Multi-head screw single-screw pump for conveying double-foam insulation slurry

A technology of thermal insulation slurry and multi-head screw, which is applied to rotary piston pumps, rotary piston/swing piston pump components, pumps, etc., can solve problems such as high cost of spare parts, difficult disassembly and maintenance, and long downtime. Achieve the effects of stable operation, convenient disassembly and maintenance, and stable viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

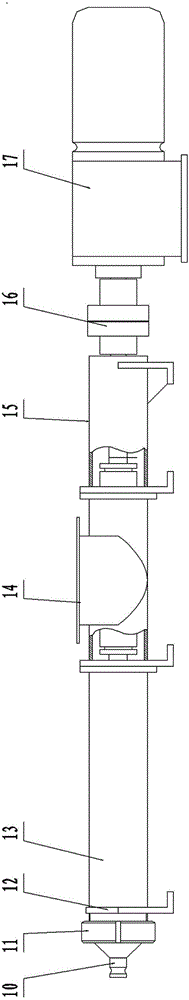

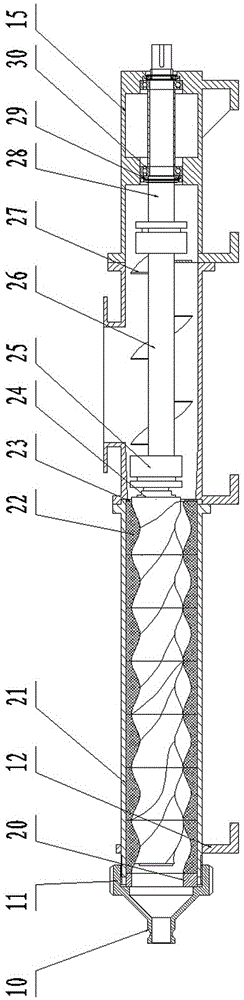

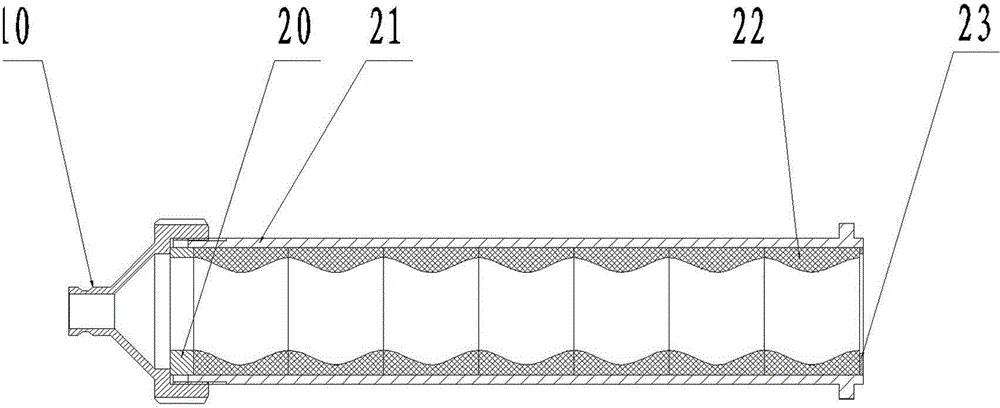

[0053] Such as figure 1 , figure 2 , Figure 4 (b) figure, Figure 5 , Figure 8 , Figure 12 (b) figure, Figure 13 (a) As shown in the figure; the cross-sectional shape of the three-head spiral elastic sleeve 22 of the multi-head screw single-screw pump of the multi-head screw single-screw pump for conveying double-foam insulation slurry is arc-triangular in shape, and its length is 1 / 2 pitch, and the double-head screw rotor 24 The cross-sectional shape of the head screw rod is oval, and the keys are evenly distributed with four.

Embodiment 2

[0055] Such as figure 1 , figure 2 , Figure 4 (b) figure, Figure 5 , Figure 8 , Figure 12 (b) figure, Figure 13 (a) As shown in the figure; the cross-sectional shape of the three-head spiral elastic sleeve 22 of the multi-head screw single-screw pump of the multi-head screw single-screw pump for conveying double-foam insulation slurry is arc-triangular in cross-section, and its length is 1 / 4 pitch. The cross-sectional shape of the head screw rod is oval, and the keys are evenly distributed with four.

Embodiment 3

[0057] Such as figure 1 , figure 2 , Figure 4 (b) figure, Figure 5 , Figure 8 , Figure 12 (a) Figure, Figure 13 (a) As shown in the figure; the cross-sectional shape of the three-head spiral elastic sleeve 22 of the multi-head screw single-screw pump of the multi-head screw single-screw pump for conveying double-foam insulation slurry is arc-triangular in cross-section, and its length is 1 / 4 pitch. The cross-sectional shape of the head screw rod is an arc rectangle, and four keys are evenly distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com