Preparation method of tea saponin ester succinate surfactant and product thereof

A surfactant and succinate technology, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problem that modified surfactants cannot meet the various needs of surfactants, complex processes, The problem of high preparation cost can achieve the effect of easy control of reaction conditions, simple preparation process and good surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

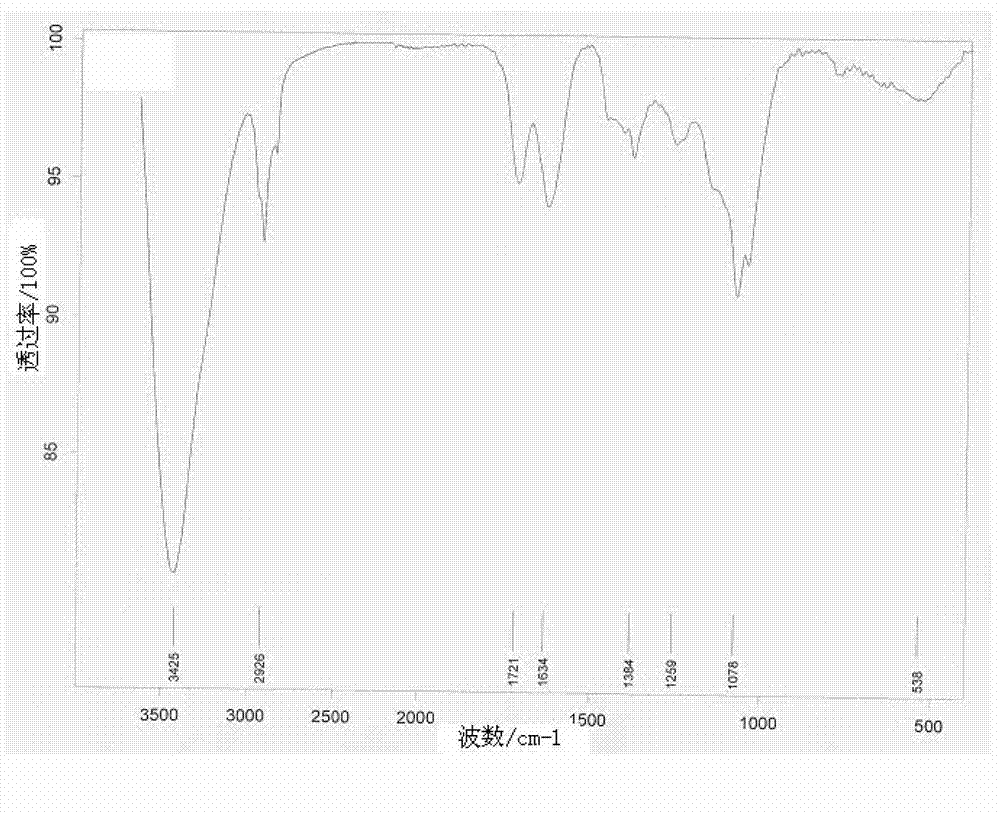

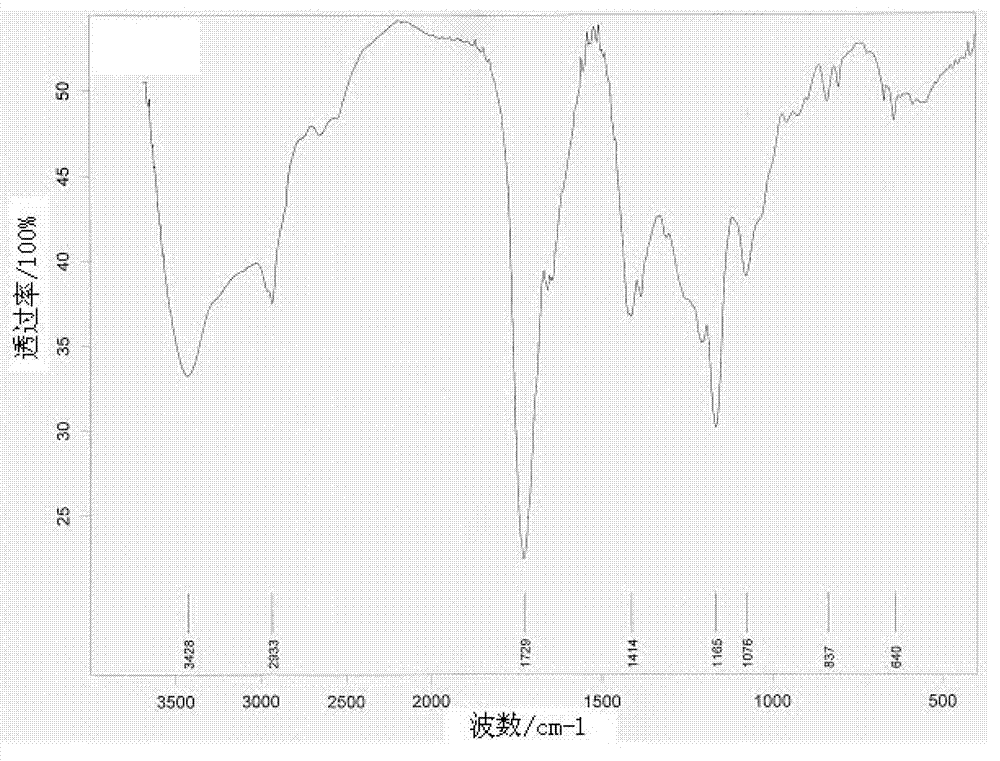

[0029]1 mmol of tea saponin, 5 mmol of succinic anhydride, and 5 mmol of anhydrous potassium carbonate were added to 20 ml of N,N-dimethylformamide, and the mixture was stirred and reacted at 25 degrees Celsius for 12 hours. After the reaction, add 10ml of water to the reaction solution for dilution, add AB-8 type macroporous adsorption resin to absorb tea saponin succinate, the adsorption time is 5 hours, TLC detection until the adsorption is complete. Remove the adsorption solution by suction filtration, add 2 times the volume of 80% ethanol to analyze the esterification product of tea saponin in the AB-8 type macroporous adsorption resin adsorbed with tea saponin succinate, rotate the evaporation to concentrate the analysis solution, and then The solid tea saponin succinate surfactant was obtained by vacuum freeze-drying. figure 1 It is the infrared spectrogram of tea saponin, figure 2 It is the infrared spectrogram of the tea saponin succinate surfactant prepared in embo...

Embodiment 2

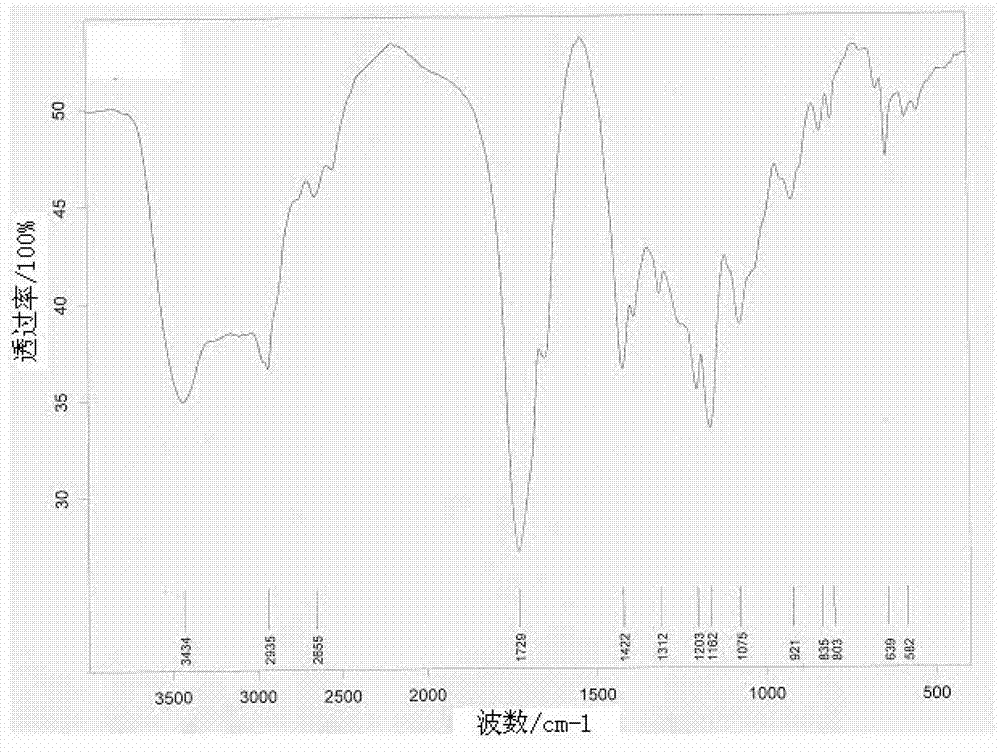

