rubber compound

A rubber compound, rubber technology, used in transportation and packaging, thin material handling, etc., can solve problems such as high hysteresis loss and poor dynamic behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

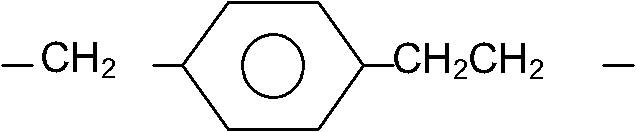

Image

Examples

Embodiment 1

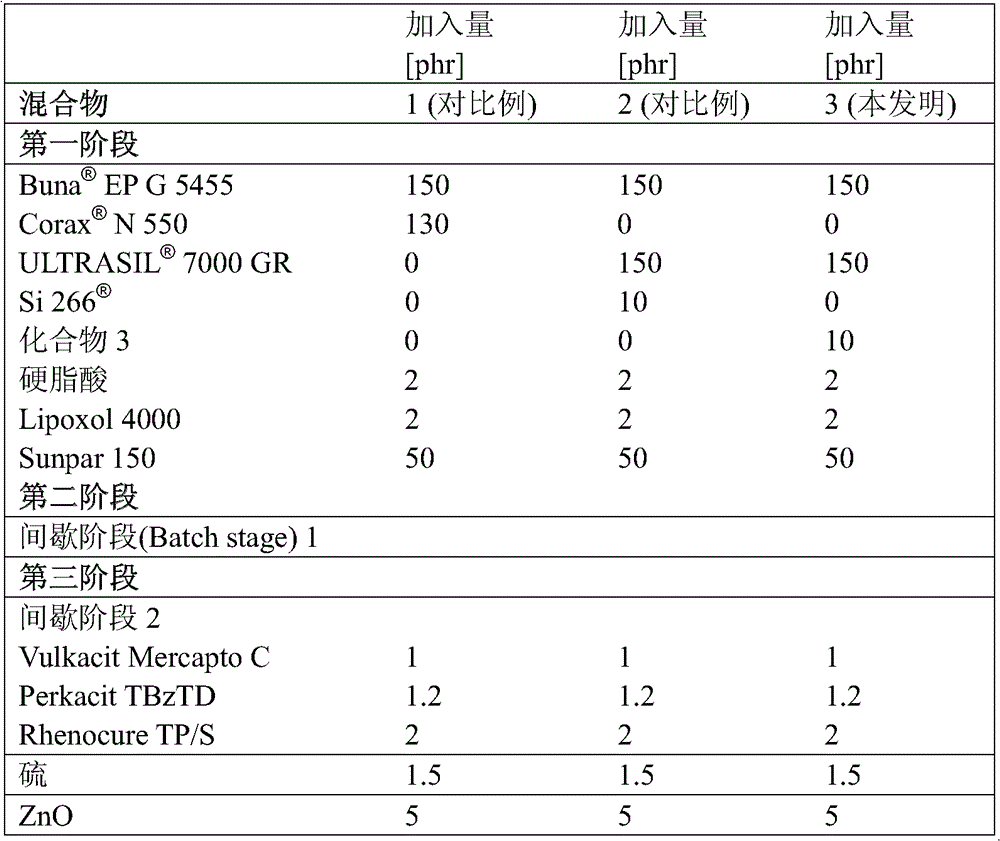

[0131] Example 1: Rubber Mixture

[0132] The main mixing specification (Main mixing specification) for the rubber mixture is listed in Table 1 below. The unit of phr used here is part by weight, based on 100 parts of crude rubber used.

[0133] A general method of producing rubber compounds and their vulcanizates is described in the "Rubber Technology Handbook", W. Hofmann, Hanser Verlag 1994.

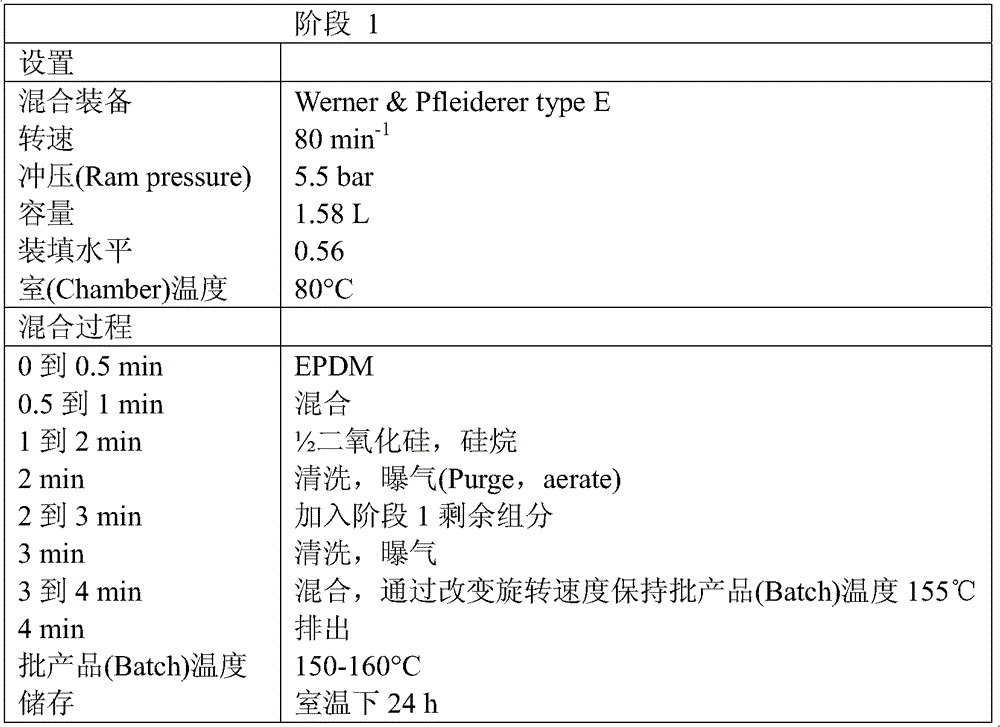

[0134] Table 1: Main mixing methods

[0135]

[0136] polymer EPG5455 is an ethylene propylene diene rubber with medium degree of unsaturation (ENB content=4,3) containing 50 phr paraffin oil from Lanxess. Its Mooney viscosity (Mooney viscosity) (UML (1+4) 125° C.) is 46.

[0137] 7000GR is highly disperse silica from EvonikDegussa GmbH with a BET surface area of 170m 2 / g.

[0138] Lipoxol 4000 from Sasol is polyethylene glycol 4000, Sunpar 150 from Holly Corporation is paraffin oil, VulkacitMercaptoC from Lanxess is 2-mercaptobenzothiazole (MBT), PerkacitTBzTD (tetrabe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com