Movable narrow crack blade

A blade and slit technology, applied in the field of adjustable lithography machine components, can solve the problems of thermal deformation of the movable blade, interference of the exposure process, and no better method, so as to improve control accuracy, reduce deformation, and improve maintainability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

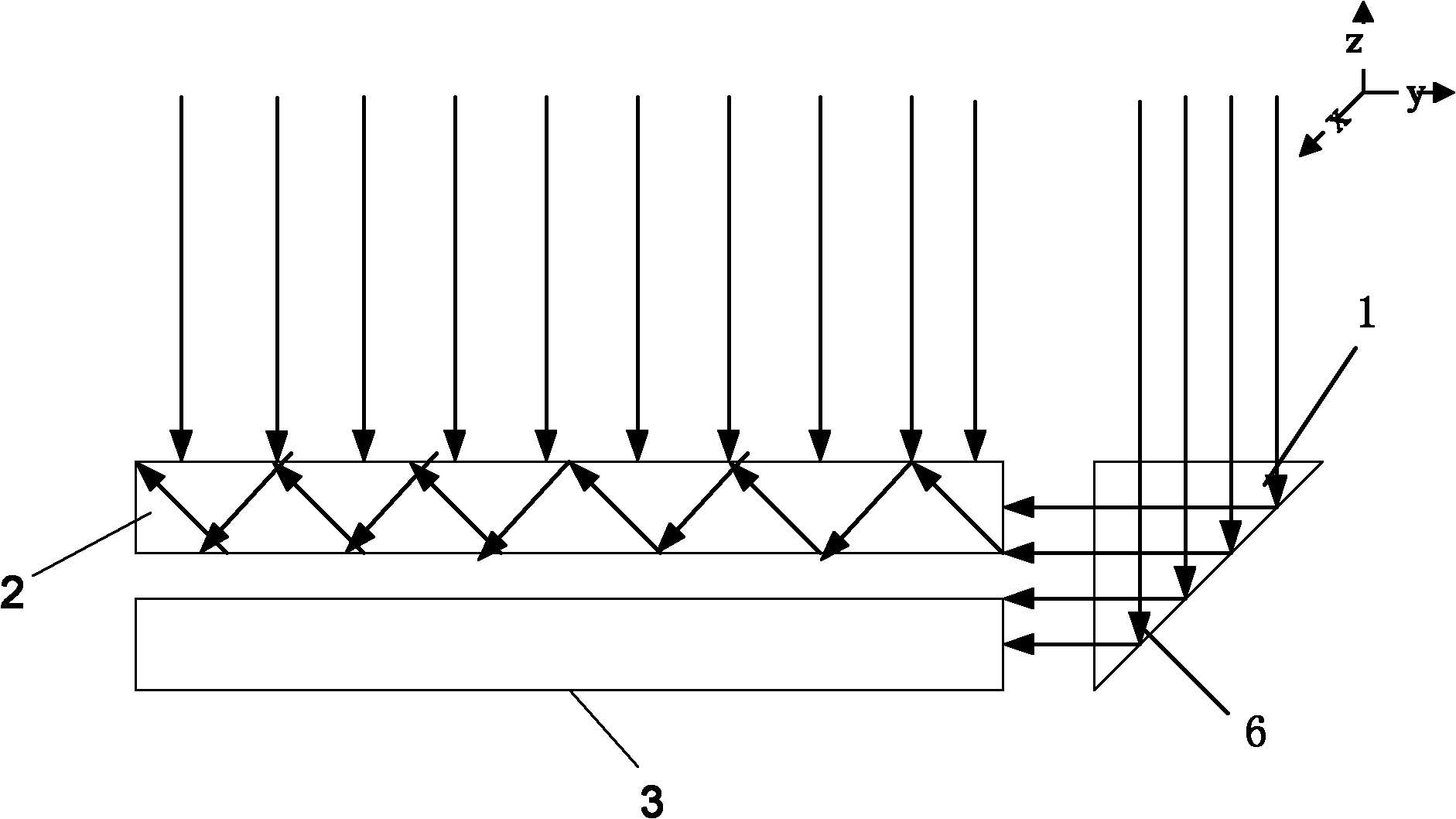

[0028] Please see figure 1 . figure 1 Shown is a schematic structural view of the movable slit blade in the embodiment of the present invention.

