Preparation method of NbTi superconducting wire joint

A production method and technology of superconducting joints, which are applied in the direction of connecting contact materials, connections, circuit/collector components, etc., can solve the problems of inconvenient operation, unstable performance, and low yield rate, etc. Simple, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

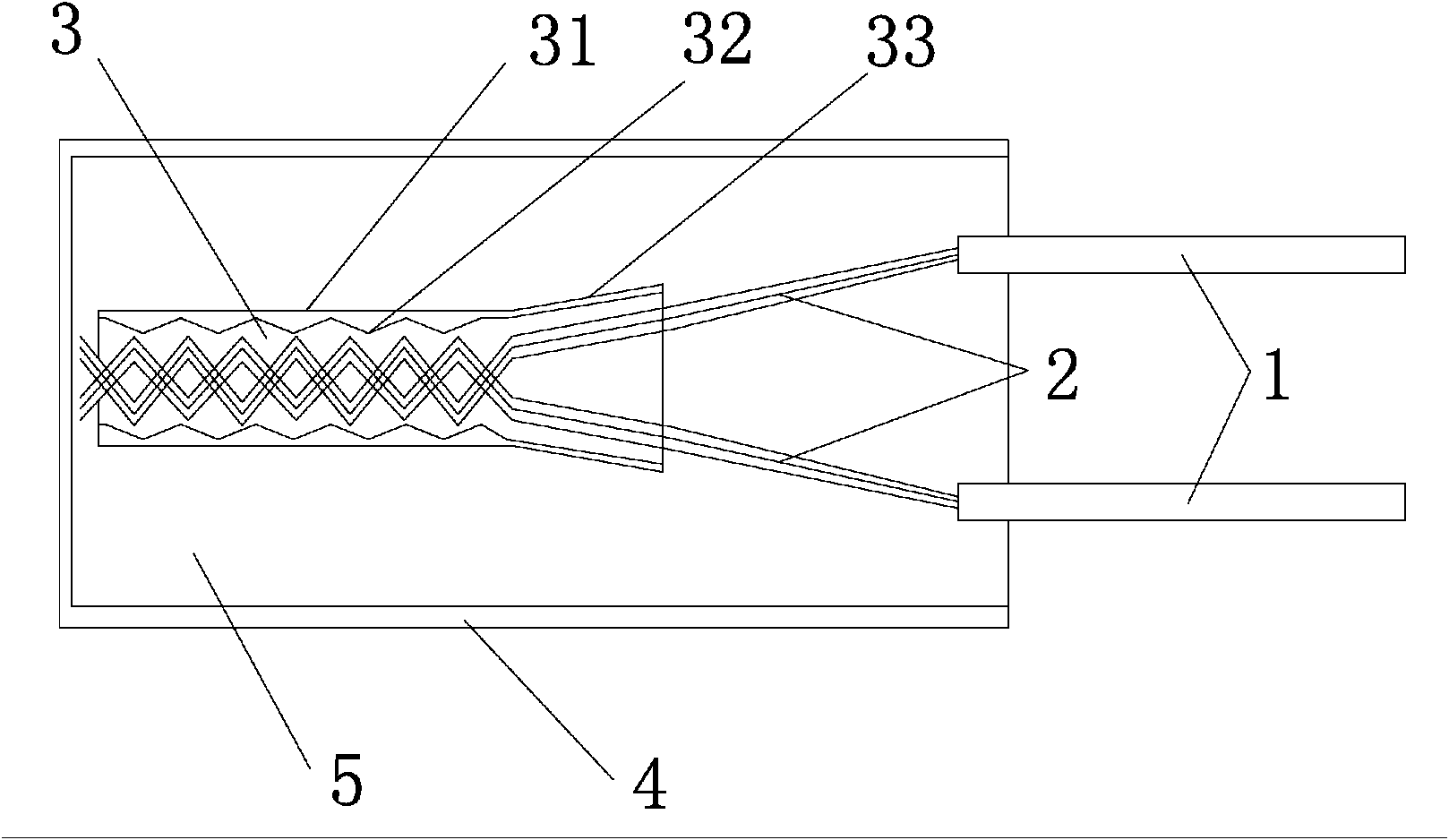

[0026] like figure 1 Shown is a schematic diagram of the structure of the superconducting joint provided by the present invention. The connector has the advantages of simple structure, easy manufacture, stable performance, low resistance, etc., including:

