Energy-saving control method for heating furnace hydraulic system

A hydraulic system, energy-saving control technology, applied in the direction of furnace control devices, lighting and heating equipment, furnaces, etc., can solve the problems of high investment, difficult to control oil temperature, high energy consumption, etc., achieve simple control methods, reduce energy consumption, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

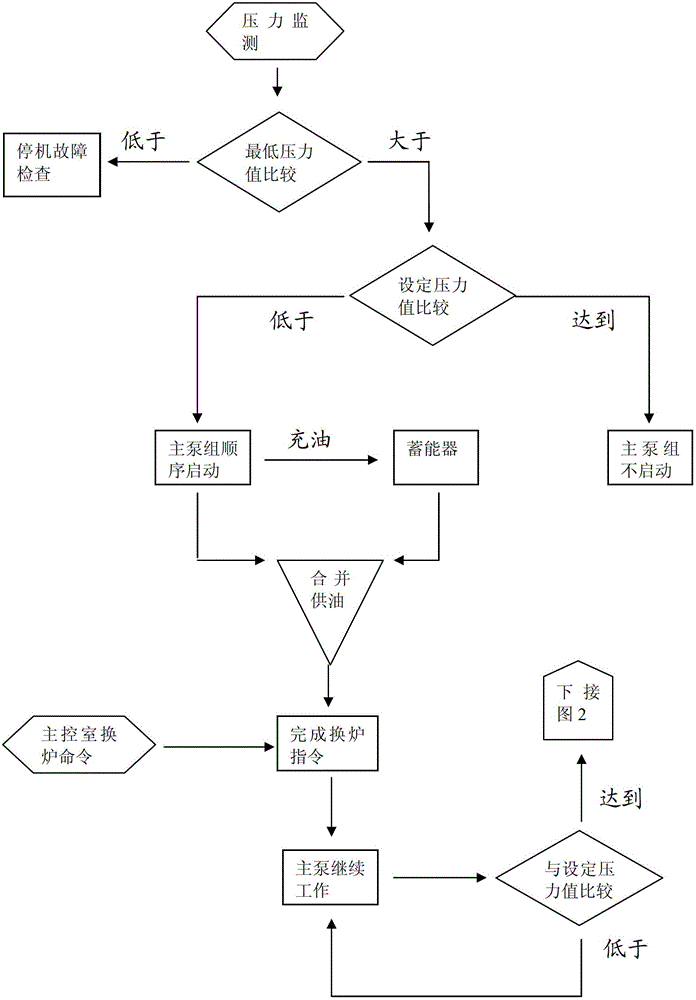

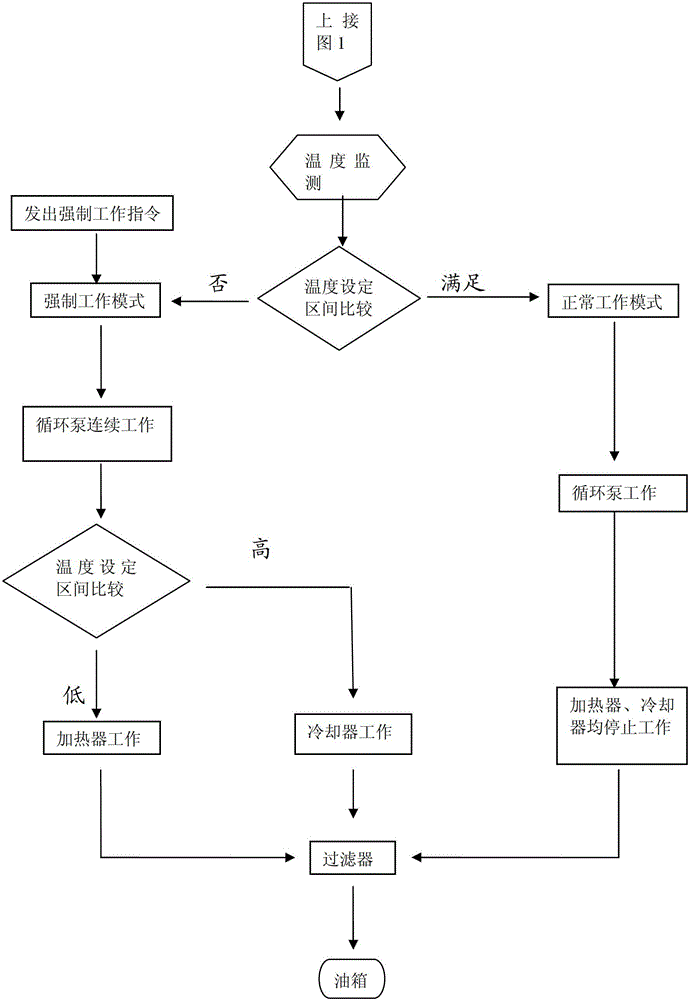

[0023] In the energy-saving control process of the heating furnace hydraulic system in the present invention, the circulating pump group and the main pump group are alternately operated, and the accumulator is involved in the hydraulic power output of the furnace replacement operation, so that the circulating pump group and the main pump group have Part of the time is in sleep and energy-saving state, and the specific control steps are as follows:

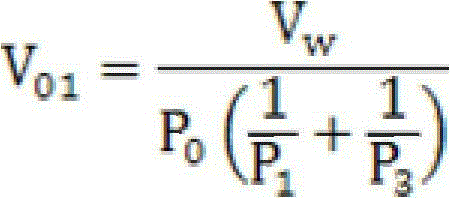

[0024] 1) see figure 1 , before the furnace replacement operation, the pressure status of the hydraulic system is monitored in real time online. When the system pressure is higher than the set value, the main pump unit does not start and is in a dormant state; when the system pressure is lower than the set value, the main pump unit starts sequentially. The accumulator supplies oil, and the setting val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com