Semiconductor device and manufacture method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of poor reverse breakdown characteristics of devices, affect device electrical parameters and reliability, and cannot form Schottky potential To improve the reverse breakdown characteristics, save the area of a single cell, and achieve miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

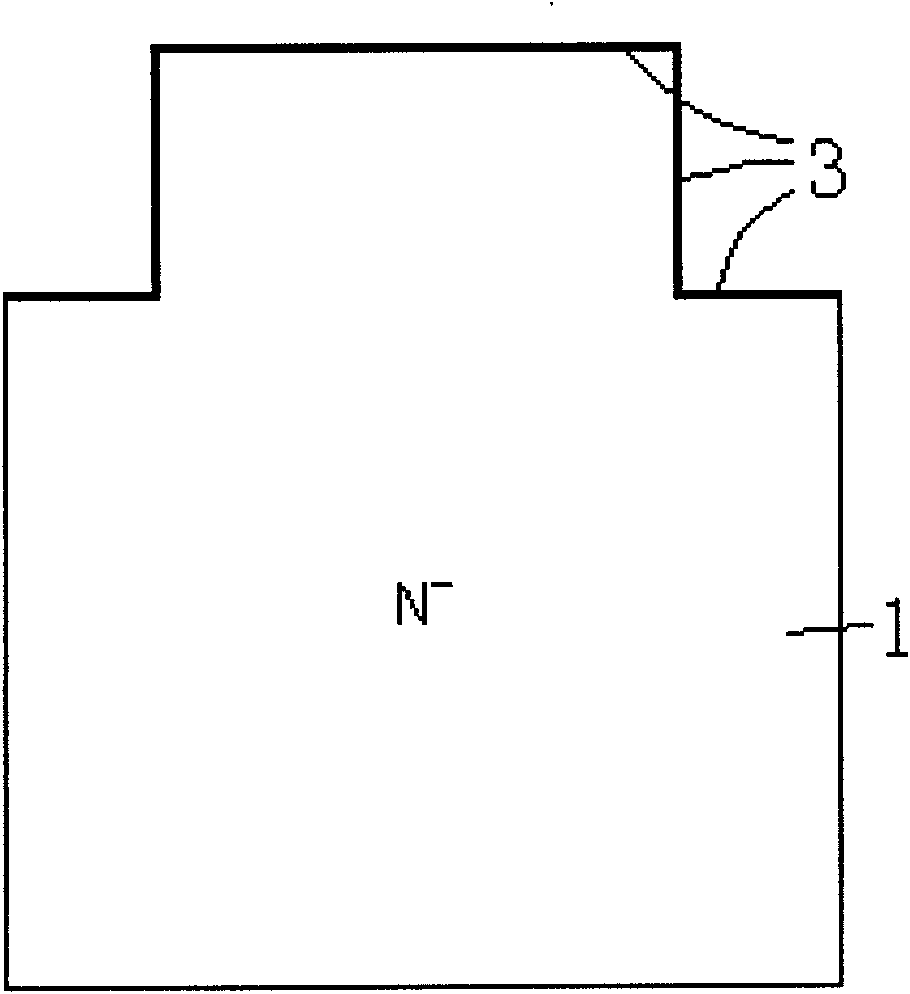

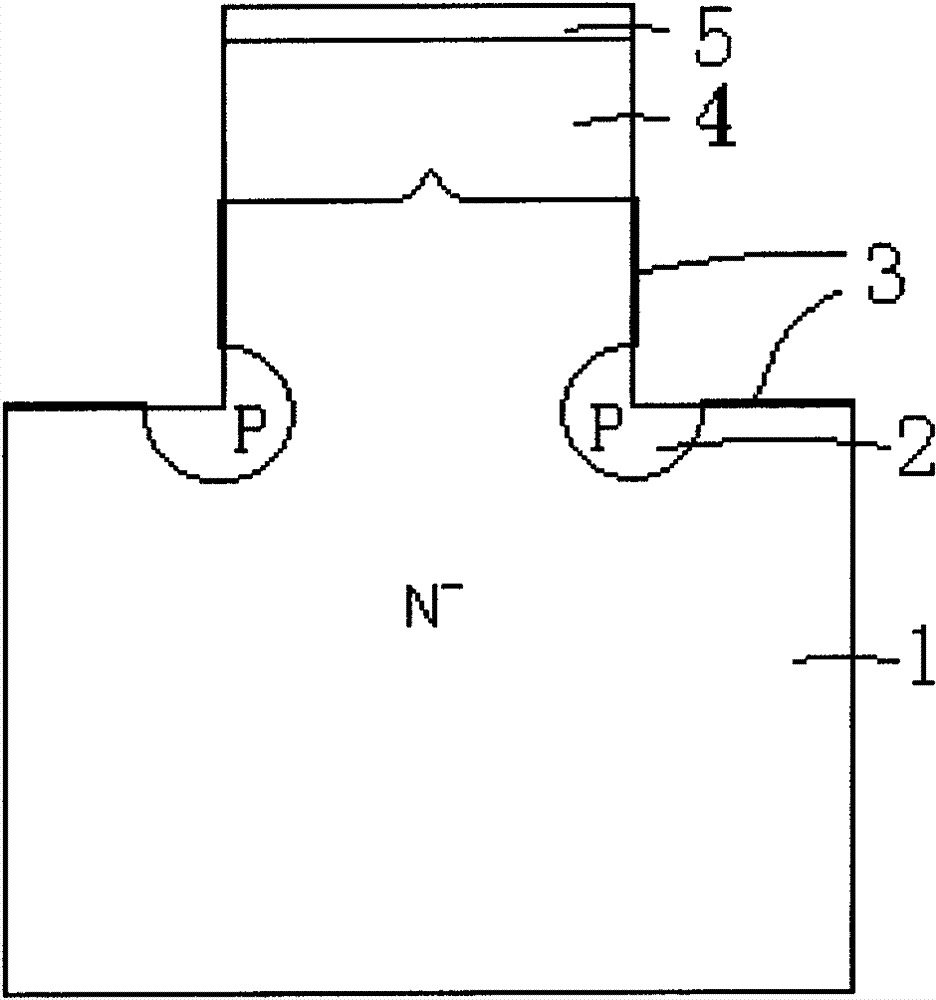

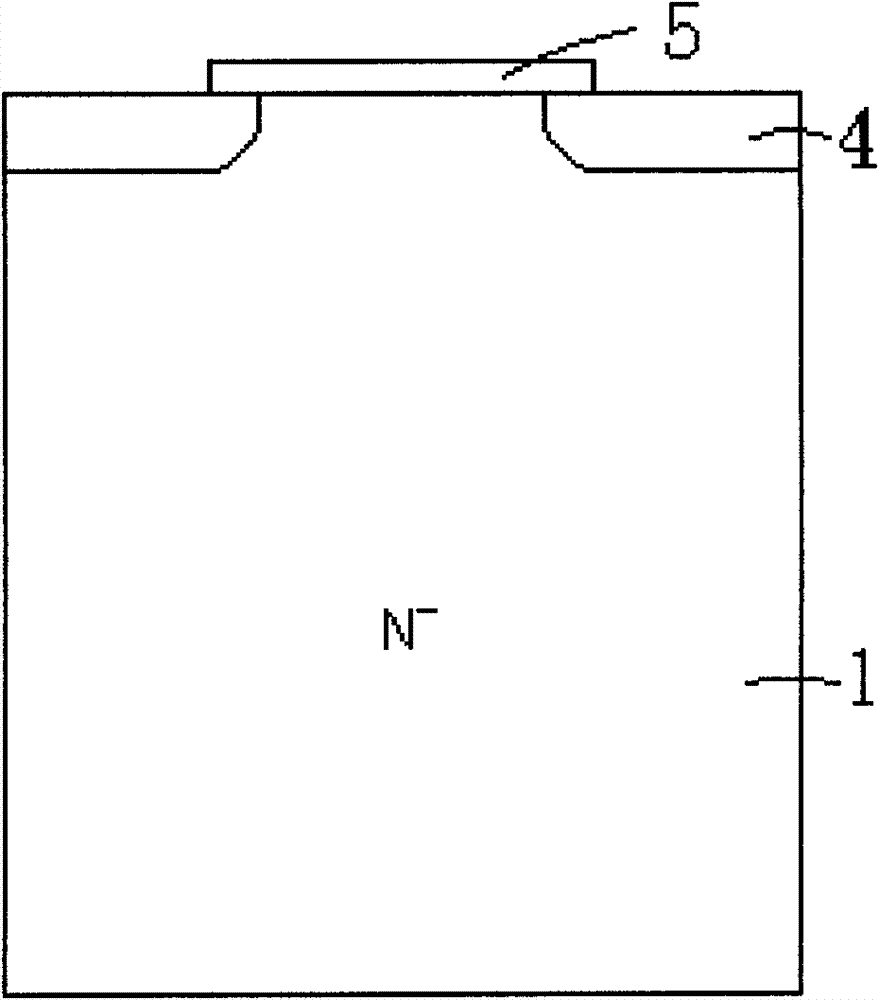

[0026] figure 2 It is a schematic cross-sectional view of a single cell of the semiconductor device of the present invention, which includes: N-type conductive semiconductor material 1, which is a lightly doped N-conductive type silicon semiconductor material, and a P-type conductive material area on the upper surface of the N-type conductive semiconductor material 4. At the same time, the depth of the trench formed by the etching process is greater than the depth of the P-type conductive material region 4; the P-type conductive material region 2 at the bottom of the trench is located in the semiconductor material body at the corner of the bottom edge of the trench; on the sidewall of the trench The surface of the N-type conductive semiconductor material and the bottom is the Schottky barrier junction 3; the oxide layer 5 is located on the surface of the semiconductor material between the trenches.

[0027] The manufacturing process includes the following steps: in the first step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com