Acidizing corrosion inhibitor applicable to high temperature of 140 to 160 DEG C, and preparation and application thereof

A technology of acidizing corrosion inhibitor and high temperature, applied in chemical instruments and methods, production fluids, wellbore/well components, etc., can solve the problems of easy coking, corrosion inhibitor damage, decline in corrosion inhibition effect, etc., and achieve a simple production process. , good surface activity, low freezing point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

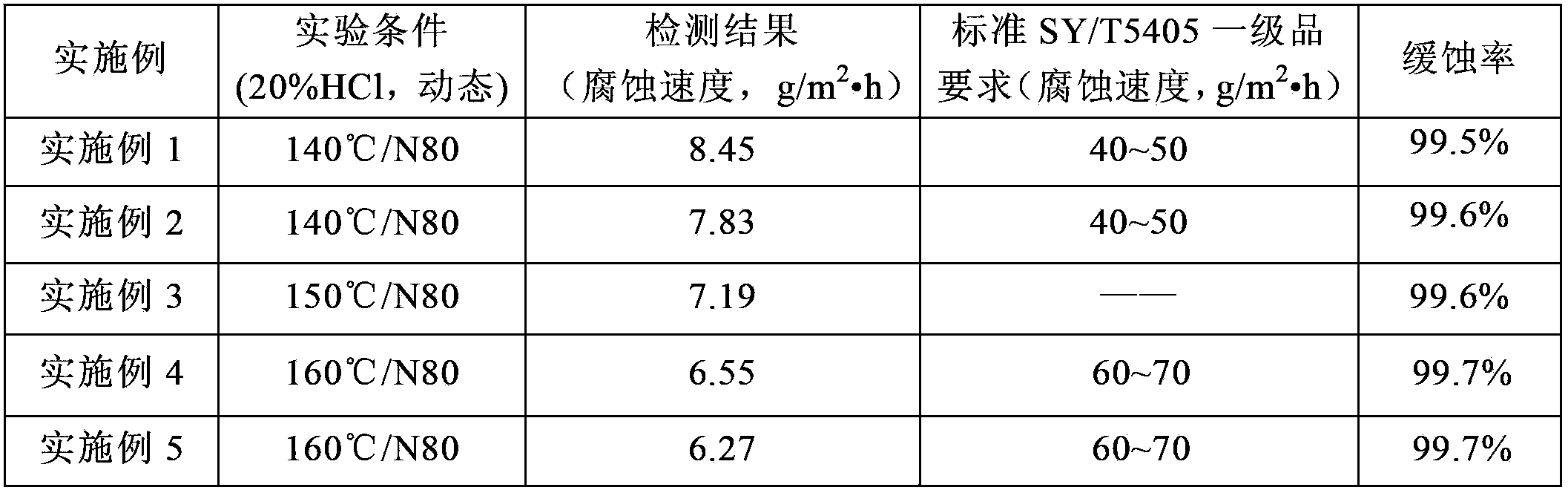

Examples

Embodiment 1

[0061] Example 1: A corrosion inhibitor suitable for high temperature acidification at 140°C, the weight percentage of component A is:

[0062] Polycyclic aromatic hydrocarbon chloromethyl pyridinium quaternary ammonium salt: 30%;

[0063] 3-methyl-1-pentyn-3-ol: 0.6%;

[0064] Glyoxal: 0.1%;

[0065] Dimethylformamide: 2%;

[0066] Hydroxyethylcellulose: 0.5%;

[0067] Emulsifier OPE-20: 15%;

[0068] Methanol; 51.8%.

[0069] B component weight percent is:

[0070] Potassium antimony tartrate: 15%;

[0072] Vitamin C: 10%;

[0073] 1+1 hydrochloric acid: 60%.

[0074] The batch composition during use is the A liquid of 3 weight parts and the B liquid of 1 weight part.

[0075] The preparation method is:

[0076] The preparation method of A component is:

[0077]Add 50% methanol in proportion to the enamel reaction kettle, slowly raise the temperature to 55-60°C, add hydroxyethyl cellulose under constant stirring, stir until all hydrox...

Embodiment 2

[0080] Example 2: A corrosion inhibitor suitable for high temperature acidification at 140°C, the weight percentage of component A is:

[0081] Polycyclic aromatic hydrocarbon chloromethyl pyridinium quaternary ammonium salt: 31%;

[0082] 3-methyl-1-pentyn-3-ol: 0.5%;

[0083] Glyoxal: 0.15%;

[0084] Dimethylformamide: 3%;

[0085] Hydroxyethylcellulose: 1%;

[0086] Emulsifier OPE-20: 15.5%;

[0087] Methanol; 48.85%.

[0088] B component weight percent is:

[0089] Potassium antimony tartrate: 16%;

[0091] Vitamin C: 11%;

[0092] 1+1 hydrochloric acid: 59%.

[0093] The batch composition during use is the A liquid of 3 weight parts and the B liquid of 1 weight part.

[0094] Example 2 The preparation method of a corrosion inhibitor suitable for 140°C high-temperature acidification is the same as that of Example 1.

Embodiment 3

[0095] Example 3: A corrosion inhibitor suitable for high temperature acidification at 150°C, the weight percentage of component A is:

[0096] Polycyclic aromatic hydrocarbon chloromethyl pyridinium quaternary ammonium salt: 33%;

[0097] 3-methyl-1-pentyn-3-ol: 0.4%;

[0098] Glyoxal: 0.2%;

[0099] Dimethylformamide: 4%;

[0100] Hydroxyethylcellulose: 1.5%;

[0101] Emulsifier OPE-20: 16%;

[0102] Methanol; 44.9%.

[0103] B component weight percent is:

[0104] Potassium antimony tartrate: 17%;

[0105] Bismuth oxide: 13%;

[0106] Vitamin C: 13%;

[0107] 1+1 hydrochloric acid: 57%.

[0108] The batch composition during use is the A liquid of 2.5 weight parts and the B liquid of 1 weight part.

[0109] Example 3 The preparation method of a corrosion inhibitor suitable for 150°C high temperature acidification is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com