Optimization structure based on inverter welding machine main circuit

A technology of inverter welding machine and optimized structure, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as IGBT module overvoltage failure, achieve the effect of reducing wire length, reducing inductance, and optimizing layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

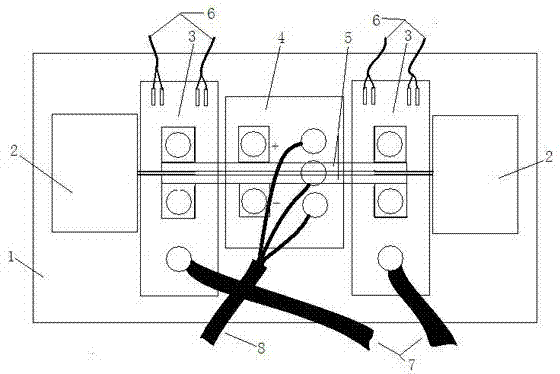

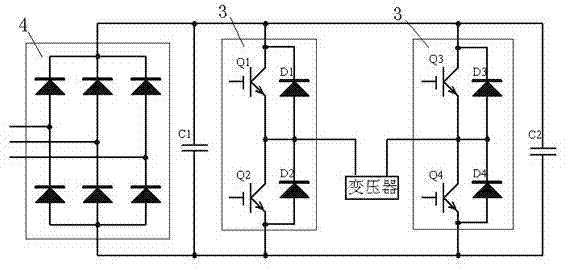

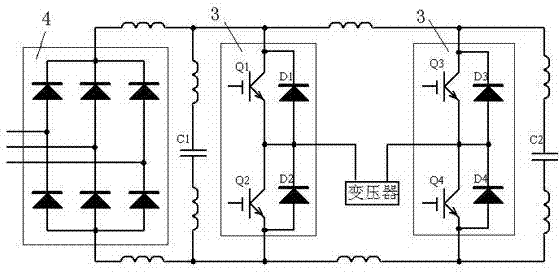

[0017] As shown in the figure, the present invention includes a main circuit, which includes a snubber capacitor 2 , two IGBT modules 3 , a rectifier module 4 , a low-inductance busbar 5 and a gate drive line 6 . Snubber capacitor 2, two IGBT modules 3, rectifier module 4, and low-inductance busbar 5 are placed on the heat sink 1 in a compact structure, and the snubber capacitor 2 is directly connected to the IGBT module 3 by its pins to ensure that the snubber capacitor is connected to the circuit Shortest effect for optimal absorption. The two IGBT modules 3 and the rectifier module 4 are directly connected by a low-inductance busbar 5, which ensures the shortest connection distance and reduces parasitic inductance. The gate drive line 6 uses a twisted pair; the lead wire 7 is drawn from one side of the transformer. The input leads 8 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com