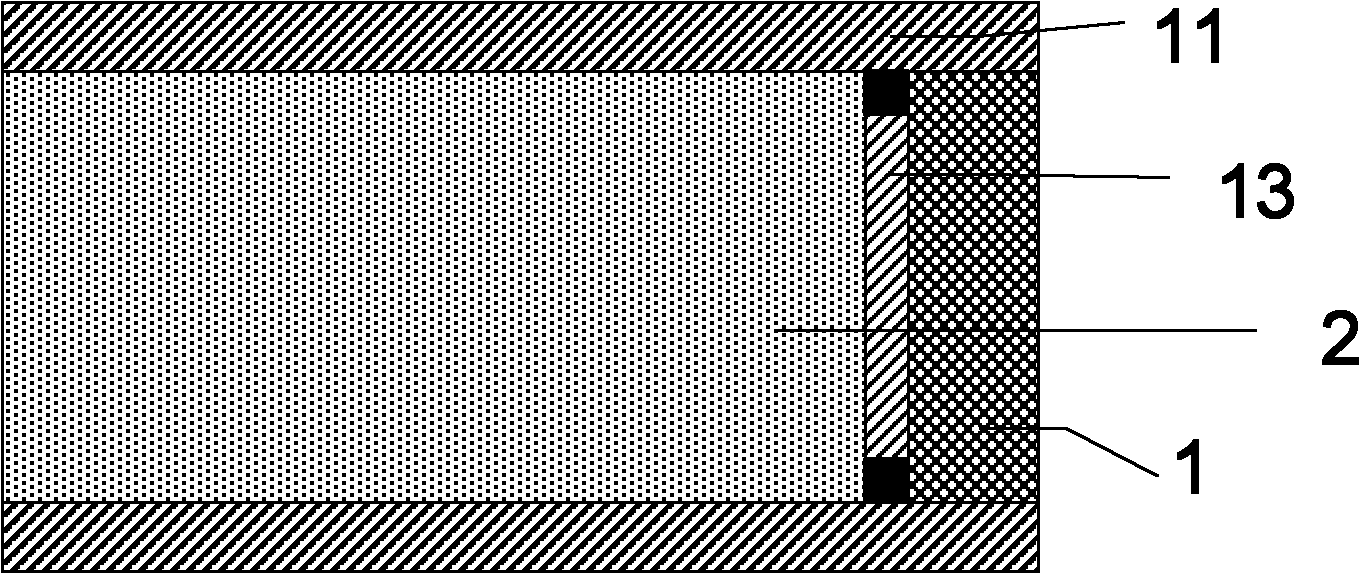

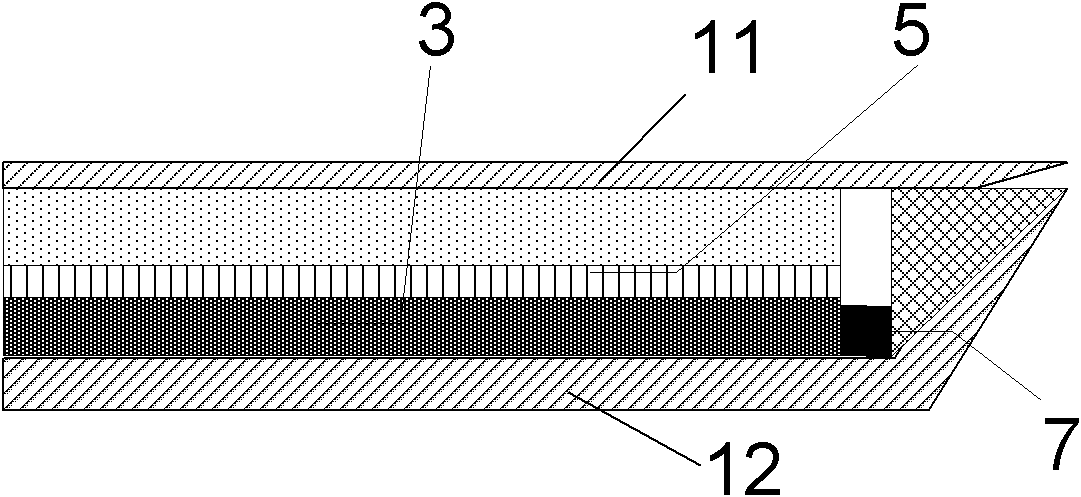

[0029] The structure of a blade 10 of the movable slit is as figure 1 As shown, a light-transmitting plate 2 and a light-absorbing sheet 3 are arranged along the incident light direction. In addition, the blade 10 also includes a reflective prism 1, which is located on the side of the light-transmitting plate 2 and the light-absorbing sheet 3, and there is a gap G between the light-transmitting plate 2 and the light-absorbing sheet 3. .

[0030] The transparent plate 2 is, for example, a quartz plate for transmitting incident light. In order to increase the light transmission capability of the light-transmitting plate 2 , an anti-reflection film may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com