Preparation method for sensitization-enhanced green light-emitting high-silica glass

The technology of high silica glass and borosilicate glass is applied in the field of preparation of sensitized and enhanced green light-emitting high silica glass, which can solve the problems of few light sources, harm to human body, and insufficient luminous intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

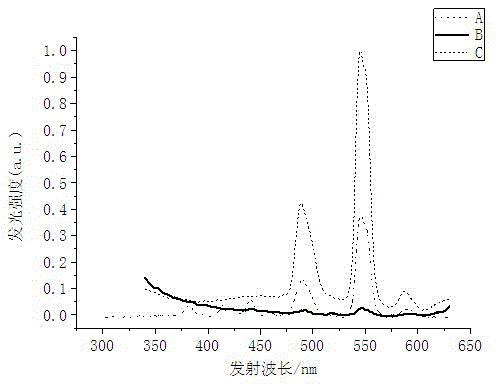

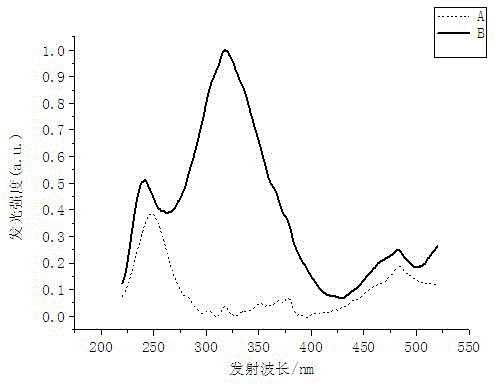

Examples

Embodiment 1

[0026] Take analytically pure chemical reagents, according to SiO 2 63.72mol%, Na 2 CO 3 9.80 mol%, H 3 BO 3 The ratio of 26.48 mol % is used to prepare mixed raw materials. After mixing and grinding evenly, put it into a platinum crucible, and after melting at a high temperature of 1450°C for 40 minutes, cool it on an iron plate at 400°C to form borosilicate glass.

[0027] Put the borosilicate glass into a high-temperature furnace and heat-treat at 590° C. for 20 hours, and then cut it into glass pieces of 5 mm×5 mm×1 mm. Put the glass into a sealed autoclave, and place it at 98°C for three times of 24-hour acid treatment; for the first time, immerse it in a 1mol / L nitric acid solution at a ratio of 50ml acid solution / gram of glass, and for the second time Immerse in 1mol / L nitric acid solution at the ratio of 10ml acid solution / gram of glass, and immerse in 0.3mol / L nitric acid solution at the ratio of 10ml acid solution / gram glass for the third time. Then the glas...

Embodiment 2

[0032] Take analytically pure chemical reagents, according to SiO 2 52.07mol%, Na 2 CO 3 5.82 mol%, H 3 BO 3 39.17 mol %, Al(OH) 3 The ratio of 2.94mol% is used to prepare mixed raw materials. After mixing and grinding evenly, put it into a corundum crucible, and after melting at 1400°C for 60 minutes, cool it on an iron plate at 300°C to form borosilicate glass.

[0033] Put the borosilicate glass into a high-temperature furnace and heat-treat at 560° C. for 40 hours, and then cut it into glass pieces of 5 mm×5 mm×1 mm. Put the glass into a sealed autoclave, and place it at 90°C for three times of 12-hour acid treatment; for the first time, immerse it in 1mol / L hydrochloric acid solution at a ratio of 50ml acid solution / gram of glass, and for the second time Immerse in 1mol / L hydrochloric acid solution three times at the ratio of 10ml acid solution / gram glass. Then the glass is taken out from the autoclave, washed with distilled water, and dried to obtain a high-si...

Embodiment 3

[0036] Take analytically pure chemical reagents, according to SiO 2 62.81mol%, Na 2 CO 3 10.15 mol%, H 3 BO 3 The ratio of 27.04 mol % is used to prepare mixed raw materials. After mixing and grinding evenly, put it into a corundum crucible, and after melting at 1500°C for 30 minutes, cool it on an iron plate at 200°C to form borosilicate glass.

[0037] Put the borosilicate glass into a high-temperature furnace and heat-treat at 630° C. for 10 hours, and then cut it into glass pieces of 5 mm×5 mm×1 mm. Put the glass into a sealed autoclave, immerse it in a 1mol / L nitric acid solution at a ratio of 50ml acid solution / gram of glass, and place it at 100°C for a 48-hour acid treatment. Then the glass is taken out from the autoclave, washed with distilled water, and dried to obtain porous glass.

[0038] Use Tb 4 o 7 and Eu(NO 3 ) 3 Prepare a mixed solution containing 0.01mol / L Tb ion and 0.01mol / L Eu ion with nitric acid solution. Soak the aforementioned high-silica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com