Blackberry seed oil microcapsule and preparation method thereof

A blackberry seed and microcapsule technology, which is applied in the fields of edible oil/fat, food science, application, etc., can solve the problem that the blackberry seed oil microcapsule is still blank, etc., and achieves the effect of not being easily oxidized and deteriorating and overcoming cohesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

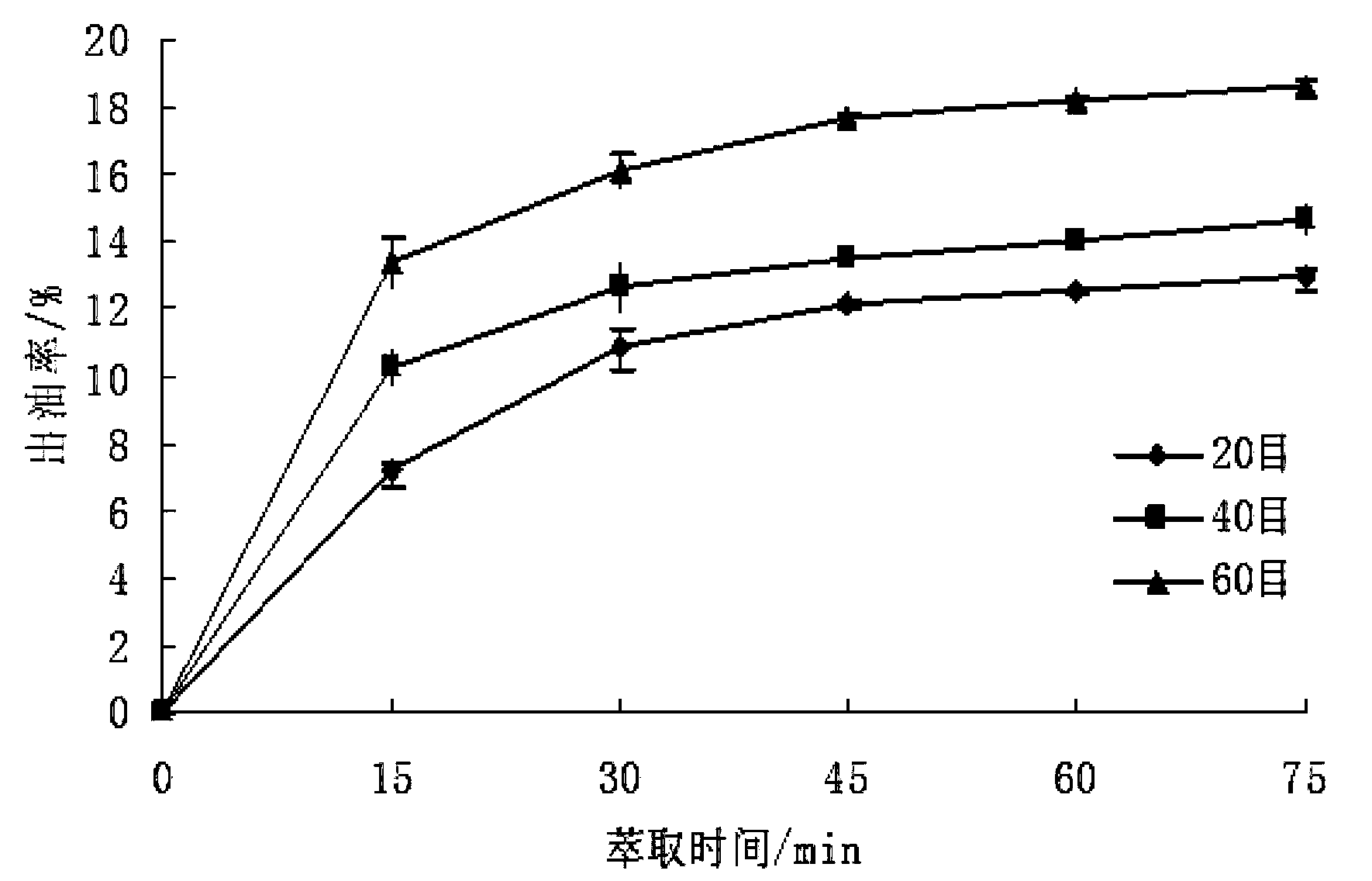

[0032] Determination of Embodiment 1 Freeze Pulverization Degree

[0033] The supercritical extraction conditions are 100g of material, extraction pressure of 30MPa, extraction temperature of 45°C, CO 2 The flow rate was 25L / h, the extraction time was 60min, the separation pressure was 7MPa, and the separation temperature was 35°C. The effects of different crushing degrees (20 mesh, 40 mesh, and 60 mesh) on the oil yield of blackberry seeds were investigated respectively. The oil yield of blackberry seeds showed a gradual increase trend. However, it was found in the experiment that if the crushing degree is greater than 60 mesh, the too fine material will 2 The fluid enters the pipeline through the filter screen and causes pipe blockage, which is not conducive to the use and maintenance of the instrument. Considering comprehensively, the crushing degree of blackberry seeds is preferably 40-60 mesh, and 60 mesh is the best.

