A carborane-like covalent organic framework material modified separator and lithium-sulfur battery

A technology of covalent organic framework and lithium-sulfur battery, which is applied in the direction of lithium storage battery, battery pack components, non-aqueous electrolyte storage battery, etc. It can solve the problems of low efficiency and achieve low density, simple coating process and good thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

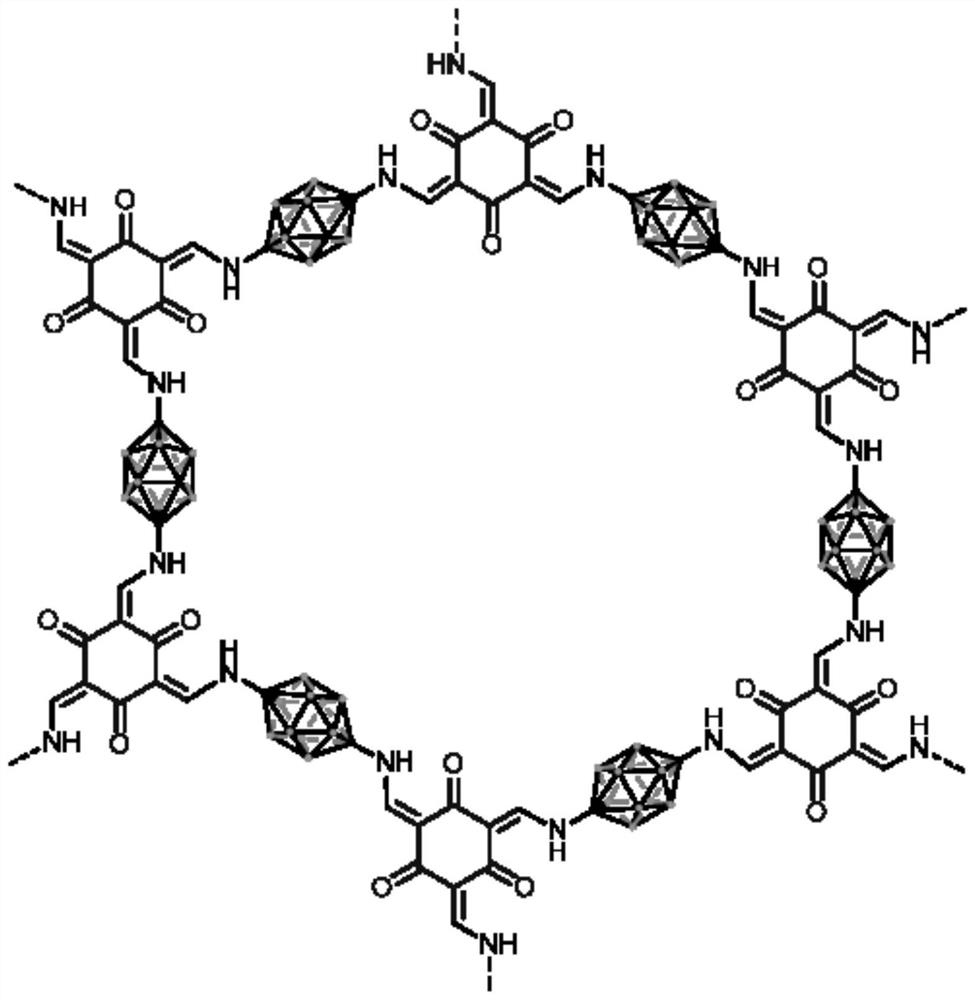

[0041] 1. Preparation of a novel separator containing p-carborane covalent organic framework materials

[0042] 1) Under the protection of nitrogen, dissolve 500mg p-carborane in 9.0ml anhydrous tetrahydrofuran, and cool to 0°C, add dropwise 4.56ml n-butyllithium, stir at room temperature for 2 hours, cool to 0°C again, add 800 μl of phenyl azide, the mixture was stirred at room temperature for 12 hours and then pumped dry, ether and saturated ammonium chloride solution were added, the organic phase was collected, washed three times with saturated brine, and the ether was concentrated to obtain substance I with a yield of 86%.

