Rifampicin antituberculosis drug compound preparation and preparation method thereof

An anti-tuberculosis drug, rifampicin technology, applied in the field of medicine, can solve problems such as rifampicin instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] Example 1 Rifampicin, isoniazid, pyrazinamide and ethambutol hydrochloride bilayer tablet

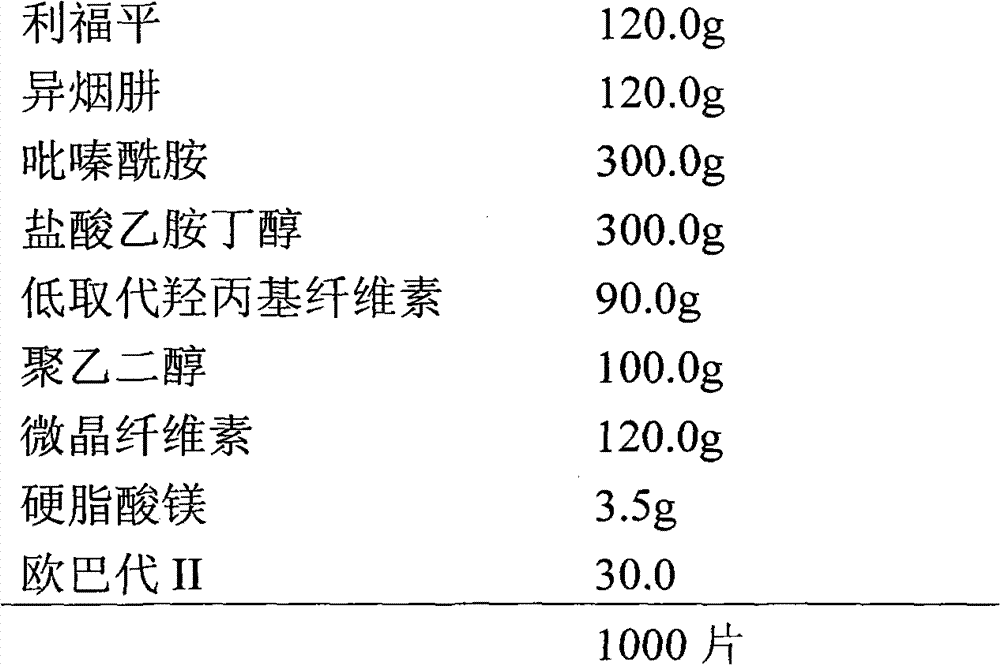

[0025] prescription:

[0026]

[0027] Preparation of double-layer tablet: pass rifampicin alone through a 100-mesh sieve, and perform hot-melt granulation with polyethylene glycol 6000 to obtain dry granules A; pass pyrazinamide, isoniazid and ethambutol hydrochloride through a 80-mesh sieve screen. Mix pyrazinamide, isoniazid, ethambutol hydrochloride, microcrystalline cellulose, 2 / 3 prescription amount of low-substituted hydroxypropyl cellulose and 1 / 2 prescription amount of magnesium stearate, and dry Granules, whole grains, get Granule B. Then mix 1 / 6 of the prescription amount of low-substituted hydroxypropyl cellulose with granule A evenly, and then mix 1 / 6 of the prescription amount of low-substituted hydroxypropyl cellulose with 1 / 2 of the prescription amount of magnesium stearate and granule B Mix evenly, and use a double-layer tablet press machine to compress the...

example 2

[0033] Example 2 Rifampicin, Isoniazid, Pyrazinamide and Ethambutol Hydrochloride Bilayer Tablet

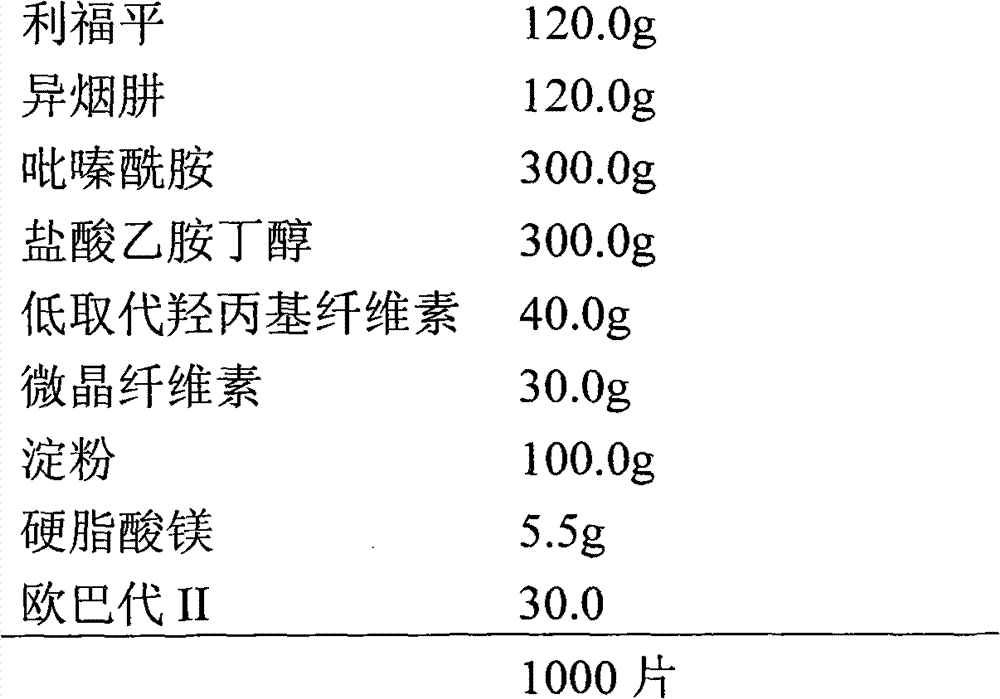

[0034] prescription:

