] The technical features of the coiled plate of the present invention will be described in detail below with this embodiment. The mass percent of the chemical composition of the hot-rolled coil for oil casing pipe (K55 steel grade) in this embodiment is:

[0110] C: 0.18 Si: 0.195 Mn: 1.26 P: 0.011 S: 0.002 Al: 0.018

[0111] Nb: 0.018 Ti: 0.014

[0112] The balance is Fe and unavoidable impurity elements.

[0113] The coiled plate of this embodiment has a thickness of 12.2mm, a width of 1600mm, and a length of 193.6m.

[0114] Its tensile strength Rm=715Mpa, yield strength is Rt 0.5 =465Mpa, the yield ratio is 0.65, which meets the performance requirements of K55 oil casing for hot-rolled strip steel.

[0115] Embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com