Miniature eddy current sensor with structure consisting of silicon substrate and multilayer coils

An eddy current sensor and multi-layer coil technology, applied in the field of micro-sensors, can solve the problems of increasing preparation time, prolonging the detection period, and large human radiation, so as to increase the area of flaw detection, improve the detection efficiency, and increase the detection area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

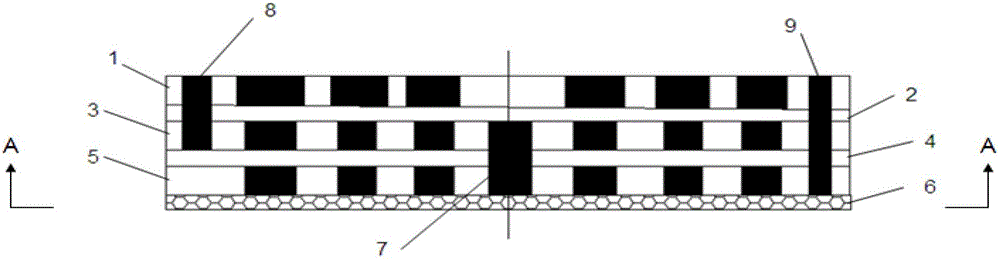

[0025] Specific embodiments of the present invention will be described in detail in conjunction with the accompanying drawings

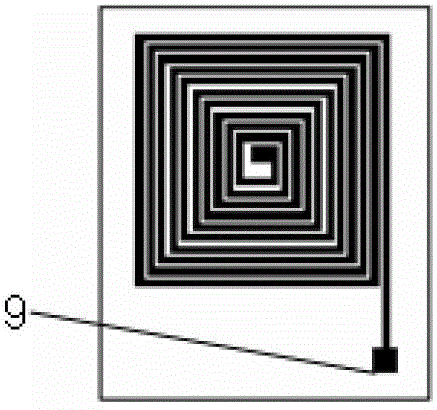

[0026] The inductance coil structure of the micro sensor of the present invention is based on the comparison of self-inductance and mutual inductance. Considering that the inductance coil in the self-inductance structure acts as an excitation and a detection coil at the same time, the signal-to-noise ratio is small in practical applications, so the present invention Select the mutual inductance structure, that is, the sensor is composed of independent detection coils and excitation coils. The alternating current generated by the signal source is applied to the excitation coil, and the generated alternating electric field makes the surface of the workpiece under test in an alternating magnetic field, thereby inducing eddy currents; the adjacent detection coils form a reverse spiral, and pass between the coils The wire columns are connected in series, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com