Application of solid phase microextraction in content analysis of naphthalene in Corex furnace gas

An extraction method, gas technology, applied in the application field of solid-phase microextraction in the analysis of Nai content, to achieve the effect of wide application prospects, shortened analysis time, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention proposes the application of the solid-phase microextraction method in the analysis of naphthalene content in Corex furnace gas.

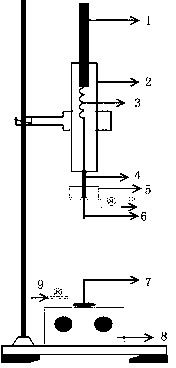

[0024] In the present invention, the extraction head of the solid-phase extraction capillary fiber is inserted into the sampling bottle to extract the naphthalene in the concentrated gas, and then the fiber is injected into the gas phase analyzer for analysis. figure 1 is the analysis device, wherein 1 is a telescopic rod; 2 is a handle; 3 is a spring; 4 is a stainless steel needle; 5 is a sealing plug with a silicone membrane; Air port; 10 is an air outlet.

[0025] Specific steps are as follows:

[0026] Instruments and operating conditions

[0027] Instrument: solid-phase microextraction device: solid-phase microextraction manual injection device (Supelco Company), 100 μm polydimethylsiloxane (PDMS) extraction head (Supelco Company), heat-collecting constant temperature magnetic stirrer (Corning, PC -420d), self-made 40ml ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com