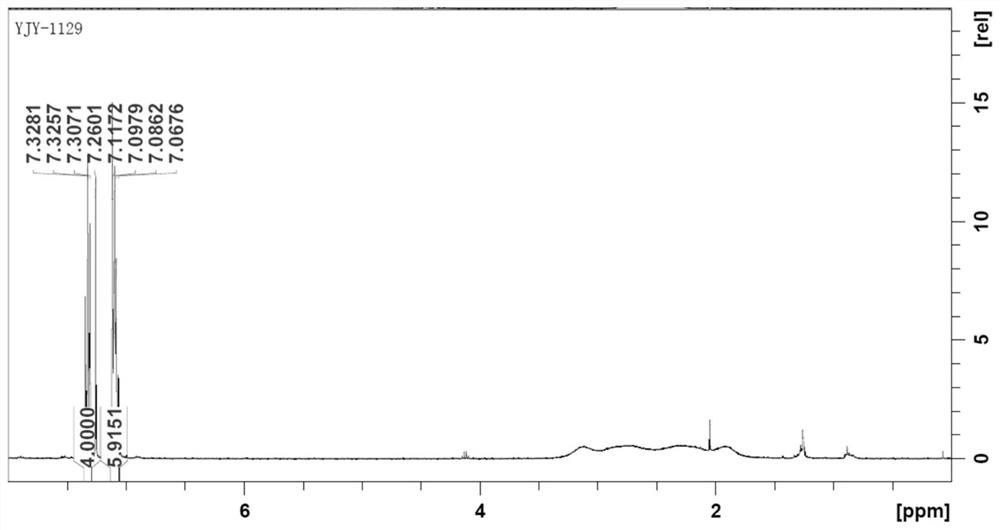

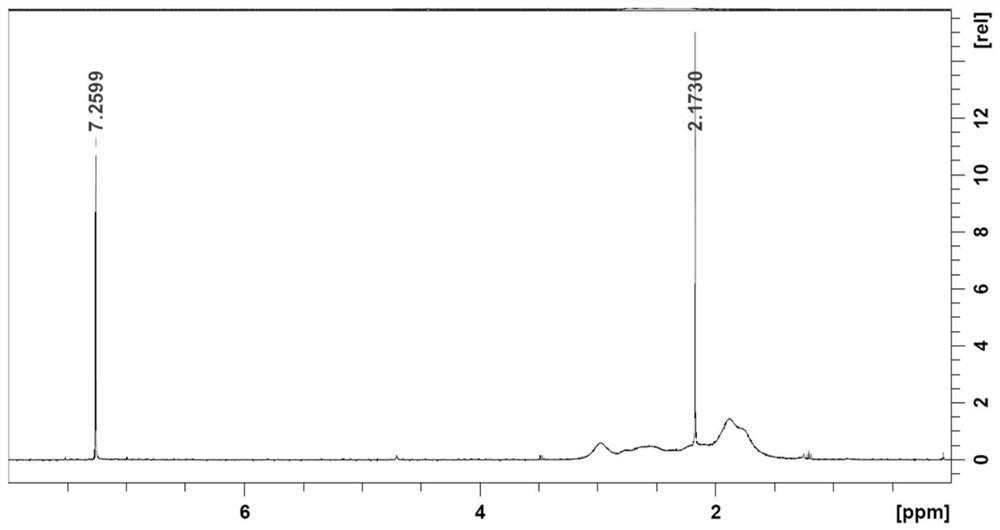

[0043] figure 1 It is the hydrogen spectrum of substance I: 1H NMR (400MHz, CDCl3) δ: 7.32 (t, J=11.0Hz, 4H), 7.09 (m, 6H) (aromatic H). It is worth noting that the chemical shifts of C-H(2H) belonging to the raw material p-carborane are all at 2.75, and the hydrogen spectrum of the product has disappeared, which means that the two hydrogens of p-carb...

Embodiment 2

[0062] 1. Preparation of new membranes modified with m-carborane-containing covalent organic framework materials

[0063] 1) Weigh 15 mg of m-carborane diamine compound and 18 mg of 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde, and conduct a hydrothermal reaction at 115°C for 70 hours to obtain a new type of m-carborane-containing COFs Material.

[0064] 2) Weigh the new m-carborane-containing COFs material, Ketjen black and polyvinylidene fluoride (PVDF) obtained by the hydrothermal reaction according to the weight ratio of 4:5:1, grind for 20 minutes, and place it in a closed beaker Add an appropriate amount of N-methylpyrrolidone (NMP) solvent dropwise, followed by strong magnetic stirring for 10 h to form a uniform slurry, which is evenly coated on a polypropylene diaphragm (Celgard 2400) with a scraper, modified The thickness of the layer was 23 μm, and it was dried naturally for 8 minutes, and then dried overnight at 70° C. in a vacuum oven. Finally, punch the dried d...

Embodiment 3

[0071] 1. Preparation of a novel separator containing p-carborane covalent organic framework materials

[0072] 1) Weigh 10 mg of p-carborane diamine compound, 15 mg of 5,10,15,20-tetrakis(4-benzaldehyde) porphyrin, and conduct a hydrothermal reaction at 125°C for 75 hours to obtain a new p-carborane-containing COFs material b.

[0073] 2) The new p-carborane-containing COFs material B, Ketjen black and 5% LA 133 obtained by hydrothermal reaction were weighed according to the weight ratio of 4:5::1, ground for 20 minutes, and placed in a closed beaker. Add an appropriate amount of mixed solvent of water and propanol dropwise, followed by strong magnetic stirring for 8 hours to form a uniform slurry, and use a scraper to evenly coat the slurry on a polypropylene diaphragm (Celgard2400), the thickness of the modified layer is 21 μm, and let it dry naturally for 6 minutes , and then dried overnight at 60°C in a vacuum oven. Finally, punch the dried diaphragm into a disc with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com