Composite rubber film for pipe sealing rings and preparation method thereof

A compound rubber and pipeline sealing technology, applied in the polymer field, can solve the problems of difficult installation, large compression set, and larger size of the sealing ring, so as to reduce the possibility of mechanical damage, small compression set, and mechanical strength. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

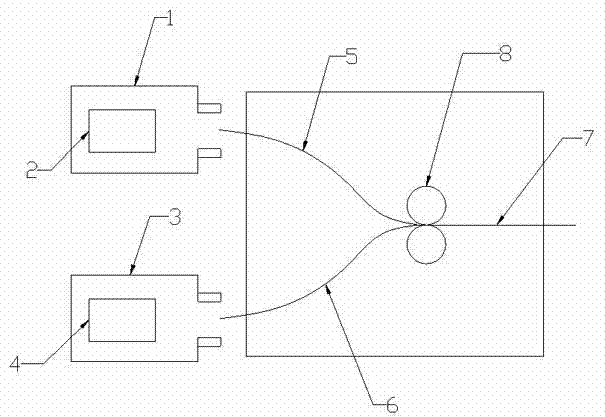

[0020] see figure 1 , add natural rubber in A material storage box 2, add the mass percentage content and be 75% acrylic acid and 25% natural rubber in B material storage box 4, control the extrusion of A preforming machine 1 and B preforming machine 3 The output speed is 50r / min, the temperature of the head of A preforming machine 1 is controlled at 50°C, the temperature of the head of B preforming machine 3 is controlled at 60°C, and the A preforming machine 1 extrudes 600mm wide and 10-15mm thick Elastic rubber film 5, B preforming machine 3 extrudes a water-swellable material film 6 with a width of 600mm and a thickness of 10-15mm, and then places the extruded film on two conveyor belts, and the conveying speed of the conveyor belt matches the preforming The extrusion speed of the machine. The elastic rubber film 5 on the conveyor belt and the water-swellable material film 6 are pasted together by hand, and then put into the bonding roller 8 for heat vulcanization and pr...

Embodiment 2

[0022] see figure 1 , add natural rubber in A material storage box 2, add mass percentage content to be 68% methacrylic acid and 32% natural rubber in B material storage box 4, control A preforming machine 1 and B preforming machine 3 The extrusion speed is 50r / min, the head temperature of A preforming machine 1 is controlled at 55°C, the head temperature of B preforming machine 3 is controlled at 65°C, and the A preforming machine 1 extrudes a width of 600mm and a thickness of 10- 15mm elastic rubber film 5, B preforming machine 3 extrudes a water-swellable material film 6 with a width of 600mm and a thickness of 10-15mm, and then places the extruded film on two conveyor belts, and the conveying speed of the conveyor belt matches The extrusion speed of the preformer. The elastic rubber film 5 on the conveyor belt and the water-swellable material film 6 are pasted together by hand, and then put into the bonding roller 8 for heat vulcanization and pressing to form a composite ...

Embodiment 3

[0024] see figure 1 , add natural rubber in A material storage box 2, add mass percent acrylamide and 30% natural rubber in B material storage box 4, control A preforming machine 1 and B preforming machine 3 The extrusion speed is 55r / min, the head temperature of A preforming machine 1 is controlled at 60°C, the temperature of the head of B preforming machine 3 is controlled at 65°C, and the extrusion width of A preforming machine 1 is 600mm and the thickness is 10-15mm. The elastic rubber film 5, the B preforming machine 3 extrudes the water-swellable material film 6 with a width of 600 mm and a thickness of 10-15 mm, and then places the extruded films on two conveyor belts respectively. The extrusion speed of the molding machine. The elastic rubber film 5 on the conveyor belt and the water-swellable material film 6 are pasted together by hand, and then put into the bonding roller 8 for heat vulcanization and pressing to form a composite rubber film 7. The rotating speed ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com