Photosensitive mixed surfactant as well as preparation method and application thereof

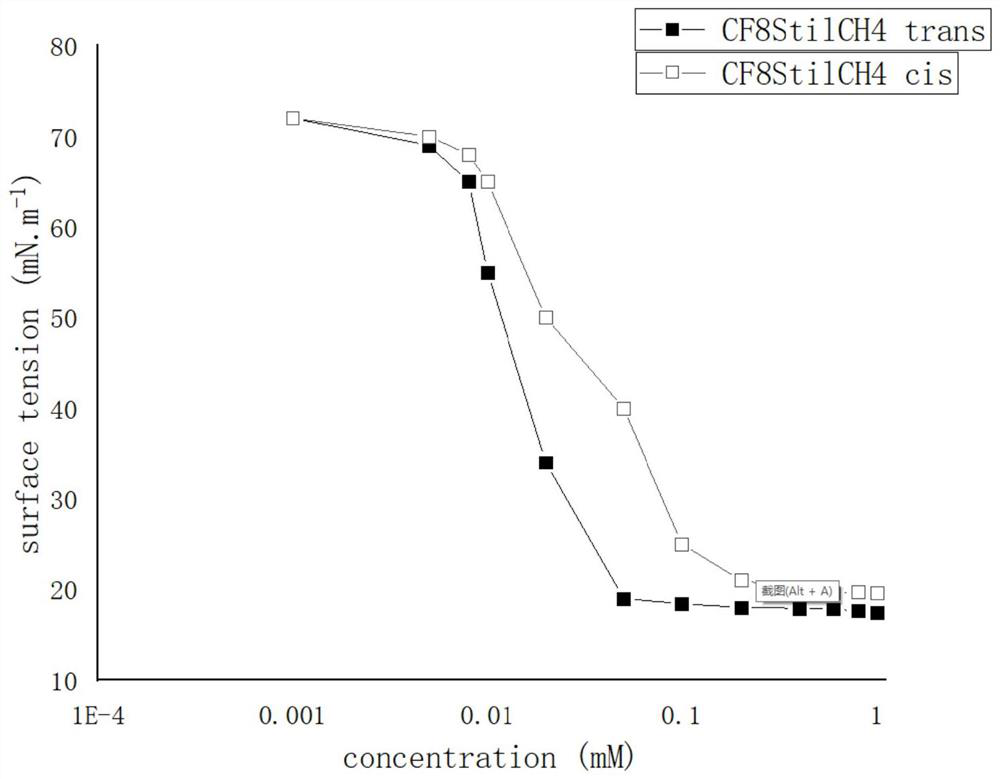

A surfactant and hybrid technology, which is applied in the field of photosensitive mixed surfactant and its preparation, can solve the problems of perfluorocarbon groups that have not been reported, and achieve the effect of significant surface activity and large surface tension difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

