Method and arrangement for removing gas from a liquid

A technology for removing and gas, applied in the direction of liquid degassing, separation methods, chemical instruments and methods, etc., to achieve the effect of effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

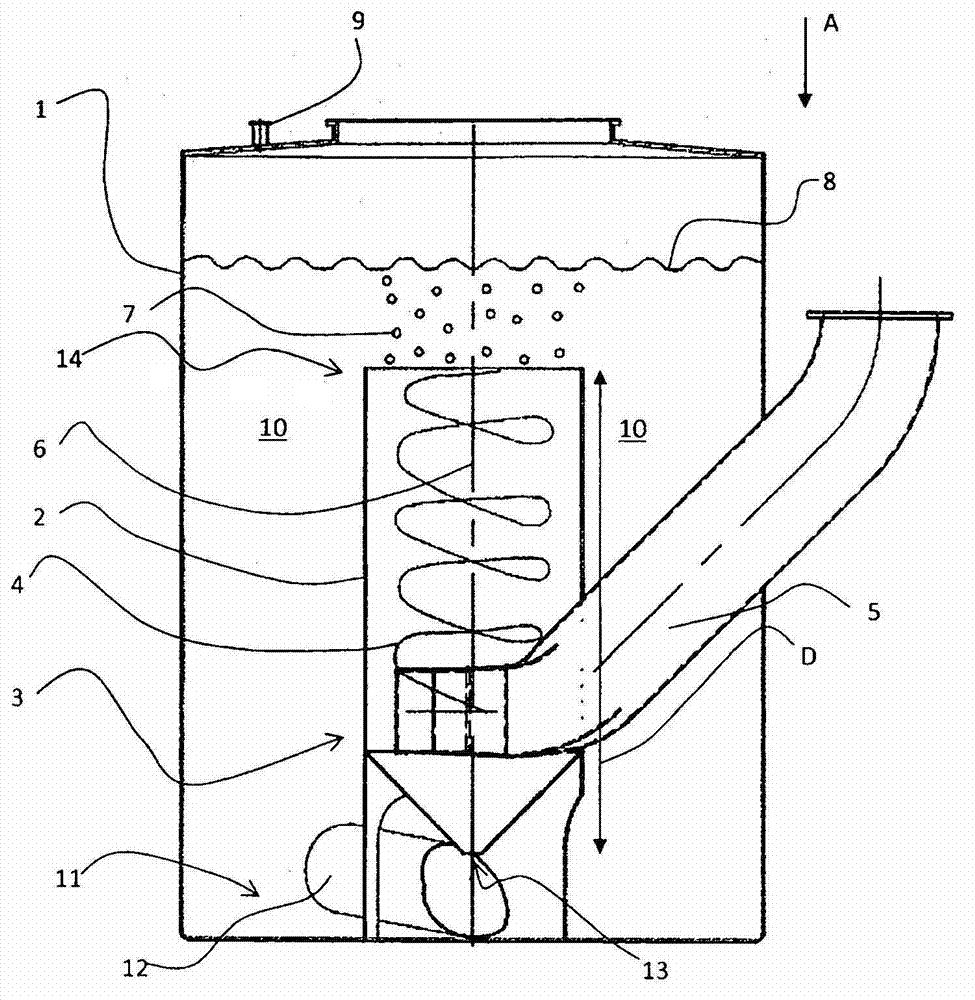

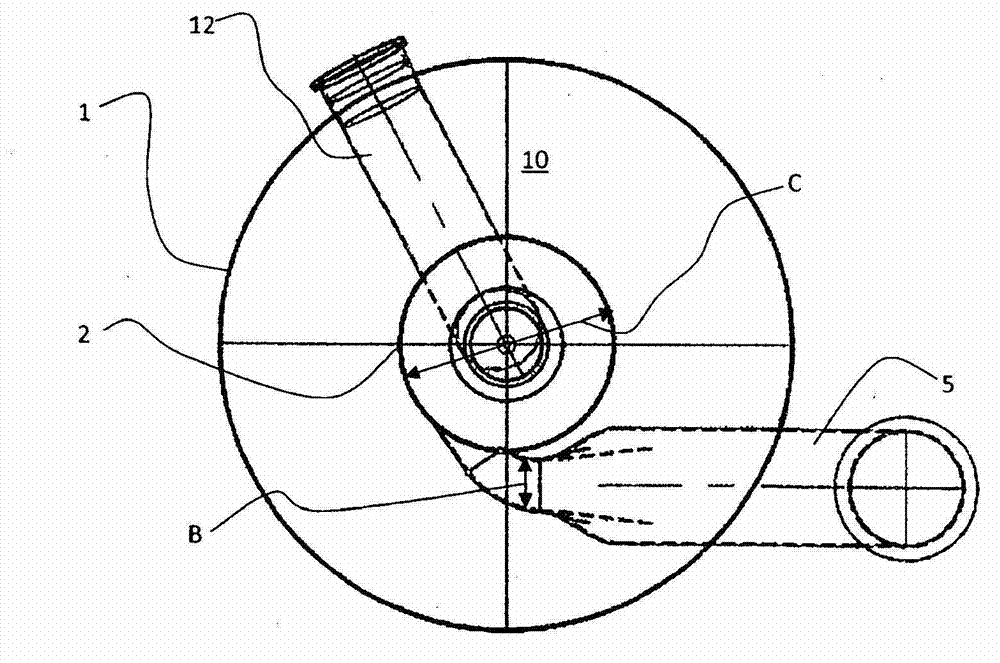

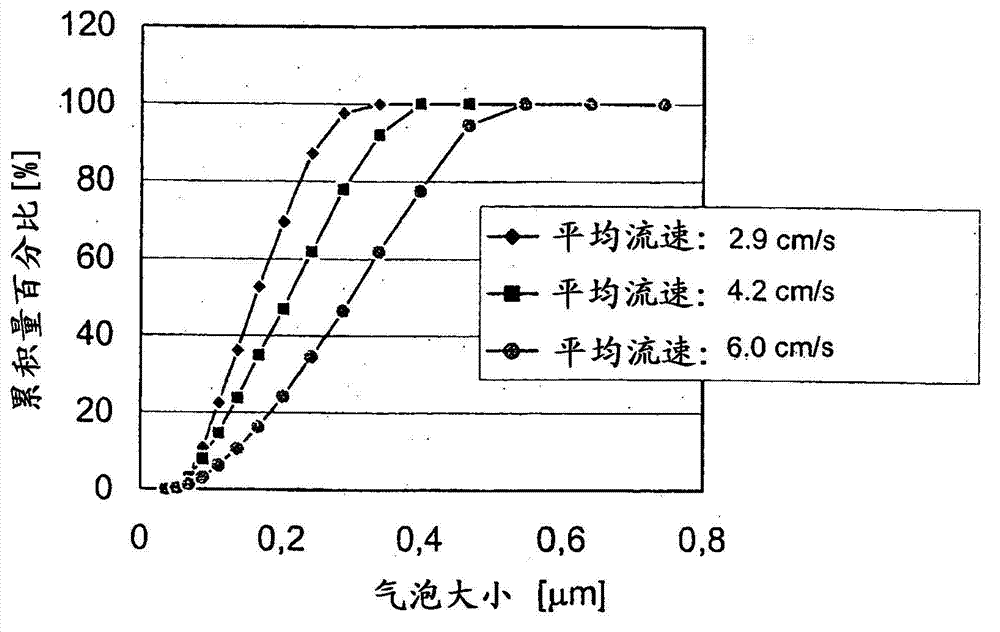

[0024] The functional capabilities of the devices according to the invention were tested under laboratory-level conditions. The device for degassing according to the invention is described in the following example. The degassing device according to this example comprises a degassing tank described in this example as a cyclone and a tank surrounding said cyclone. In the degassing plant according to this example the water is treated, in this case air is fed into the feed pipe of the cyclone. The cyclone is arranged concentrically in the tank so that the solution can be fed tangentially through the lower part of the cyclone. In this way, the solution undergoes a spiral upward movement in order to remove air bubbles at the top of the cyclone, some of which are carried along with the stream into the intermediate space between the tank and the cyclone. The cyclone used in the plant according to this example has a diameter of 300 mm and a height of 700 mm; these dimensions vary as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com