Elevator-type underground stereo garage shaft and construction method thereof

The technology of a three-dimensional garage and construction method is applied in the field of underground construction engineering to achieve the effects of low cost, improved strength, and excellent public safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

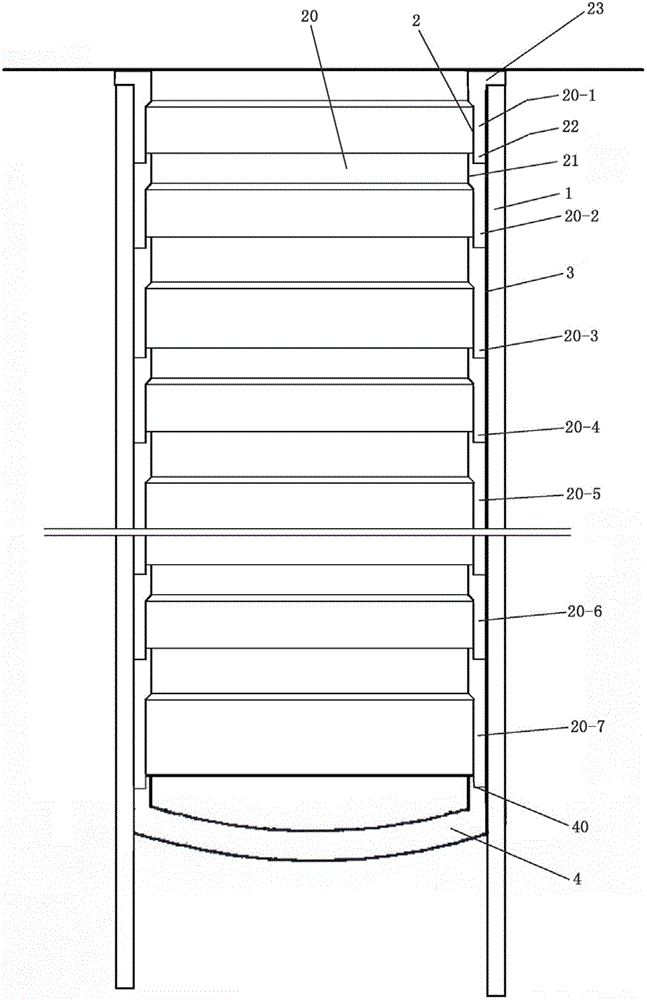

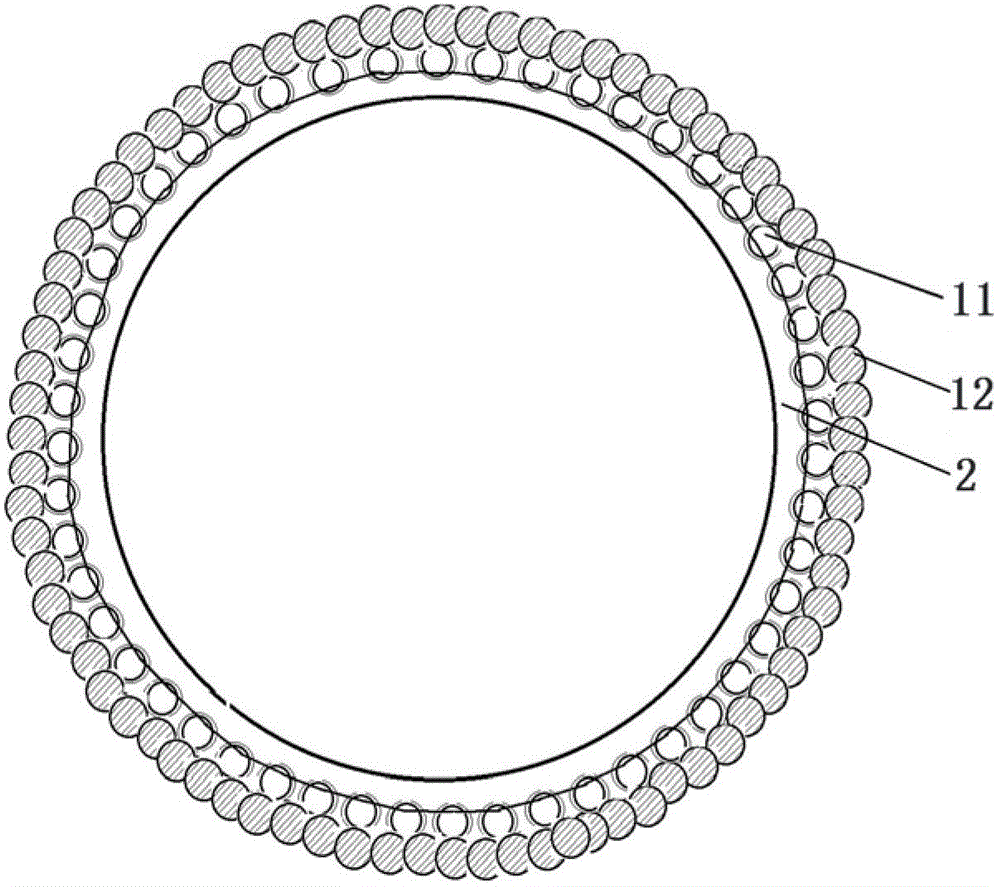

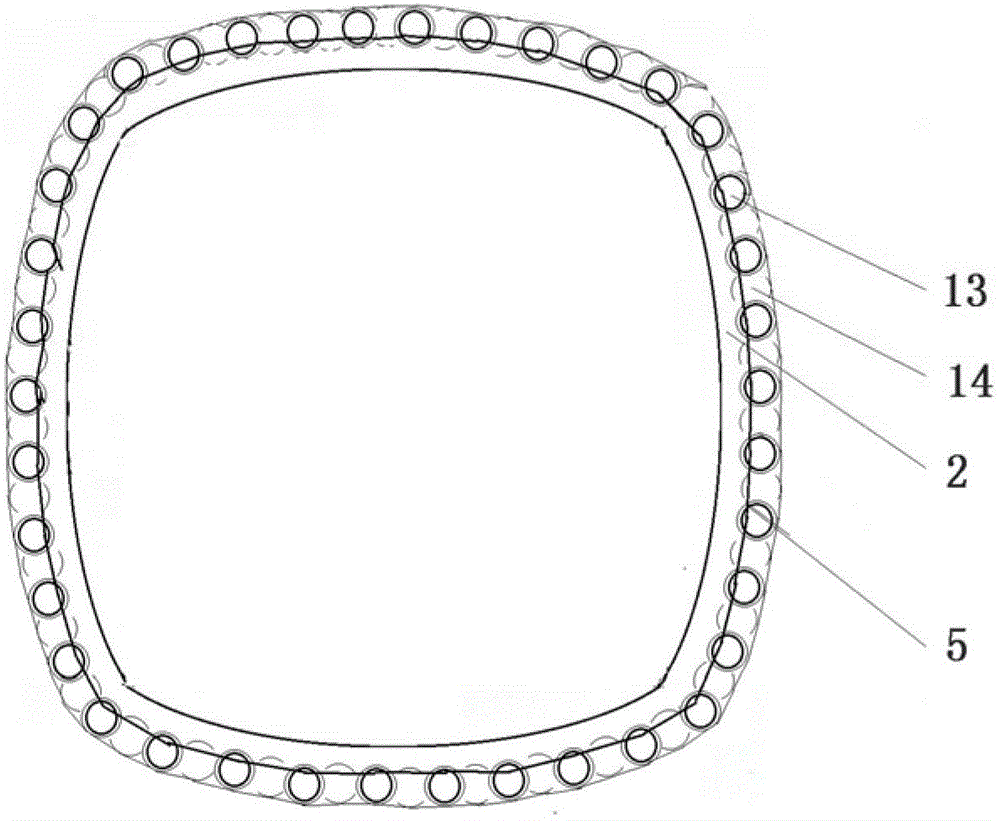

[0038] Refer to attached figure 1. The shaft wall structure of the elevator-type underground three-dimensional garage shaft is a reinforced concrete composite shaft wall, which is composed of a reinforced concrete inner shaft wall 2 and a reinforced concrete outer shaft wall 1, the outer shaft wall is composed of piles or underground continuous walls, and the inner surface of the outer shaft wall It is chiseled until its steel bars are exposed, and the steel bars on the inner well wall and the outer well wall are welded and / or bound together, the inner well wall is on the inner side of the outer well wall, and the inner well wall is formed by pouring in multiple sections from top to bottom; In this embodiment, the multiple sections are respectively represented by the following symbols 20-1, 20-2, 20-3, 20-4, 20-5, 20-6, 20-7; The upper end 21 of that section presses out the lower end 22 of the section above and forms in this area a ring-shaped convex transverse structural sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com