[0031] Add 1 mmol of tea saponin, 10 mmol of succinic anhydride, and 10 mmol of anhydrous potassium carbonate into 30 ml of N,N-dimethylformamide, and stir and react at 25 degrees Celsius for 12 hours. After the reaction, add 15ml of water to the reaction solution for dilution, add AB-8 type macroporous adsorption resin to absorb tea saponin succinate, the adsorption time is 5 hours, TLC detection until the adsorption is complete. Remove the adsorption solution by suction filtration, add three times the volume of 90% ethanol to analyze the esterification product of tea saponin in the AB-8 type macroporous adsorption resin adsorbed with tea saponin succinate, rotate the evaporation to concentrate the analysis solution, and then The solid tea saponin succinate surfactant was obtained by vacuum freeze-drying. image 3 The infrared spectrum of the tea saponin succinate surfactant prepared in embodiment 2.

Embodiment 3

[0033] 1 mmol of tea saponin, 20 mmol of succinic anhydride, and 20 mmol of anhydrous potassium carbonate were added to 35 ml of N,N-dimethylformamide, and stirred and reacted at 30 degrees Celsius for 16 hours. After the reaction, add 15ml of water to the reaction solution for dilution, add AB-8 type macroporous adsorption resin to absorb tea saponin succinate, the adsorption time is 6 hours, TLC detection until the adsorption is complete. Remove the adsorption solution by suction filtration, add four times the volume of 85% ethanol to analyze the esterification product of tea saponin in the AB-8 type macroporous adsorption resin adsorbed with tea saponin succinate, rotate the evaporation to concentrate the analysis solution, and then The solid tea saponin succinate surfactant was obtained by vacuum freeze-drying. Product infrared spectrogram is similar to embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com