Method for determining chromium content and aluminum content in nickel-chromium-aluminum coated diatomite

A technology for coating diatomite and nickel-chromium-aluminum, which is applied in the field of elemental analysis of nickel-chromium-aluminum-coated diatomite, can solve the problems of difficulty in dissolving the sample, long dissolution time, long analysis period, etc., so as to improve the accuracy and the method is accurate and reliable. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

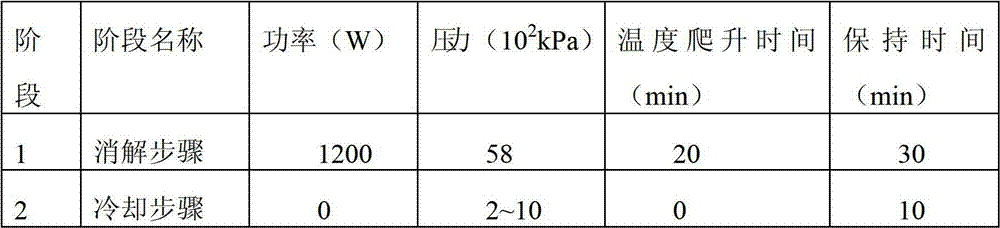

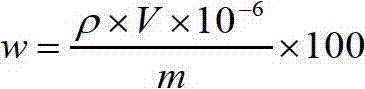

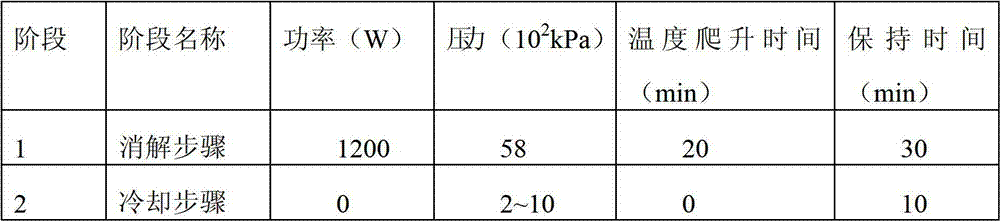

Examples

Embodiment 1

[0035] The content of chromium and aluminum in nickel-chromium-aluminum-coated diatomite is determined by using an inductively coupled plasma emission spectrometer (French JY170). The working conditions and analysis lines of the instrument are as follows: high-frequency frequency: 40.68MHz; incident power: 1.0Kw; reflected power : <15W; argon gas flow: cooling gas flow: 15L / min; sheath gas flow: 0.2L / min; incident slit: 20μm; exit slit: 80μm; 2s; element analysis line: chromium 267.716nm, aluminum 394.401nm;

[0036] (1) The reagents used in the determination process are as follows:

[0037] (1.1), hydrochloric acid, ρ1.19g / mL, superior grade or high purity or MOS grade;

[0038] (1.2), nitric acid, ρ1.42g / mL, superior grade or high purity or MOS grade;

[0039] (1.3), hydrofluoric acid, ρ about 1.15g / mL, excellent grade or high purity or MOS grade;

[0040] (1.4), chromium standard solution with a mass fraction not less than 99.99%: 1.00mg / mL, weigh 0.5000g of high-purity ...

Embodiment 2

[0056] The content of chromium and aluminum in nickel-chromium-aluminum-coated diatomite is determined by using an inductively coupled plasma emission spectrometer (IRIS intrepid II in the United States). The working conditions and analysis lines of the instrument are as follows: high-frequency frequency: 40.68MHz; incident power: 1.15Kw ; Reflected power: <15W; Argon gas flow: cooling gas flow: 15L / min; auxiliary gas flow: 1.0L / min; pump speed: flushing pump speed 120rpm (2.22ml / min); analysis pump speed 120rpm (2.22ml / min min); UV integration time: 3s; element analysis line: chromium 267.716nm, aluminum 394.401nm;

[0057] (1) The reagents used in the determination process are as follows:

[0058] (1.1), hydrochloric acid, ρ1.19g / mL, superior grade or high purity or MOS grade;

[0059] (1.2), nitric acid, ρ1.42g / mL, superior grade or high purity or MOS grade;

[0060] (1.3), hydrofluoric acid, ρ about 1.15g / mL, excellent grade or high purity or MOS grade;

[0061] (1.4), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com