[0035]

[0036] Preparation of double-layer tablets: pass rifampicin alone through a 100-mesh sieve, mix evenly with 2 / 3 of the prescription amount of low-substituted hydroxypropyl cellulose and microcrystalline cellulose, and granulate by dry granulation technology to obtain granule A; Pass pyrazinamide, isoniazid and ethambutol hydrochloride through a 80-mesh sieve, mix evenly with the starch of the prescription amount, add 5% starch slurry to prepare a soft material, pass through a 16-mesh nylon sieve to prepare wet granules, and place in an oven (about 55°C) and ventilated and dried, and then sized with a 16-mesh nylon sieve to obtain Granule B. Then mix the remaining 1 / 3 of the prescription amount of low-substituted hydroxypropyl cellulose with 1 / 3 of the prescription amount of magnesium stearate and granule A, and then mix 2 / 3 of the prescription ...

example 3

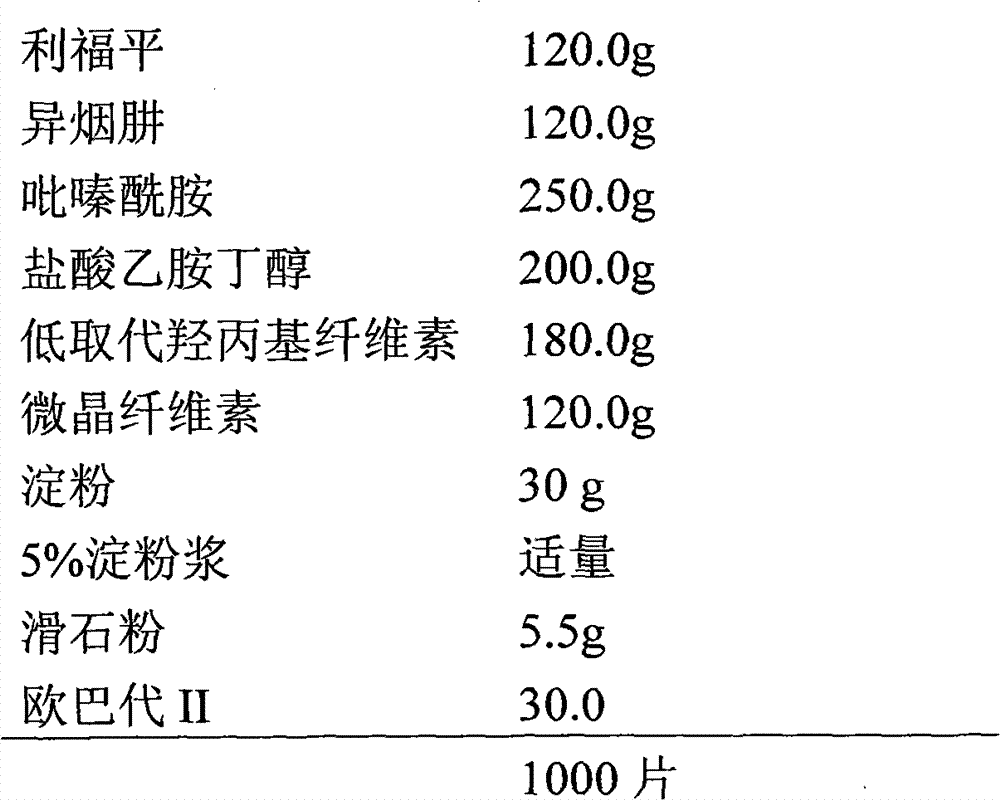

[0041] Example 3 Three-layer tablet of rifampicin, isoniazid, pyrazinamide and ethambutol hydrochloride

[0042]

[0043] Preparation of three-layer tablet: pass rifampicin alone through a 100-mesh sieve, mix evenly with 1 / 3 of the prescription amount of low-substituted hydroxypropyl cellulose and 1 / 3 of the prescription amount of microcrystalline cellulose, and use dry granulation technology to prepare Granules to obtain Granule A; Pyrazinamide, ethambutol hydrochloride, and isoniazid were passed through an 80-mesh sieve, and isoniazid, ethambutol hydrochloride, 2 / 3 of the prescription amount of microcrystalline cellulose and 2 / 3 The low-substituted hydroxypropyl cellulose in the prescribed amount was mixed evenly, and granulated by dry granulation technology to obtain granule B. Mix pyrazinamide with the prescribed amount of starch evenly, add 5% starch slurry to prepare soft materials, pass through a 16-mesh nylon sieve to prepare wet granules, put them in an oven (about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com