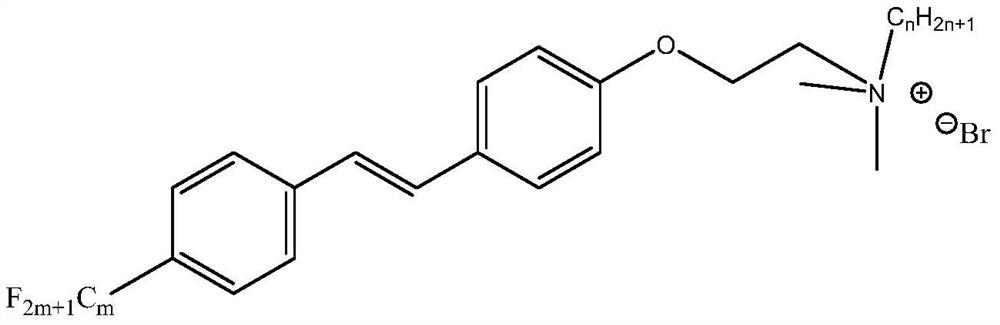

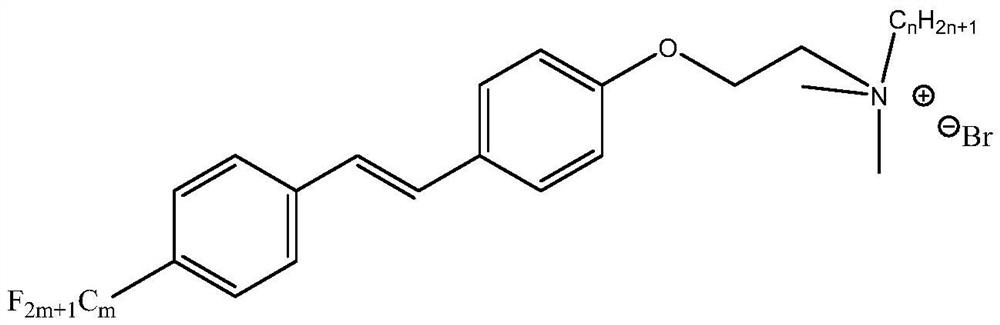

Method used

Image

Examples

preparation example Construction

[0048] The present invention further discloses the preparation method of the above-mentioned stilbene-based mixed surfactant, which specifically includes the following steps:

[0049](1) In terms of moles, put 50-100 parts of 1,4-diiodobenzene, 50-100 parts of perfluoroalkyl iodide, 150-300 parts of copper powder, and 900-1800 parts of dehydrated dimethyl Under dry N2 atmosphere, reflux at 120°C for 24h. After the reaction, the Cu powder was filtered off, and the precipitated solid was washed with ether and water successively.

[0050] (2) In terms of moles, put 50-100 parts of 4-(perfluoroalkyl) iodobenzene, 75-150 parts of 4-(vinyl)phenyl acetate, 500- 1000 parts of N-methyl-2-pyrrolidone as a solvent, 60-120 parts of potassium carbonate as an acid-binding agent, 25-50 parts of palladium acetate and 25-50 parts of 4-dimethylaminobutyric acid hydrochloride as a catalyst, 130 ℃ reaction 20h. The crude product was purified with chloroform, and the resulting chloroform soluti...

Embodiment 1

[0054] A 250ml three-necked flask is equipped with a thermometer, a reflux condenser, and a stirring magnet, and 29mmol of 1,4-diiodobenzene, 29mmol of perfluorooctyl iodide, 90mmol of copper powder, and 50ml of dehydrated dimethyl sulfoxide are placed in a dry N2 atmosphere , 120 ° C reflux reaction for 24h. After the reaction, the Cu powder was filtered off, and the precipitated solid was washed with ether and water successively.

[0055] A 250ml three-necked flask is equipped with a thermometer, a reflux condenser, and a stirring magnet, and 25mmol of 4-(perfluoroalkyl) iodobenzene obtained in the step reaction of (1), 37.5mmol of 4-(vinyl)phenyl acetate, and 50ml of N-methyl - 2-pyrrolidone as solvent, 30mmol potassium carbonate as acid-binding agent, 12mmol palladium acetate and 12mmol 4-dimethylaminobutyric acid hydrochloride as catalyst, react at 130°C for 20h. The crude product was purified with chloroform, and the resulting chloroform solution was washed successively...

Embodiment 2

[0059] A 250ml three-necked flask is equipped with a thermometer, a reflux condenser, and a stirring magnet, and 29mmol of 1,4-diiodobenzene, 29mmol of perfluorooctyl iodide, 150mmol of copper powder, and 100ml of dehydrated dimethyl sulfoxide are placed in a dry N2 atmosphere , 120 ° C reflux reaction for 24h. After the reaction, the Cu powder was filtered off, and the precipitated solid was washed with ether and water successively.

[0060] A 250ml three-necked flask is equipped with a thermometer, a reflux condenser, a stirring magnet, and 25mmol of 4-(perfluoroalkyl) iodobenzene obtained in the step reaction of (1), 50mmol of 4-(vinyl)phenyl acetate, 50ml of N-methyl- 2-Pyrrolidone was used as a solvent, 35mmol potassium carbonate was used as an acid-binding agent, 12mmol palladium acetate and 12mmol 4-dimethylaminobutyric acid hydrochloride were used as catalysts, and the reaction was carried out at 130°C for 20h. The crude product was purified with chloroform, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com