Embodiment 2

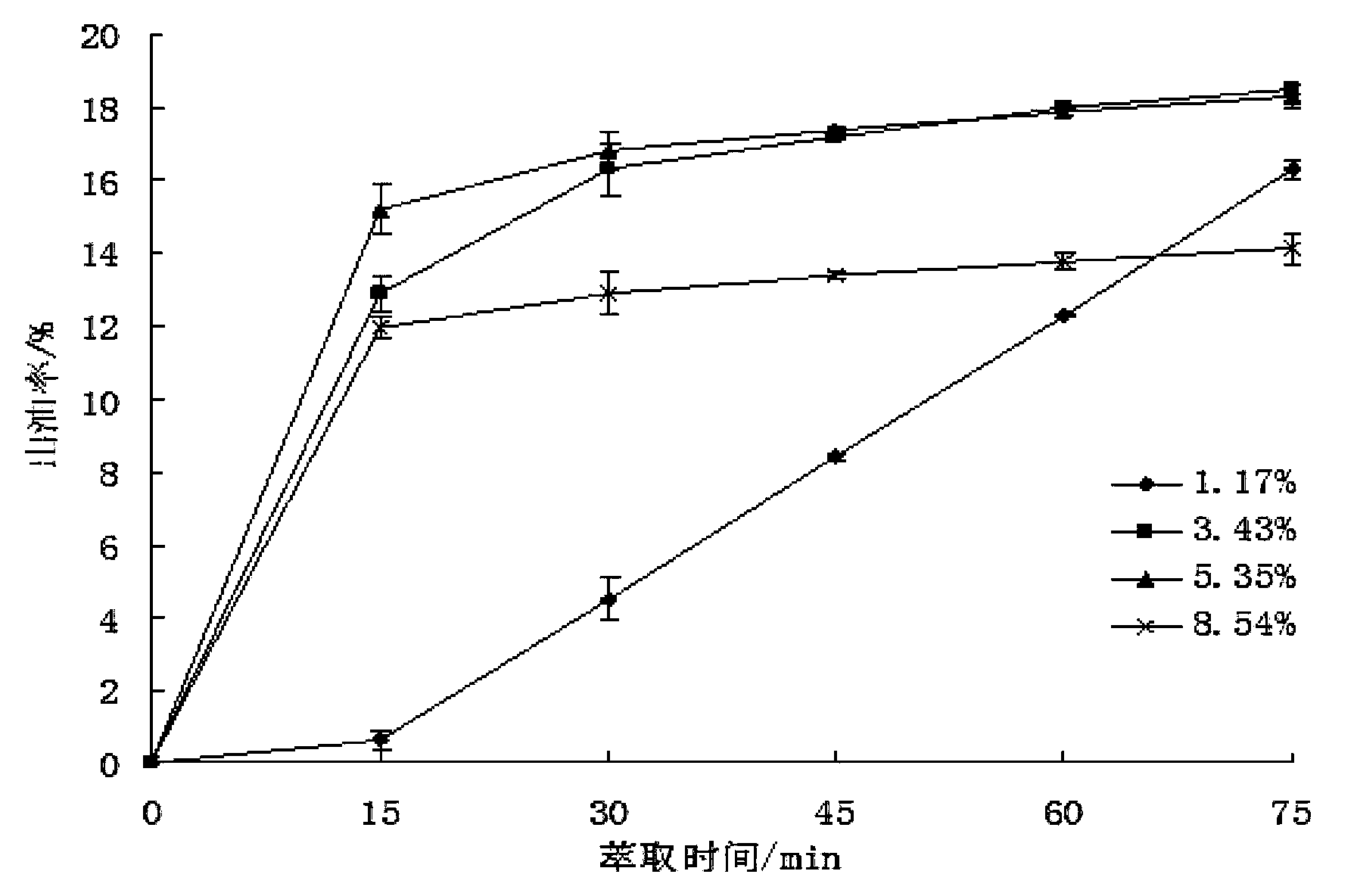

[0034] The determination of embodiment 2 vacuum freeze-drying degree

[0035] The supercritical extraction conditions are 100g of material, extraction pressure of 30MPa, extraction temperature of 45°C, CO 2 The flow rate is 25L / h, the extraction time is 60min, the separation pressure is 7MPa, and the separation temperature is 35°C. The effects of different water contents (1.17%, 3.43%, 5.35%, and 8.54%) on the oil yield of blackberry seeds are respectively investigated. It can be seen from the results When the water content of blackberry seeds was in the range of 1.17%-8.54%, the oil yield of blackberry seed oil increased first and then decreased. When the water content was 3.43%-5.35%, the oil yield was significantly higher than that of other water contents (p< 0.05). And when the moisture content of blackberry seeds is too high, the phenomenon of "ice blockage" is prone to occur, and the extracted oil is turbid and darkened in color. Therefore, the water content of blackbe...

Embodiment 3

[0036] The determination of embodiment 3 supercritical extraction conditions

[0037] Oil yield is the evaluation of supercritical CO 2 An important indicator of the efficiency of extracting blackberry seed oil, and the extraction pressure, extraction temperature, CO 2 The flow rate is affected by the supercritical CO 2 Significant conditions for oil yield in extraction of blackberry seed oil. Therefore the present invention selects extraction pressure, extraction temperature, CO 2 The three flow factors are the independent variables of the Box-Behnken design, and the oil yield rate of blackberry seed oil is used as the response value. Design expert 8 data processing software is used for response surface analysis to optimize the extraction conditions. The experimental design results of the response surface optimization experiments are shown in Table 2.

[0038] Table 2 Box-Behnken design test results

[0039]

[0040]Using Design-Expert 8 software to carry out regressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com