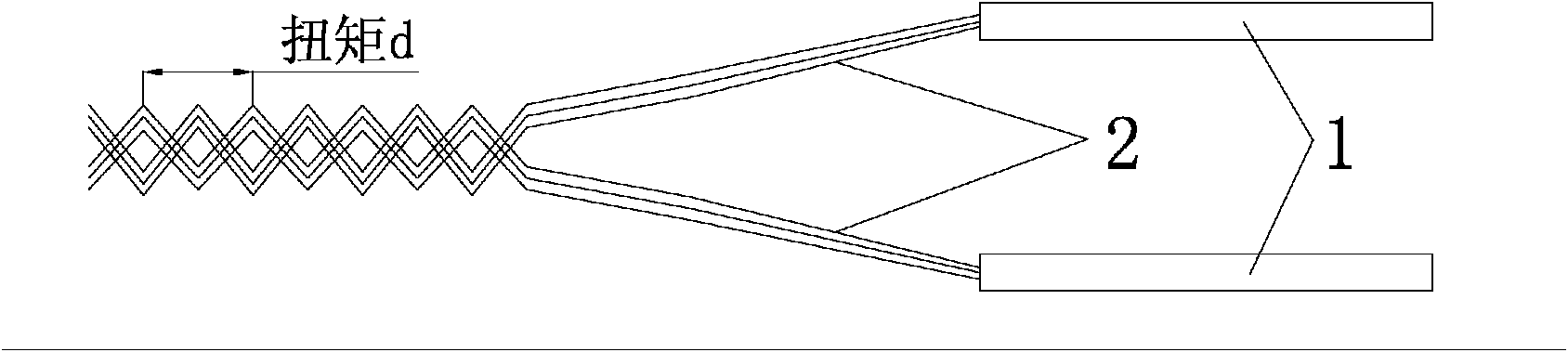

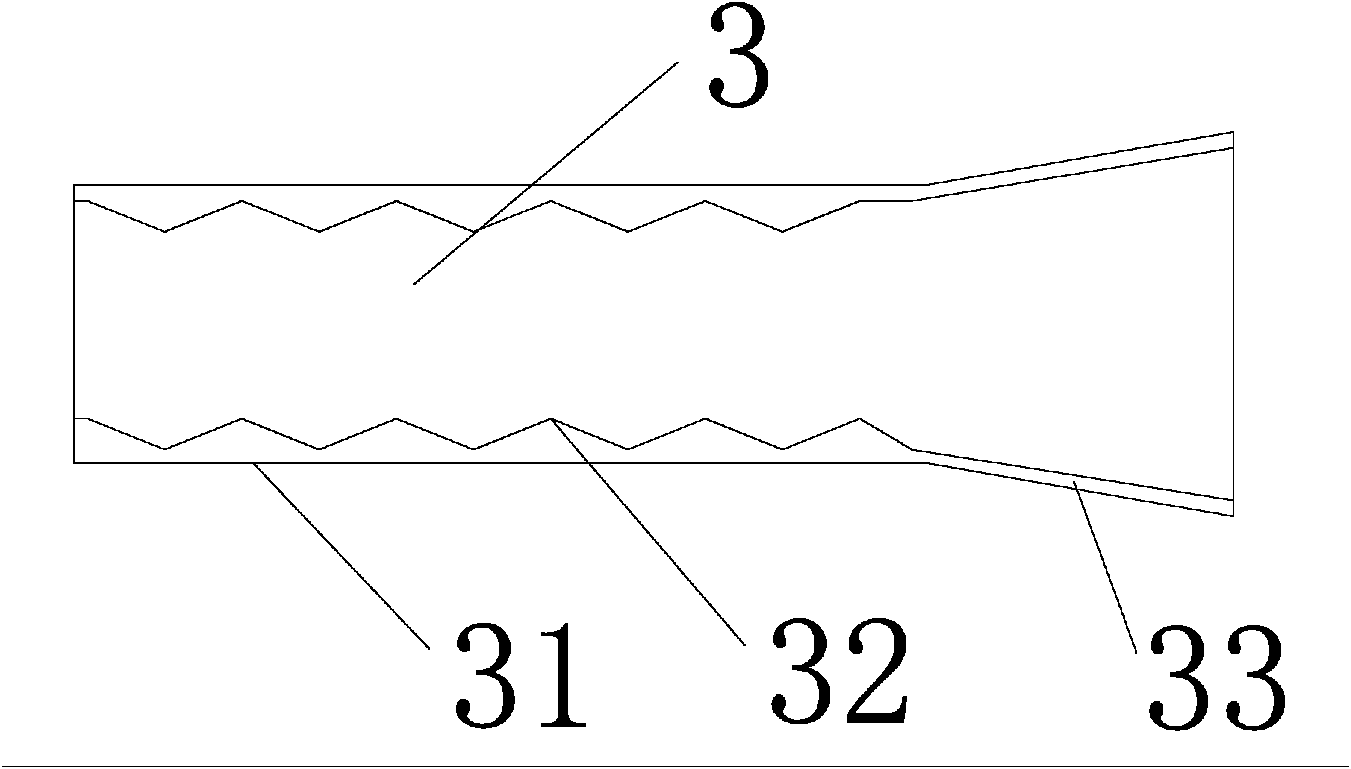

[0027] The NbTi composite superconducting wire (1) is etched with acid to remove stable substrates such as copper or aluminum at its end to form a NbTi superconducting wire (2). Twist and braid the superconducting wires (2) of several superconducting wires that need to make superconducting joints, clean the stains on the surface of the superconducting wires (2) with alcohol or acetone, clean and dry, and insert them into the NbTi cold-pressed tube (3) inside.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com