Method for producing biodiesel by catalyzing microalgae oil by ultrasonic-assisted ionic liquid

An ionic liquid, catalyzing microalgae technology, applied in the direction of fat oil/fat production, biofuel, fat production, etc., can solve the problems of low extraction efficiency, environmental pollution, high cost, reduce reaction time, reduce production cost, and save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

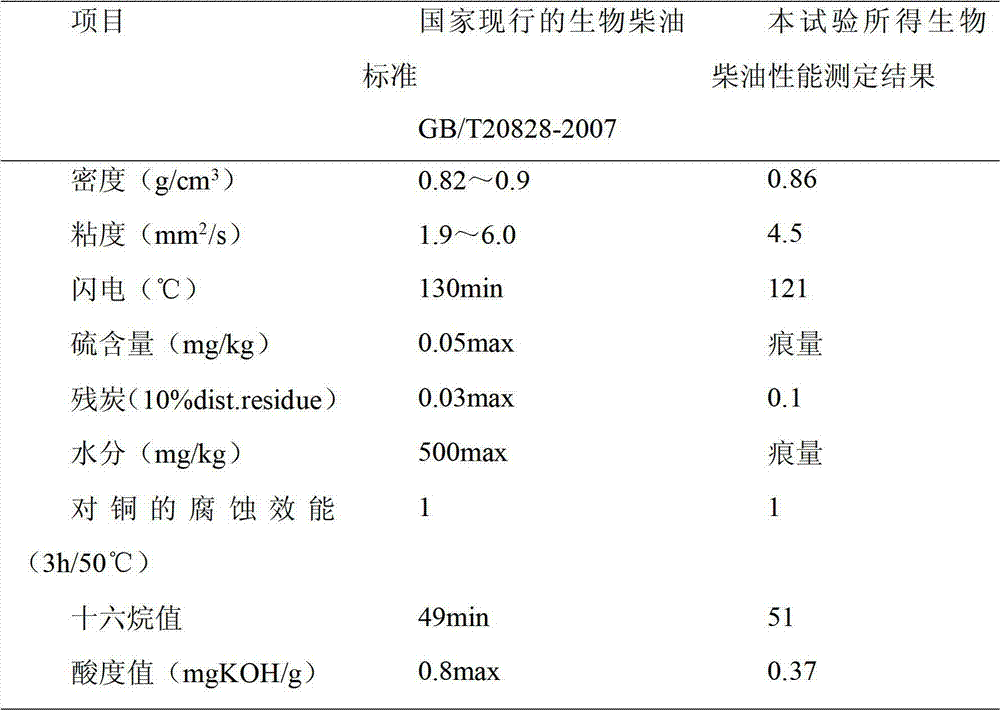

Examples

specific Embodiment approach 1

[0015] Specific embodiment one: the method for a kind of ultrasonic-assisted ionic liquid catalyzed microalgae oil production biodiesel of the present embodiment is to carry out according to the following steps: one, the molar ratio of N-methylimidazole and chlorinated n-butane is 1 : Mix the ratio of 1~2 evenly, under the condition of nitrogen protection, stir and react at 70℃~80℃ for 40~50h, after cooling and crystallizing, the solid [BMIM]Cl can be obtained; 2. The [BMIM]Cl obtained in step 1 ]Cl and NaBF 4 Mix the mixture with a molar ratio of 1:1 to obtain a mixture; mix the mixture with acetone at a mass volume ratio of 1g:10~30mL, stir and react at room temperature for 18~24h to obtain a solid-liquid mixture, and mix the solid-liquid mixture After filtration, the filtrate was collected for vacuum distillation, and the collected fraction was dried for 10-15 hours at a vacuum of 0.09-0.092MPa and a temperature of 60-80°C to obtain the ionic liquid [BMIM]BF 4 3. Mix the m...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment differs from Embodiment 1 in that the stirring speed in Step 1 and Step 2 is 300-800 r / min. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the vacuum distillation described in Step 2 and Step 4 refers to distillation at a pressure of 0.09~0.092Mpa for 0.5~2.5h. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com